Star Water Systems SJ05SAT20H User Manual

Page 6

© 2014 Star Water Systems. All rights reserved. 10

© 2014 Star Water Systems. All rights reserved. 11

PUMP TO HOUSE CONNECTION (DISCHARGE PIPE)

PUMP ELECTRICAL CONNECTIONS

WARNING:

• Always disconnect pump from electricity before performing any work on the motor.

• Under-sized wiring can cause motor failure and even fire. Use proper wire size specified in the

Wire Size Chart.

• Replace damaged or worn wiring cord

immediately.

• Do not kink power cable and never allow the

cable to come in contact with oil, grease, hot

surfaces, or chemicals.

• The pump must be properly grounded using

the proper wire cable with ground.

CAUTION:

• Protect the power cable from coming in

contact with sharp objects.

• All wiring should be performed by a qualified

electrician in accordance with the National

Electric Code and local electric codes.

• Connect the pump to a separate electrical

circuit with a dedicated circuit breaker. Refer

to the Wire Size Chart for proper fuse size.

WIRE SIZE CHART

Distance from

Motor to Meter

Recommended Copper Wire

and Fuse Sizes

Single Phase Motors

1/2 HP

1 HP

115

Volt

230

Volt

115

Volt

230

Volt

0-50 Ft.

50-100 Ft.

100-150 Ft.

150-200 Ft.

200-300 Ft.

14

12

10

8

*

14

14

14

14

12

12

10

8

*

*

14

14

14

12

10

Fuse Size (Amps)

15

15

30

15

(*)

Not economical to run in 115 V, use 230 V

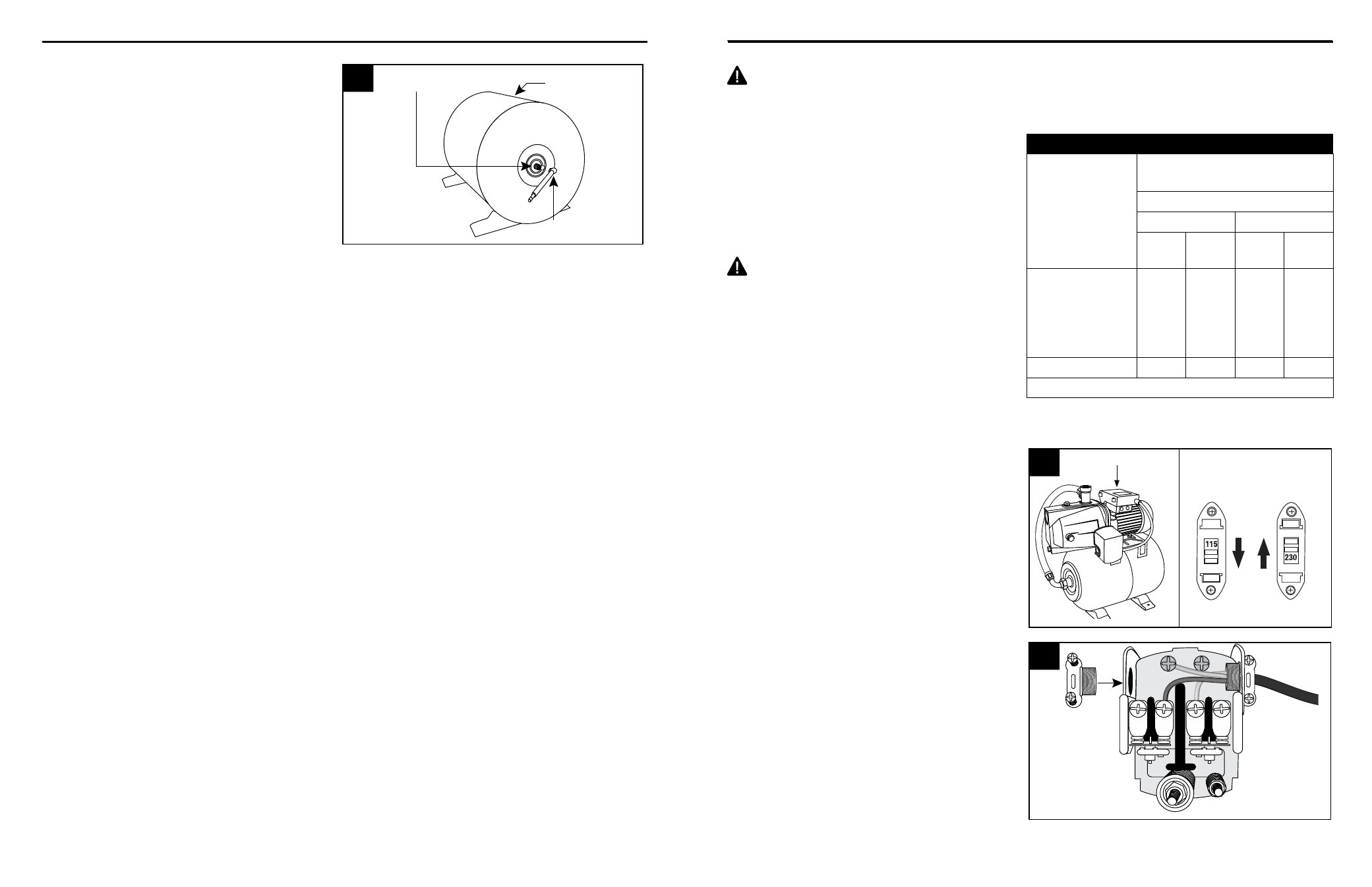

5.

IMPORTANT: Air pressure in the tank

must be 2 PSI lower than the “cut-in” of the

pressure switch. Pump/tank has a 20/40

PSI pressure switch, so tank pressure must

be set at 18 PSI. Locate the air valve/stem

on the tank and check pressure with a tire

gauge (not included). If air needs to be

removed, press down on valve to bleed air

off. Use a tire pump or air compressor to

add air if needed.

Tire gauge

Tank

Air Valve/Stem

5

Wiring the pressure switch

CAUTION: Make certain that the power source

matches the pump requirements. This pump has

a dual voltage motor and can run on 115 V or

230 V.

Pump/tank is pre-set at the factory to run on

230 V.

1. To change pump voltage, remove the square

voltage switch cover at the top of pump/tank

and move the voltage switch as shown.

1

115 V

Setting

230 V

Setting

2. To connect the pressure switch, remove the

switch cover and insert an electrical wire

strain relief (not included) into the opening in

the side of the pressure switch.

IL1376

Wire from

motor

Pressure

Switch

Strain

Relief

2