Service and maintenance, Calibration frequency, Visual inspection – Detcon FP-700 User Manual

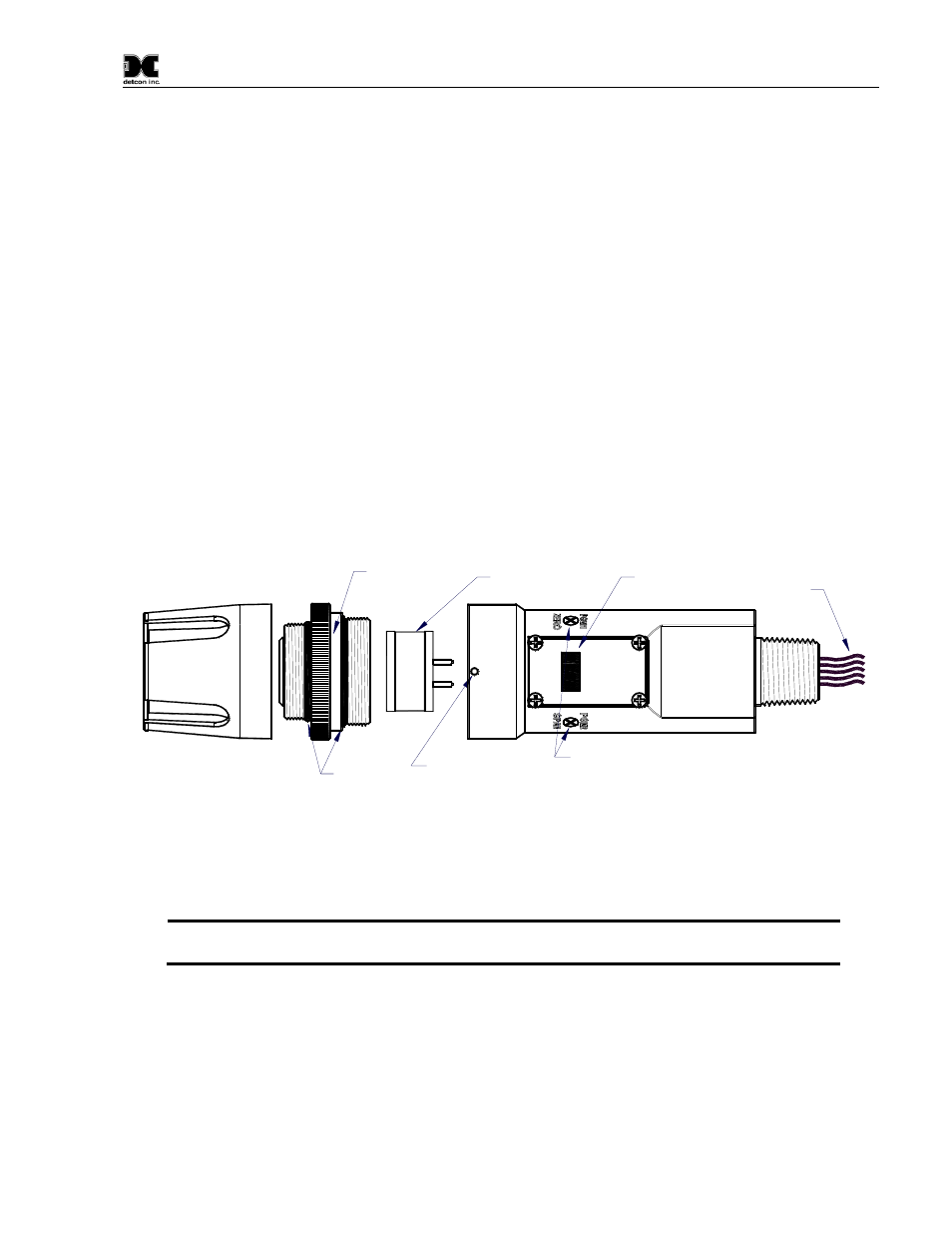

Page 33: Condensation prevention packet, Replacement of plug-in combustible gas sensor, Figure 15 sensor assembly, 1 calibration frequency, 2 visual inspection, 3 condensation prevention packet, 4 replacement of plug-in combustible gas sensor

Model FP-700

FP-700 Instruction Manual

Rev. 3.0

Page 29 of 40

5. Service and Maintenance

5.1 Calibration Frequency

In most applications, quarterly to biannual zero and span calibration intervals will assure reliable detection.

However, industrial environments differ. Upon initial installation and commissioning, close frequency tests

should be performed, weekly to monthly. Test results should be recorded and reviewed to determine a suitable

calibration interval.

5.2 Visual Inspection

The Sensor should be inspected annually. Inspect for signs of corrosion, pitting, and water damage. During

visual inspection, the Splash Guard should be inspected to insure that it is not blocked. Examine the porous

316SS flame arrestor within the sensor’s bottom housing for signs of physical blockage or severe corrosion.

Also, inspect inside the Junction Box for signs of water accumulation or Terminal Block corrosion.

5.3 Condensation Prevention Packet

A moisture condensation packet should be installed in every explosion proof Junction Box. The moisture

condensation prevention packet will prevent the internal volume of the J-Box from condensing and

accumulating moisture due to day-night humidity changes. This packet provides a critical function and should

be replaced annually. Detcon’s PN is 960-202200-000.

Housing Bottom

Locking Set-Screw

M

O

D

E

L

F

P

-7

0

0

d

e

tc

o

n

in

c

.

L

E

L

S

e

n

s

o

r

Splash Guard

O-Rings

Intelligent ransmitter Module (ITM)

Microprocessor controlled circuit

encapsulated in an explosion

proof housing.

d

e

tc

o

n

in

c

.

Bottom Housing

Assembly

Plug-In replaceable

H2S Sensor

Magnetic

Programming

Switches

Lens and LCD

Display

Interconnect Wiring

Figure 15 Sensor Assembly

5.4 Replacement of Plug-in Combustible Gas Sensor

a) Remove power to FP-700 sensor by lifting the + 24VDC wire in J-Box.

NOTE: It is necessary to remove power while changing the plug-in combustible gas sensor in

order to maintain area classification.

b) Use a M1.5 Allen wrench to release the locking setscrew that locks the ITM and bottom housing together

(One turn will suffice - Do not remove setscrew completely).

c) Remove splashguard. Unthread and remove the Bottom Housing from the ITM.

d) Gently pull the plug-in combustible gas sensor out of the ITM. Orient the new plug-in sensor so that it

matches with the female connector pins. It may be necessary to look from below to assure alignment is

correct. When properly aligned, press the sensor in firmly to make the proper connection.