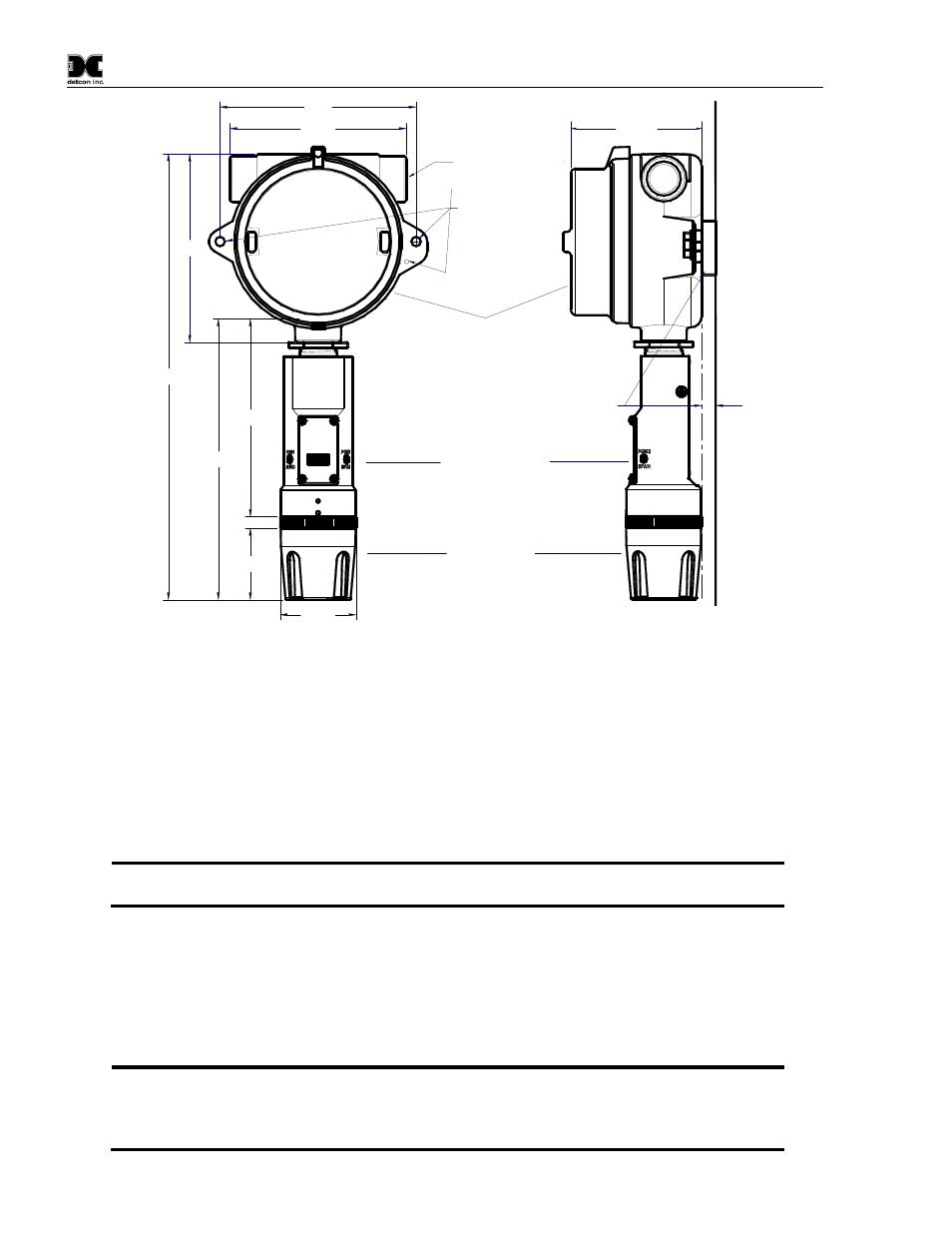

Electrical installation, Figure 9 outline and mounting dimensions, 5 electrical installation – Detcon FP-700 User Manual

Page 12

Model FP-700

FP-700 Instruction Manual

Rev. 3.0

Page 8 of 40

3.675"

3/4" NPT

Explosion Proof Enclosure

Junction-Box

Sensor Assembly

Splash Guard

(Detcon's Junction-Box shown)

2.125"

5.5"

4.95"

5.25"

5.53"

2"

12.5"

M

o

u

n

ti

n

g

B

o

lt

Use Spacers to move

the J-Box and Sensor

Assembly away from the

wall at least 0.25-0.5" to

allow access to Sensor

W

a

ll

(o

r

o

th

e

r

m

o

u

n

ti

n

g

s

u

rf

a

c

e

)

7.855"

Ø0.265" x2

S

p

a

c

e

r

Mounting Holes

8-32 Thread

Ground Point

detcon inc.

LEL Sensor

MODEL

FP-700

Figure 9 Outline and Mounting Dimensions

2.5 Electrical Installation

The Sensor Assembly should be installed in accordance with local electrical codes. The sensor assemblies are

CSA/NRTL approved (US and Canada) for Class I, Division 1, Groups B, C, & D area classifications, and are

ATEX Approved for Class I, Zone 1, Group IIB+H

2

area classifications.

Proper electrical installation of the gas sensor is critical for conformance to Electrical Codes and to avoid

damage due to water leakage. Refer to Figure 10 and Figure 11 for proper electrical installation.

NOTE: If a conduit run exits the secondary port, repeat the installation technique shown in

Figure 10.

In Figure 10, the drain allows H

2

O condensation inside the conduit run to safely drain away from the sensor

assembly. The electrical seal fitting is required to meet the National Electrical Code per NEC Article 500-3d

(or Canadian Electrical Code Handbook Part 1 Section 18-154). Requirements for locations of electrical seals

are covered under NEC Article 501-5. Electrical seals also act as a secondary seal to prevent water from

entering the wiring terminal enclosure. However, they are not designed to provide an absolute water-tight

seal, especially when used in the vertical orientation.

NOTE: The Detcon Warranty does not cover water damage resulting from water leaking into

the enclosure. However, since the electronics are 100% epoxy encapsulated, only the wire

terminations could get wet. Moisture could cause abnormal operation and possibly corrosion

to the terminal connections, but permanent damage to the sensor would not be expected.