3 electrical connections, Electrical connections, Figure 10 unit overview – Detcon 1000_CO2 User Manual

Page 11: Sensor

Model 1000 CO2

Model 1000 CO2 Instruction Manual

Rev. 2.2

Page 7 of 28

changes. An insertion probe membrane device is advisable to use for pipeline sources with high levels of

condensates, mist, and contamination.

2. Whenever possible, the Sample Bypass flow control valve of the Genie membrane filter should be used to

minimize the sample lag time between the sample tap and the analyzer location. It can also be used as a

means to exhaust condensed liquids in the sample line away from the Genie filter and prevent a “loss of

flow” condition. Set a flow of 100-200cc/min. and vent to a safe area using ¼ O.D. tubing. Connect the

tubing to the Over-Pressure Relief valve and vent to a safe area. The pressure relief valve is set at Detcon

to open at 15-20psig. For convenience, the sample bypass and over-pressure relief can be vented together.

SAMPLE

FLOW

INLET

SAMPLE

10 PSIG (CONSTANT)

SAMPLE PRESSURE

INLET

AIR

AIR

INLET

SAMPLE

OUTLET

SAMPLE

AIR

FLOW

MODEL NO.

SERIAL NO.

INPUT VOLTAGE

FREQUENCY

CURRENT LOAD

AREA CLASSIFICATION

detcon inc.

3200 A-1 Research Forest Dr.

The Woodlands, TX 77381

www .detcon.com

PART NO.

MODEL NO.

SERIAL NO.

INPUT VOLTAGE

FREQUENCY

CURRENT LOAD

AREA CLASSIFICATION

detcon inc.

3200 A-1 Research Forest Dr.

The Woodlands, TX 77381

www .detcon.com

PART NO.

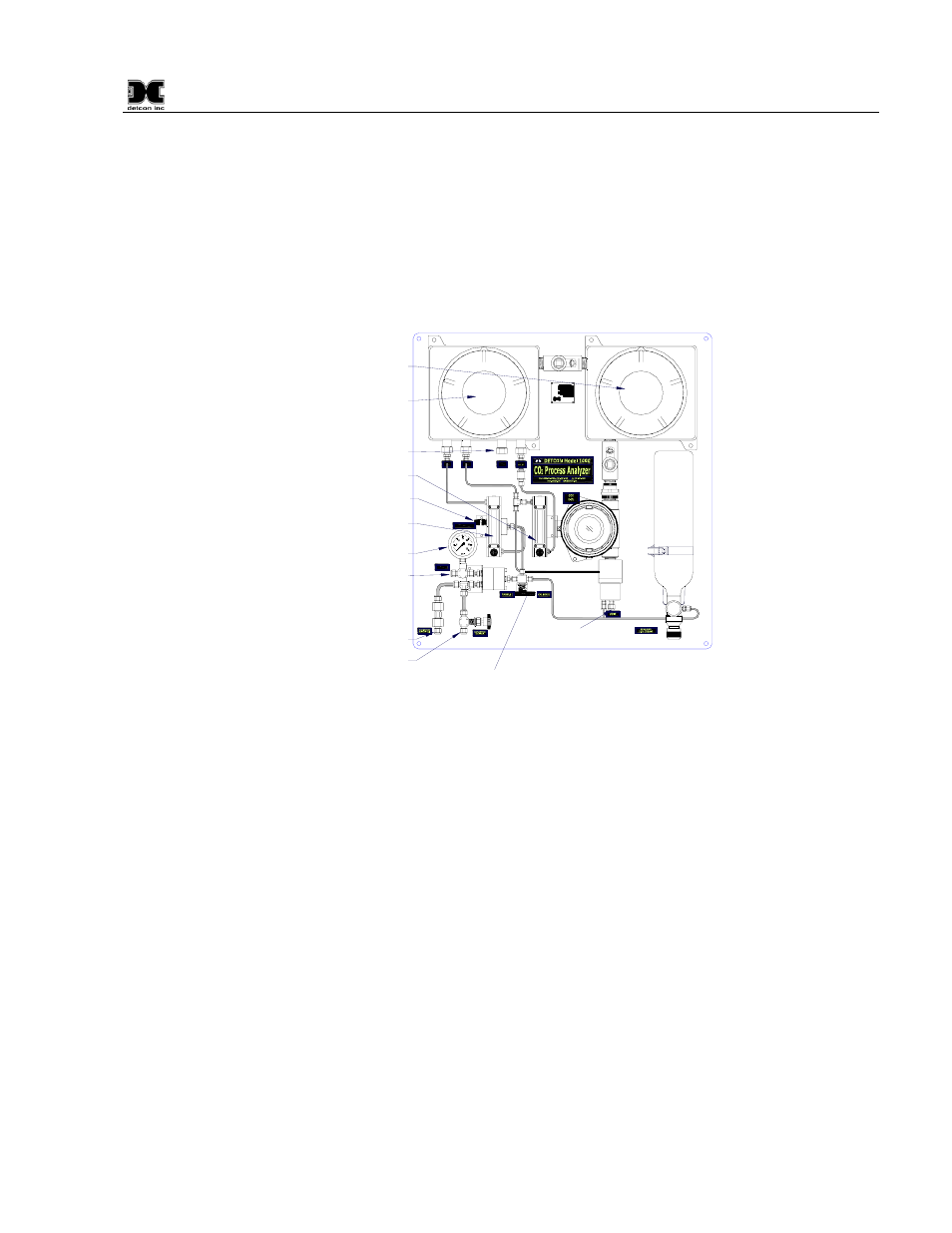

Over Pressure

Relief

Exhaust Vent

CO

2

3-Way Valve

Vent Port

CO

2

IR Sensor

NOTE: These can be combined into a single vent

Air Inlet Port

Sample Inlet Port

Sample Inlet

Pressure Gauge

CO

2

Sample or

Cal Gas Rotameter

Mass Flow Control

Air Flow Control

Rotameter

Flow Fault

and Pump Box

Power Supply Box

Figure 10 Unit Overview

3. Install a length of 1/4" OD stainless steel tubing from the vent port to an area deemed safe for venting as

shown below. The vent port should be separately vented from the over-pressure relief vent and the sample

by-pass vent.

3.3 Electrical Connections

1. For AC powered unit connect 110/220VAC to the terminal connector labeled “VAC IN” (JP8A) inside the

explosion-proof enclosure on the right. If applicable, connect 24VDC to the Terminal Connector Board

labeled “VDC IN” (JP7A). (Figure 11)

2. The 4-20mA and/or RS-485 signal outputs should be wired from the Terminal Connector Board and then

out the right side of the “Power Supply” explosion-proof enclosure. (Figure 11)

3. Alarm relay contacts are provided on the Terminal Connector Board for three alarms: Fault, Low, and

High (Figure 11). The contacts consist of common and choice of normally open or normally closed.

Contact output selections are jumper programmable on the sensor connector board. See IR-640/IR-642

wiring diagram for details. These connections also should be wired out of the right side of the “Power

Supply” explosion-proof enclosure (Figure 19). Sensor #1 termination corresponds to IR-640/IR-642 CO

2

Sensor.