Troubleshooting guide, Figure 16 plug-in sensor (bottom view) – Detcon FP-700 User Manual

Page 35

Model FP-700

FP-700 Instruction Manual

Rev. 3.0

Page 31 of 40

6. Troubleshooting Guide

Refer to the list of Failsafe Diagnostic features listed in Section 3.6.2 for additional reference in

troubleshooting activities. Listed below are some typical trouble conditions and their probable cause and

resolution path.

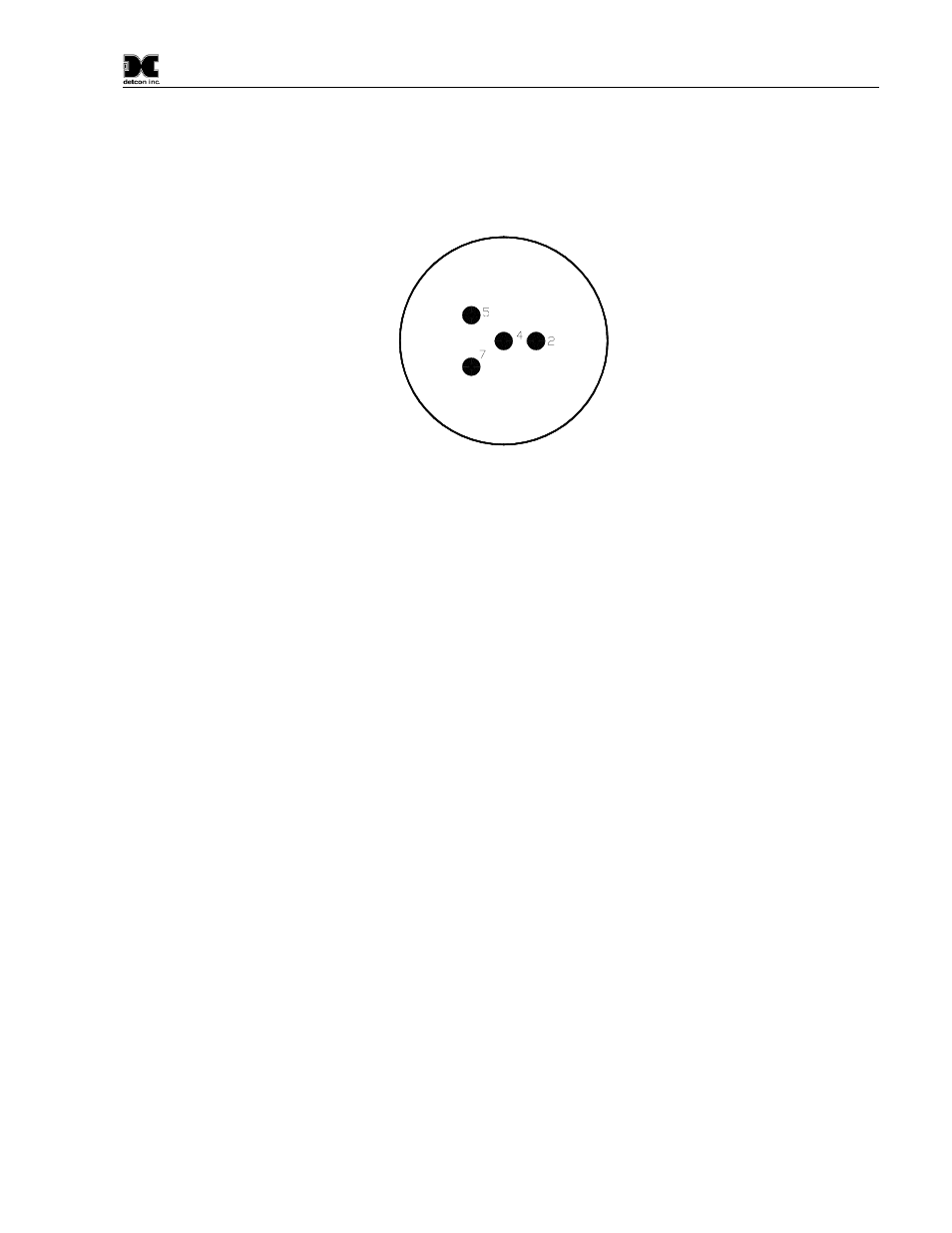

Figure 16 Plug-in Sensor (Bottom View)

Open Sensor Fault

Probable Cause: Plug-in sensor has failed.

Remove plug-in sensor and verify resistance between PIN 4 and PIN 5 and PIN 4 and PIN 2using an

ohmmeter. At room temperature, the normal reading range should be 2.5-3.5 ohms for both catalytic beads.

Replace plug-in sensor if either measurement is open circuit or significantly out-of range.

Zero Fault

Probable Causes: Plug-in sensor has drifted.

Perform AutoZero calculation per Section 3.4

Replace the plug-in sensor.

AutoSpan Calibration Faults – (Range, Stability and Clearing)

To clear any AutoSpan Calibration fault, the AutoSpan process must be completed successfully.

Range Fault

Probable Causes: Failed Sensor, Cal Gas not applied or not applied at appropriate time, or problems w/ cal gas

and delivery.

Check Bridge Voltage (should be 2.7 +/- 0.2VDC).

Check validity of span gas and flow rate (check MFG date on cal cylinder).

If using Splashguard with Integral Cal Port, must use Calibration Wind Guard or air movement can

compromise span gas delivery.

Make sure correct Cal Factor is set

Check for obstructions through stainless steel sinter element (including being wet).

Replace the plug-in sensor.

Stability Fault

Probable Causes: Failed Sensor, empty or close to empty Cal Gas Cylinder, or problems w/ cal gas and

delivery.