5 characteristics, 2 explosion proof enclosures, Characteristics – Detcon 1000_CO2 User Manual

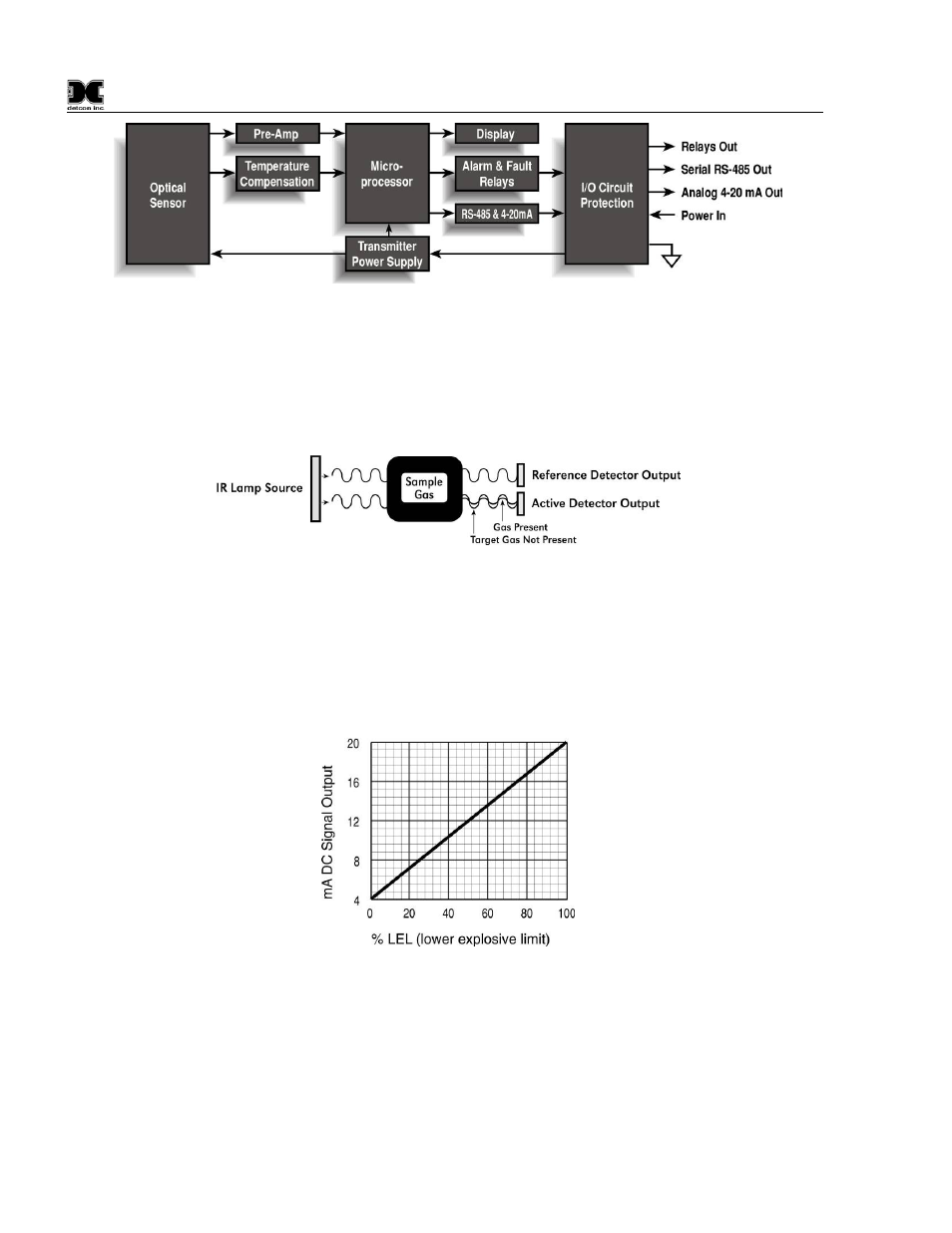

Page 8: Explosion proof enclosures, Figure 5 ir block diagram, Figure 6 principal of operation, Figure 7 ir response curve

Model 1000 CO2

Model 1000 CO2 Instruction Manual

Rev. 2.2

Page 4 of 28

Figure 5 IR Block Diagram

1.1.5 Characteristics

The NDIR optical sensor element maintains strong sensitivity to CO

2

. Typical zero calibration intervals would

be quarterly and typical span calibration intervals would be quarterly to bi-annual. However, actual field

experience is always the best determination of appropriate calibration intervals.

Figure 6 Principal of Operation

The NDIR optical sensor readings can be adversely affected by dust, dirt and oil mist accumulation as well as

severe corrosion. These deposits may reduce the optical reflectivity inside the sensor, and although accurate

readings are continually maintained, excessive loss in useable signal eventually gives way to noise and

unstable readings. The optical sensor may, over a period of time (3-7 years), lose its IR lamp source filament,

and in this case, an optical sensor modular replacement is required. The IR-640/IR-642 has an extensive list of

Fault Diagnostics to alert and pinpoint operational problems. See Troubleshooting, section 12.0.

Figure 7 IR Response Curve

1.2 Explosion Proof Enclosures

The sensors are packaged in cast metal explosion proof enclosures. The enclosures are fitted with a threaded

cover with glass lens window. Magnetic program switches located behind the transmitter module faceplate are

activated through the lens window via a hand-held magnetic programming tool allowing non-intrusive

operator interface with the sensor. All calibration and alarm level adjustments can be accomplished without

removing the cover or declassifying the area. Electrical classification is Class I; Groups B, C, D; Div. 1.