Preliminary considerations, Installation – Star Water Systems VPH SERIES User Manual

Page 3

3

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

PRELIMINARY CONSIDERATIONS

I. Location

A. Pump can be located at the well or can be offset some

distance away from the well. For best performance, it

should be located as close to the well as possible.

B. Location can be in the basement, a pit below ground, or

in a pump house above ground.

C. Ventilation and drainage must be provided to prevent

damage from moisture to the motor and pressure switch.

D. The pump and all piping must be protected from freezing.

E. Pump and pipe line must be drained when not in use if

there is any danger of freezing.

II. Well Conditions

A. New wells should be pumped clean of all sand and

foreign matter before installing the pump, or damage may

result to the operating parts.

B. The foot valve should be installed a minimum of five feet

from the bottom of the well to prevent sand, mud or other

foreign matter from entering the system.

C. The well must be capable of furnishing a sufficient

quantity of water to satisfy the demands of the pump and

personal needs. The water level must not draw down

below the maximum rated depth of the pump, or loss of

capacity and prime will result.

D. For weak well installations, see Paragraph A under Deep

Well (Double Pipe System) installations.

E. For sanitary reasons, install a well seal or pitless adapter

as required and in accordance with local and state

codes.

III. Piping

A. Old or badly scaled pipe should not be used, because

dislodged flakes of scale can cause stoppage of the

ejector nozzle and malfunction the entire system.

B. Use only pipe in good condition, free of rust and

scale. Threads should be sharp, cleanly cut and with a

minimum of two threads remaining when connection is

completely drawn up.

C. On galvanized steel pipe installations, the ends should

be reamed to ensure maximum capacity.

D. All joints and connections should be doped (male threads

only) and drawn up tightly.

CAUTION: THE ENTIRE SYSTEM MUST BE AIR

AND WATER TIGHT FOR EFFICIENT OPERATION

IV. Type of Pipe

A. Plastic or galvanized steel pipe may be used in the

installation of jet pumps.

B. Plastic pipe must have a minimum pressure rating of 160

P.S.I.

C. DO NOT USE PLASTIC PIPE IN THE WELL ON

SINGLE PIPE EJECTOR INSTALLATIONS.

V. Well To Pump Piping

A. All offset piping should slope upwards from well to pump.

B. Avoid dips or pockets in offset piping, or air will

accumulate at high points and make priming difficult.

C. Install unions at pump and at well to aid in servicing.

D. Allow enough room around pump and piping installation

for using pipe wrenches, and for service and installation.

E. Do not use piping of sizes smaller than those listed in

Chart 1, or pump will not operate properly.

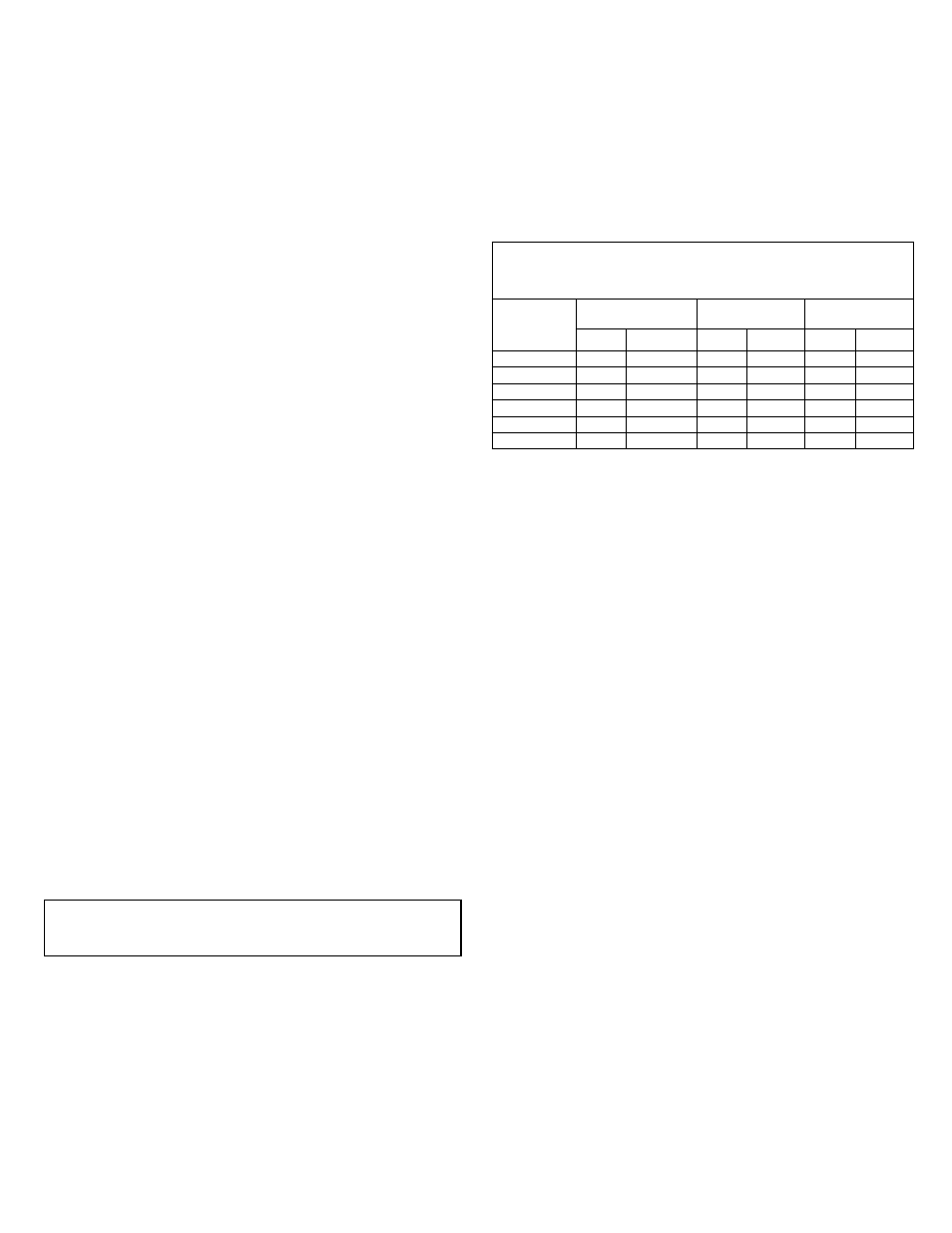

CHART I

PIPE SIZES REQUIRED FOR HORIZONTAL

PIPING BETWEEN PUMP AND WELL

Distance:

Well to

Pump

3/4 HP

1 HP

1-1/2 HP

Suc.

Press.

Suc.

Press.

Suc.

Press.

0’ - 25’

1-1/4”

1”

1-1/4”

1”

1-1/4”

1”

25’ - 50’

1-1/4”

1-1/4”

1-1/4”

1-1/4”

1-1/4”

1-1/4”

50’ - 75’

1-1/4”

1-1/4”

1-1/4”

1-1/4”

1-1/4”

1-1/4”

75’ - 100’

1-1/2”

1-1/4”

1-1/2”

1-1/4”

1-1/2”

1-1/4”

100’ - 125’

1-1/2”

1-1/2”

1-1/2”

1-1/2”

1-1/2”

1-1/2”

125’ - 150’

1-1/2”

1-1/2”

1-1/2”

1-1/2”

1-1/2”

1-1/2”

NOTE - USE PIPE JOINT COMPOUND ON

EXTERNAL THREADS OF ALL CONNECTIONS

INSTALLATION

I. Deep Well (Double Pipe System)

Application - Where the inside diameter of well is 3-1/2

inches or larger. (See illustration C & D).

A. Attach the foot valve to the ejector using a galvanized

steel or plastic nipple. Add sufficient pressure pipe (1”)

and suction pipe (1-1/4”) to submerge ejector 10 to 15’

below pumping water level, making certain foot valve is

at least 5 feet from bottom of well. If pressure pipe and

suction pipe of the same diameter are used, be sure to

identify them clearly so that they will be connected to the

proper tappings of the pump.

If a known weak well exists, replace nipple with 34 feet of

1” tail pipe between the ejector and the foot valve. This

will provide a continuous source of water for the pumping

system.

B. Check pipe and foot valve for leaks by filling pipes with

water. A continuous loss of water indicates a leak in the

piping, foot valve or unions, and must be corrected.

C. If no leaks are found, connect pressure and suction pipes

from well to pump using piping of the same diameter as

the suction pipe (1-1/4”) and pressure pipe (1” ) tappings

of the pump. For long offset distances, refer to Chart I.

for the proper pipe size.

D. Unions in suction and discharge piping near pump and

well will aid in servicing. Leave enough surrounding

room so that wrenches can be used without difficulty.