Figure 12 alarm jumpers, Figure 13 rs485 id switches – Detcon 1000_CO2 User Manual

Page 13

Model 1000 CO2

Model 1000 CO2 Instruction Manual

Rev. 2.2

Page 9 of 28

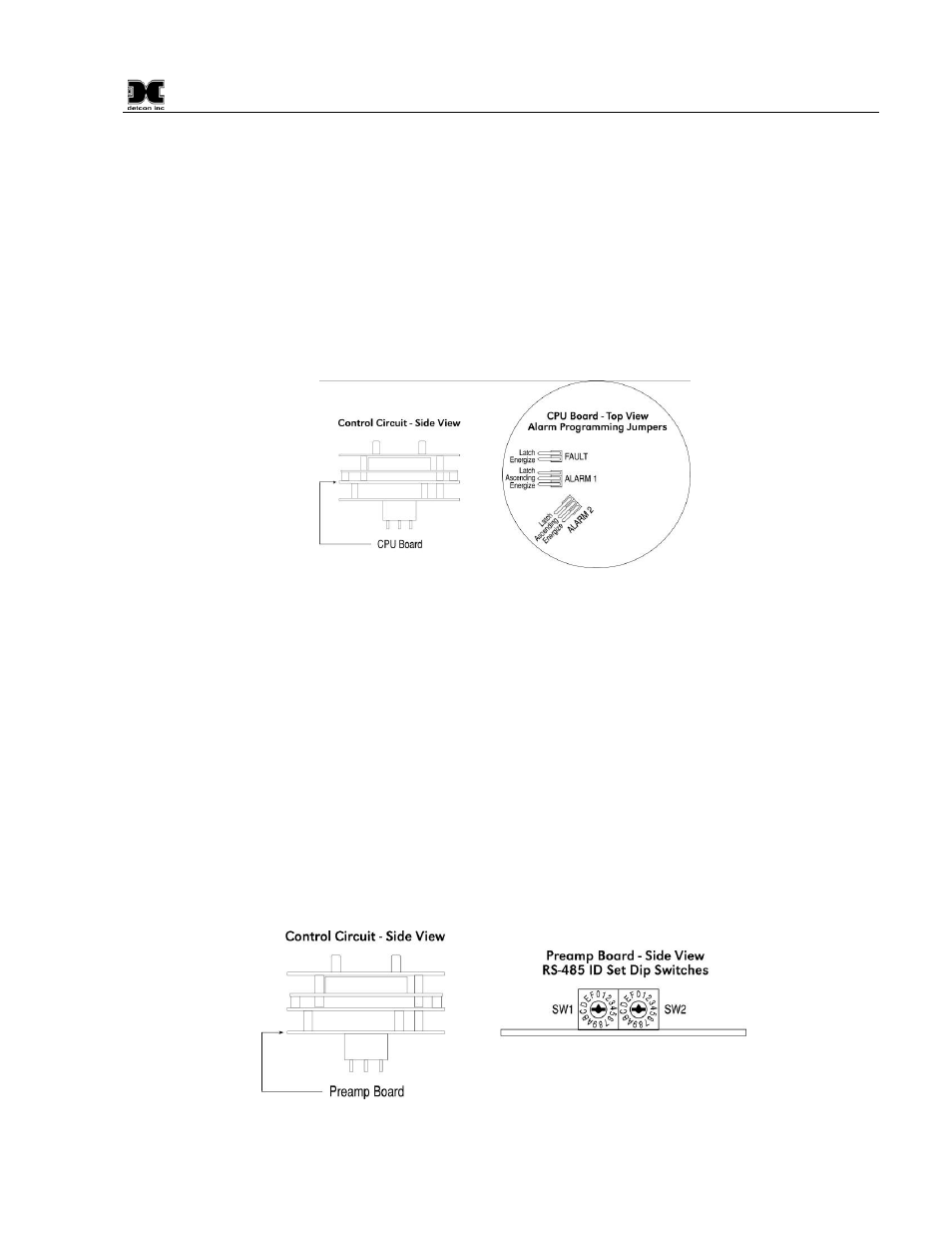

If a jumper tab is installed in the latch position, the alarm relay will be in the latching mode. The latching

mode will latch the alarm after alarm conditions have cleared until the alarm reset function is activated. The

non-latching mode (jumper removed) will allow alarms to de-activate automatically once alarm conditions

have cleared. The default Factory set-up for Alarm 1 and Alarm 2 relays is non-latching. The default factory

set-up for the Fault relay is latching.

If a jumper tab is installed in the energize position, that alarm relay will be in the energized mode. The

energized mode will energize or activate the alarm relay when there is no alarm condition and de-energize or

de-activate the alarm relay when there is an alarm condition. The de-energized mode (jumper removed) will

energize or activate the alarm relay during an alarm condition and de-energize or de-activate the alarm relay

when there is no alarm condition. The default Factory set-up for Alarm 1, Alarm 2, and Fault relays are de-

energized.

Figure 12 Alarm Jumpers

If a jumper tab is installed in the ascending position, the alarm relay will be in the ascending mode. The

ascending mode will cause an alarm to fire when the gas concentration detected is equal to or rises above the

alarm set point. The descending mode (jumper removed) will cause an alarm to fire when the gas

concentration detected is equal to or falls below the alarm set point. Except in special applications, H

2

S and

CO

2

monitoring will require alarms to fire in “ASCENDING” gas conditions. This is the default setting of the

Analyzer’s Alarms.

Any unused jumper tabs should be stored on the connector board on the terminal strip labeled “Unused

Jumpers”.

If applicable, set the RS-485 ID number via the two rotary dip switches located on the preamp board (see

below). There are 256 different ID numbers available, which are based on the hexadecimal numbering system.

If RS-485 communications are used, each sensor must have its own unique ID number. Use a jeweler’s

screwdriver to set the rotary dipswitches according to the hexadecimal table listed below. If RS-485

communications are not used, leave the dipswitches in the default position, which is zero/zero (0)-(0).

Figure 13 RS485 ID Switches

Replace the plug-in control circuit and replace the junction box cover.