Ultrasonic thickness, How to measure – DeFelsko PosiTector 200 v.3.1 Full Manual User Manual

Page 8

8

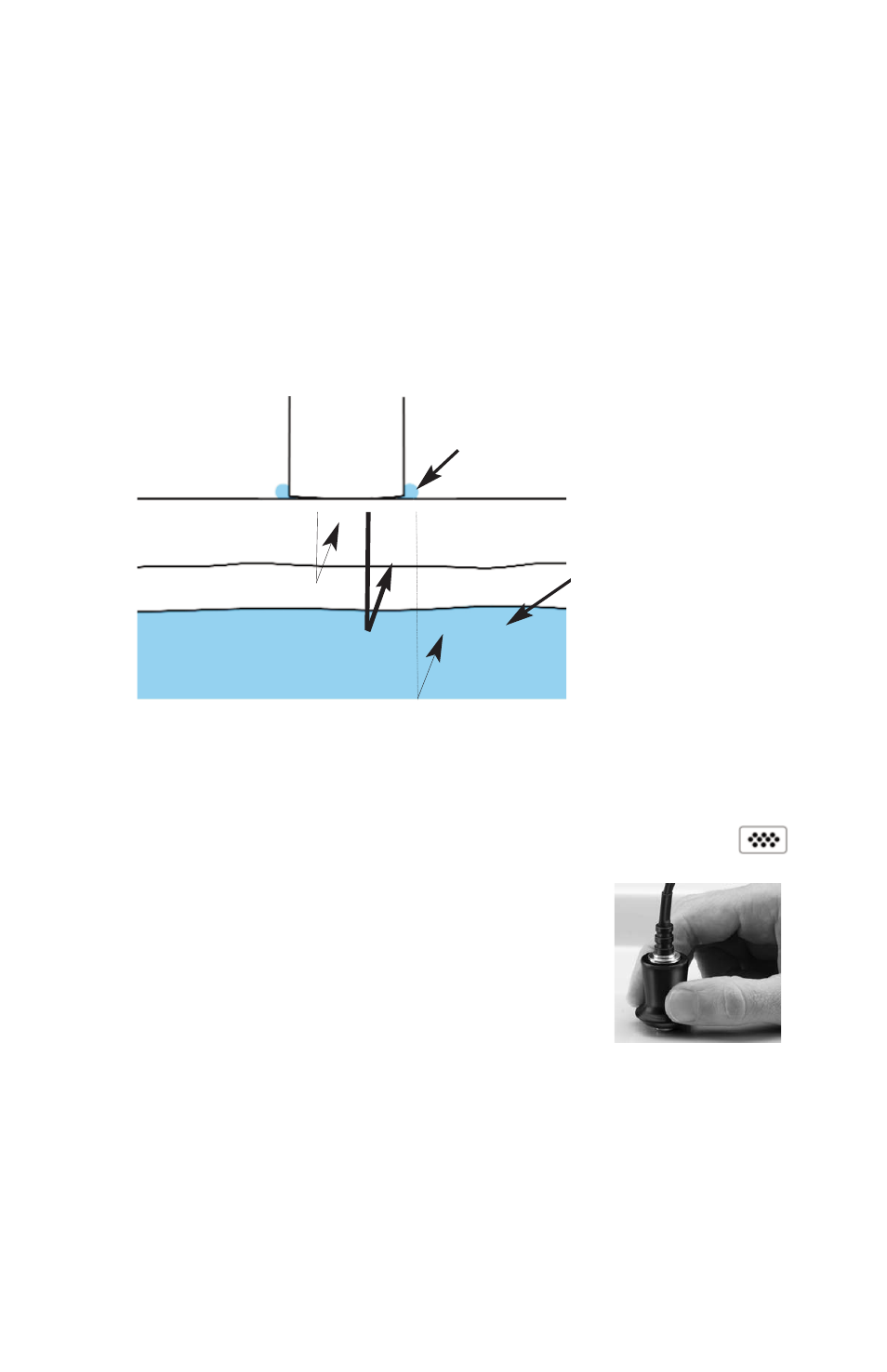

The PosiTector 200 probe emits a high frequency sound pulse

that travels into the coating via a coupling gel and reflects from

ANY surface that is different in density. Coating thickness readings

are obtained by measuring the time taken for the ultrasonic signal

to propagate from the probe to the coating/substrate interface and

back. The travel time is divided by two and multiplied by the

velocity of sound in the coating to obtain the thickness of the

coating.

Ultrasonic Thickness

Ultrasonic Thickness

Theory of Operation

Theory of Operation

Couplant

Probe

Coating 1

Substrate

Coating 2

The PosiTector 200

interprets the largest

“echo” within the

selected range as the

coating/coating or

coating/substrate echo.

How to Measure

How to Measure

1. Remove the protective rubber cap from probe.

2. Power-up Gage by pressing the center navigation

button.

3. Apply couplant (see pg. 5) to the surface of

the part.

4. Place the probe FLAT on the surface and

press down.

5. Lift the probe when you hear a double BEEP,

- OR - leave probe on the surface in the same location for

continuous measurements.

6. When completely finished, wipe the probe clean of couplant

then return the Gage to the protective pouch. There is no need

to disconnect the probe from the PosiTector during storage.