Read these instructions carefully, General safety information, Motor specification chart – Star Water Systems VPH SERIES User Manual

Page 2

2

95 North Oak Street • Kendallville, IN 46755 • 260-347-1600 © Copyright 2013. All rights reserved.

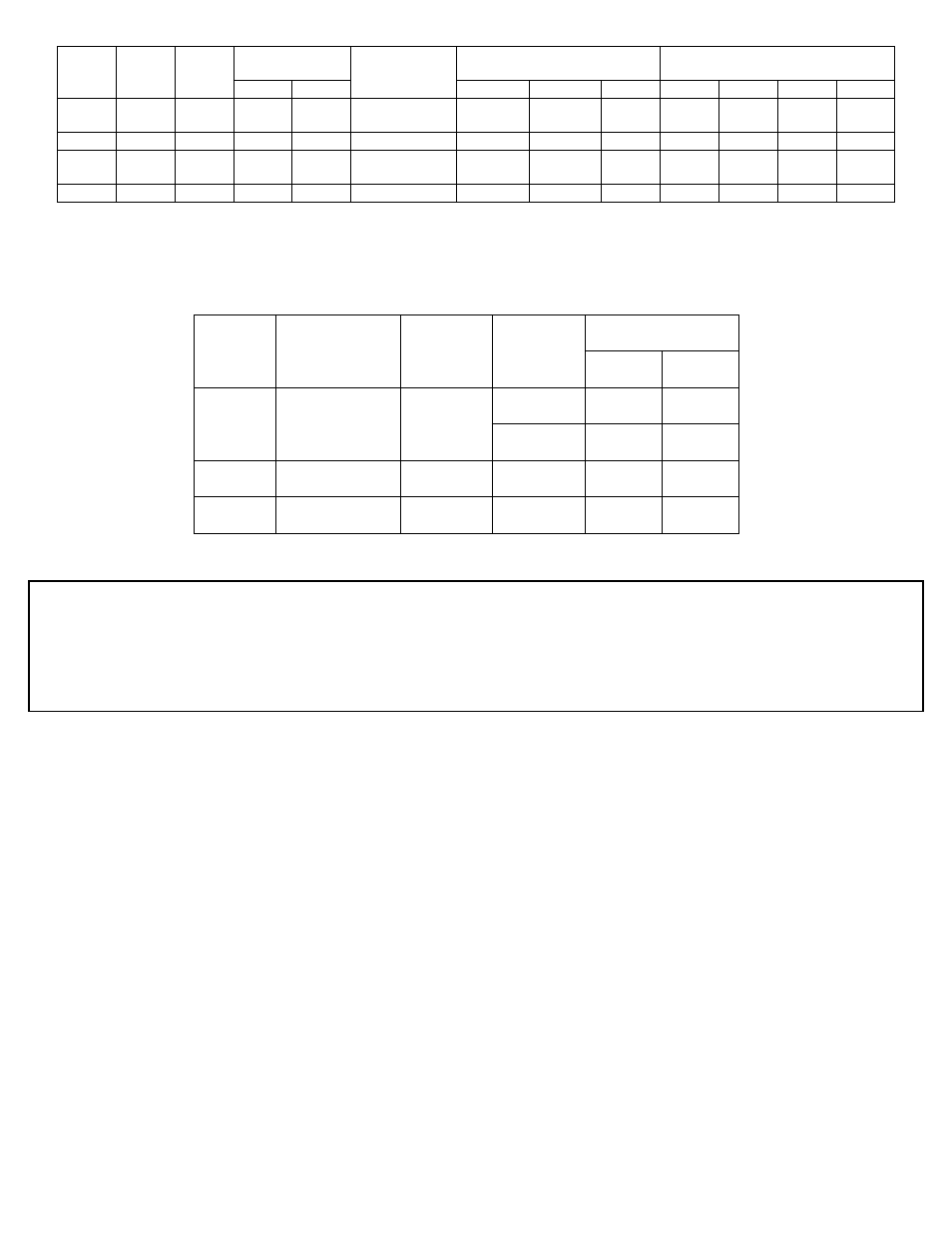

MOTOR SPECIFICATION CHART

PUMP

MODEL

NO.

HP

STG.

NAMEPLATE

MAX AMPS

MOTOR

CONNECTED

FOR

TAPPING SIZE INCHES

DIMENSIONS INCHES

115V

230V

DISCHG. SUCTION PRESS.

H

W

L

WT.

VS207P

VA207P

3/4

2

18

9

230V

1”

1-1/4”

1”

17”

9-1/4”

15-1/8”

67 lb.

VPH10

1

1

18

9

230V

1”

1-1/4”

1”

15-1/2”

6-1/2”

14-1/2”

56 lb.

VS210P

VA210P

1

2

21

10.5

230V

1”

1-1/4”

1”

17-5/8”

9-1/4”

15-1/8”

72 lb.

VS215P

1-1/2

2

25

12.5

230V

1”

1-1/4”

1”

18-1/8”

9-1/4”

15-1/8”

76 lb.

All motors are single phase 60 Hz., 3450 RPM.

Motor can be changed to either 115V or 230V by following diagram on motor decal.

Pressure switch settings are 30 - 50 PSI for the above models.

EJECTOR SPECIFICATIONS AND WELL ADAPTER SELECTION CHART

EJECTOR

ORDER

NO.

EJECTOR

DESCRIPTION

EJECTOR

DROP PIPE

TAPPING

WELL SIZE /

DROP PIPE

WELL ADAPTER

REQUIRED

PACKAGE

NO.

TYPE

SP20BL

2” Brass, Leather

1” F

1-1/4” M

2” x 1”

129719

127025

Straight

Rt. Angle

2” x 1-1/4”*

129720

129723

Straight

Rt. Angle

SP20CL

2” Cast Iron,

Leather

1” F

2” x 1”

129719

127025

Straight

Rt. Angle

SP22CL

2” Cast Iron,

Leather

1-1/4” M

2” x 1-1/4”

129720

129723

Straight

Rt. Angle

*129205 1-1/4” turned coupling required. Order separately.

READ THESE INSTRUCTIONS CAREFULLY

Read these installation instructions in detail before installing your pump. Be sure to check the following:

1. Be certain the motor is connected for the correct line voltage being used (check motor nameplate).

2. Be certain the pump is completely primed before starting. Otherwise damage may occur to the seal.

EVERY pump is tested before leaving the factory, and its performance depends largely on the installation.

GENERAL SAFETY INFORMATION

A. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC) and the Occupational

Safety and Health Act (OSHA).

B. Replace or repair damaged or worn cords immediately.

C. Do not kink power cable and never allow the cable

to come in contact with oil, grease, hot surfaces, or

chemicals.

D. Protect the power cable from coming in contact with

sharp objects.

E. Be careful when touching the exterior of an operating

motor--it may be hot enough to be painful or cause injury.

With modern motors, this condition is normal if operated

at rated load and voltage. Modern motors are built to

operate at higher temperatures.

F. Make certain that the power source conforms with the

requirements of your equipment.

G. Always disconnect power source before performing any

work on or near the motor or its connected load. If the

power disconnect point is out-of-sight, lock it in the open

position and tag it to prevent unexpected application of

power. Failure to do so could result in fatal electrical

shock.

H. Do not handle the pump with wet hands or when

standing in water, as fatal electrical shock could occur.

Disconnect main power before handling unit for ANY

REASON!

I. Unit must be securely and adequately electrically

grounded. This can be accomplished by wiring the unit

to a grounded metal-clad raceway system or by using a

separate ground wire connected to the bare metal of the

motor frame or other suitable means.

J. WARNING:

Risk of electric shock. This pump has not

been investigated for use in swimming pool areas.

K. WARNING:

This product contains chemicals known to

the State of California to cause cancer and birth defects

or other reproductive harm.

L. NOTE:

Pumps with the “CSA” mark are tested to UL

standard UL778 and certified to CSA standard C22.2

No. 108.