Priming & adjustment, Maintenance, Rotary seal assembly replacement – Star Water Systems VPH SERIES User Manual

Page 5

5

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

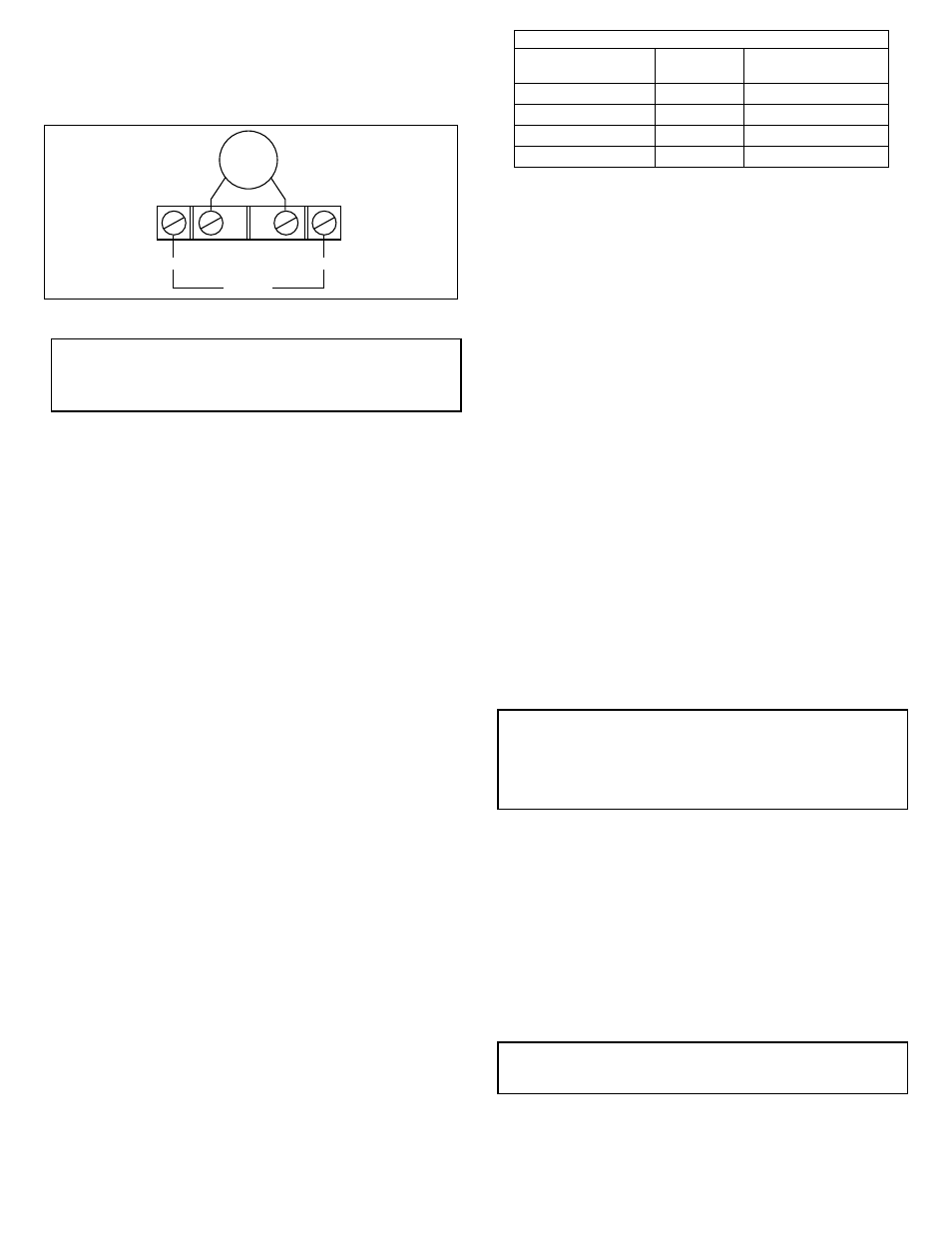

F. The pressure switch is wired to the motor by connecting

the motor lead to the two inside terminals of the pressure

switch. Connect the power lines to pressure switch

terminals marked L-1 and L-2.

IL0199

Motor

Load

Load

Load

Line 1

Line 1

Power

Supply

PRIMING & ADJUSTMENT

CAUTION: Before starting motor, the pump body

must be completely filled with water. Running the

pump dry will cause seal damage.

I. Pumps With Fully Automatic Control Valve

A.

Remove priming plug from pump. Fill pump body

completely with water until all air has been expelled.

Replace plug.

B. Start pump. If pump is properly primed, pressure will

build quickly and register on the pressure gauge. If

pressure does not build, repeat the priming operation.

ON DEEP WELL INSTALLATIONS, ALL AIR MUST BE

VENTED FROM THE DRIVE AND SUCTION PIPES AS

WELL AS THE PUMP BODY BEFORE THE PUMP WILL

PRIME. IT MAY BE NECESSARY TO FILL THE PUMP

BODY SEVERAL TIMES TO ACHIEVE PRIME.

C. Once prime is achieved, unit will adjust automatically to

the average operating pressure.

II. Pumps With Semi-Automatic Control Valve

A. Remove priming plug from pump. Fill pump body

completely with water until all air has been expelled.

Replace plug.

B. Screw adjusting stem on control valve all the way in, then

start the pump. If the pump is properly primed, pressure

will build quickly and register on the pressure gauge. If

pressure does not build, repeat the priming operation.

C. With the pump operating at high pressure and no

pressure in the tank (two or more faucets open) slowly

unscew the adjusting stem until maximum flow is

obtained. The case pressure at this point will be the

average operating pressure and should agree with the

chart shown below.

D. If the control valve is opened too far, a slight cavitation

noise will be noticeable and still further opening will

cause the pump to lose prime.

AVERAGE OPERATING PRESSURE

MODEL NO.

SETTING

HP

PRESSURE

VS, VA207P

3/4

46 PSI

VS, VA210P

1

57 PSI

VS, VA215P

1-1/2

72 PSI

VPH10

1

47 PSI

NOTE: PUMP WILL NOT PRIME IF THERE IS ANY

LEAKAGE IN THE SUCTION PIPING.

III. Pumps Installed In A Horizontal Position

A. “VA” and “VS” pumps can be installed horizontally by

using the optional 135276 pump base.

B. If installed horizontally, prime through the priming port of

the pump body.

C. By following this procedure, the entire pump cavity can

be filled with water and air will be expelled more readily.

MAINTENANCE

A. LUBRICATION

The pumps and motors require no lubrication. The ball

bearings of the motor have been pre-lubricated and

under normal operating conditions should require no

further greasing.

B. FREEZING

Drain the entire system if there is danger of freezing. A

drain plug is provided at the bottom of the pump case for

this purpose.

ROTARY SEAL ASSEMBLY

REPLACEMENT

CAUTION: Make certain that the power supply is

disconnected before attempting to service the unit!

The rotary seal assembly must be handled carefully

to avoid damaging the precision lapped faces of

the sealing components.

A. Disengage pump body from motor and mounting ring.

B. Remove diffuser and unthread impeller from the pump

shaft.

NOTE: To prevent the shaft from rotating when removing

the impeller, use an 11/16” open end wrench on the hex

of the pump shaft.

C. The carbon seal face, friction ring, and stainless steel

shell & spring of the rotary seal will come loose at this

time. Use a screwdriver (or similar instrument) to pry the

ceramic seal and rubber gasket from the recess of the

mounting bracket.

CAUTION: Be careful not to damage the motor

shaft or recess surface.

D. Clean the recess and pump shaft thoroughly.