Motor replacement, Troubleshooting chart – Star Water Systems VPH SERIES User Manual

Page 6

6

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

E. Install the new rotary seal assembly:

1. Insert the ceramic seal and the rubber gasket into the

recess.

NOTE: To help facilitate installation, apply a light

coating of oil to the outside diameter of the rubber

gasket. Make certain that the ceramic seal is kept

clean and free of dirt and/or oil.

2. Slip the remaining parts of the rotary seal assembly

onto the motor shaft.

NOTE: Apply a light coating of oil to the inside diameter of

the rubber drive ring.

F. Replace the impeller and diffuser removed in Step B.

G. Reassemble the pump body to the motor and mounting

bracket.

MOTOR REPLACEMENT

CAUTION: Before attempting to replace the motor,

make certain that the power supply is disconnected

and the systems pressure is relieved.

A. The motor can be removed without disturbing the seal

assembly or hydraulic components of the pump. Make

certain that the service factor of the replacement motor

corresponds with the motor being replaced.

B. Remove four bolts that hold the motor to the motor

mounting ring.

C. Break the motor shaft free from the pump shaft by using

an 11/16” wrench on the pump shaft and a 9/16” wrench

on the flats of the motor shaft. Unthread motor shaft

while holding the pump shaft.

D. Reassemble the new motor.

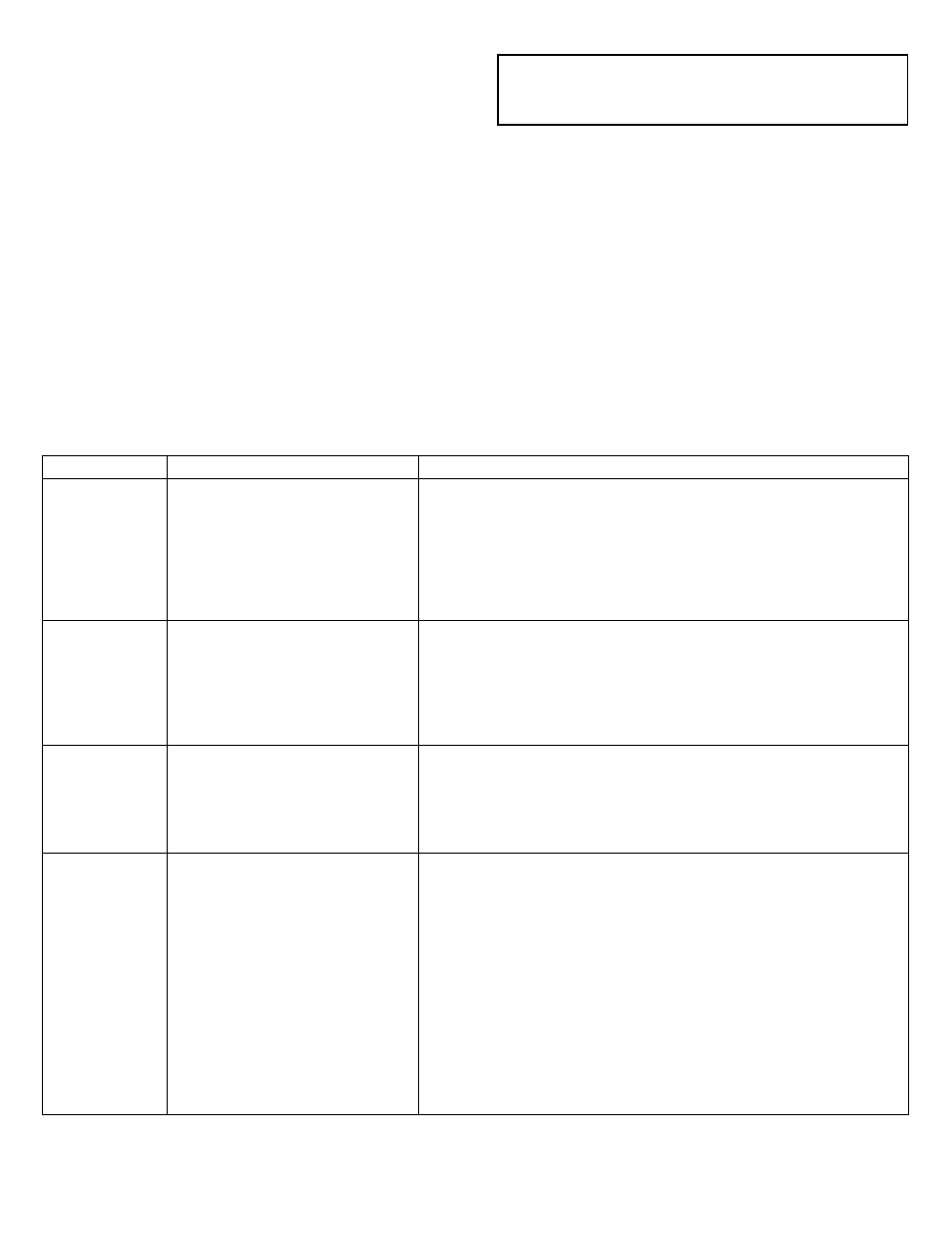

TROUBLESHOOTING CHART

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

PUMP WON’T

START OR RUN

1. Blown fuse

2. Low line voltage

3. Loose, broken or incorrect wiring

4. Defective motor

5. Defective pressure switch

6. Impeller or seal

7. Bad capacitor

1. If blown, replace with fuse of proper size. Use time delay fuses.

2. If voltage under recommended minimum, check size of wiring from main switch

on property. If OK, contact power company.

3. Rewire any incorrect circuits. Tighten connections, replace defective wires.

4. Replace

5. Adjust switch settings. Clean contacts with emery cloth, if dirty.

6. If impeller won’t turn, remove housing and locate source of binding.

7. Replace.

PUMP STARTS

AND STOPS

TOO OFTEN

1. Leak in pressure tank

2. Defective air volume control

3. Faulty pressure switch

4. Leak on discharge side of system

5. Leak on suction side of system

6. Leak in foot valve

1. Repair leaks or replace tank.

2. Clean or replace defective control.

3. Adjust switch settings. Clean contacts with emery cloth, if dirty.

4. Repair leaks as necessary.

5. Make sure above ground connections are tight. Then repeat test. If necessary,

pull piping and repair leak.

6. Repair or replace.

PUMP WON’T

SHUT OFF

1. Wrong pressure switch setting, or

setting “drift”

2. Defective pressure switch

3. Loss of prime

4. Low well level

5. Fouled ejector

1. Adjust switch to proper setting.

2. Replace switch if defective.

3. Reprime if necessary.

4. If undersized, replace pump or ejector.

5. Clean.

PUMP

OPERATES,

BUT DELIVERS

LITTLE OR NO

WATER

1. Low line voltage

2. System incompletely primed

3. Air lock in suction line

4. Undersized piping

5. Leak in air volume control or tubing

6. Leak on suction side of system

7. Low well capacity

8. Plugged ejector

9. Defective or plugged foot valve and/

or strainer

10. Worn or defective pump parts or

plugged impeller

1. If voltage under recommended minimum, check size of wiring from main switch

on property. If OK, contact power company

2. Reprime if necessary.

3. Rearrange pipingi to eliminate air lock.

4. Replace undersized piping or install pump with higher capacity.

5. Tighten all fittings and replace control if necessary.

6 Make sure above ground connections are tight. Then repeat test. If necessary,

pull piping and repair leak.

7. Close down the valve on the discharge side of pump to limit the flow of water, in

keeping with well capacity.

8. Clean and reinstall if dirty.

9. Clean, repair, or replace as needed.

10. Replace worn parts or entire pump. Clean parts if required.