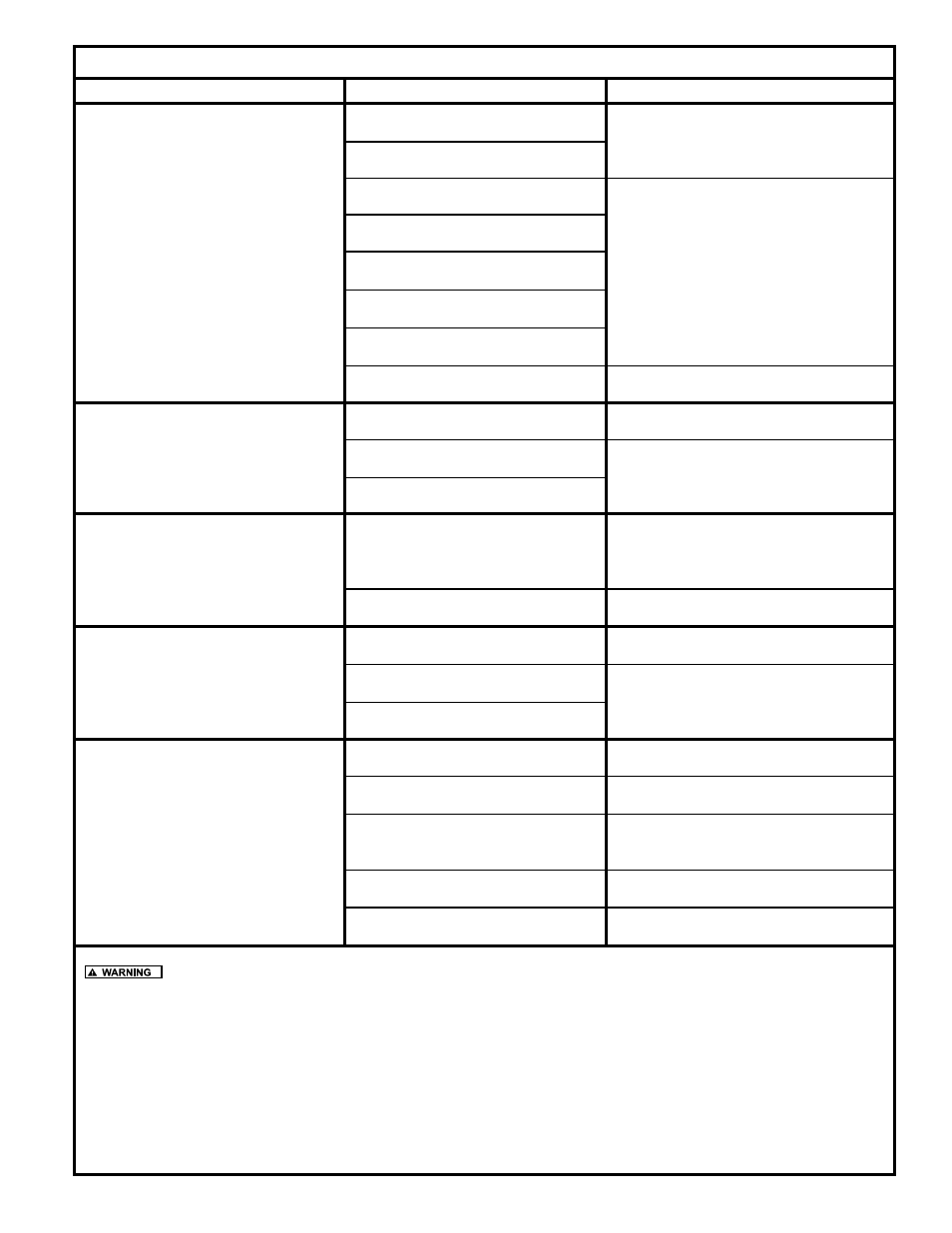

Trouble shooting guide, Condition possible cause remedy – Star Water Systems S1108 User Manual

Page 7

7

© Copyright 2002. All rights reserved.

Trouble Shooting Guide

Blown fuse.

Low voltage.

Thermal overload open.

Impeller bound.

Motor or wiring shorted.

Switch defective.

Damaged float.

Float assembly bound.

Incorrect voltage.

Impeller bound.

Motor shorted.

Short cycling (No check valve in dis-

charge line to prevent water from drain-

ing back into pit).

Defective float.

Debris under float.

Switch defective.

Switch out of adjustment.

Weep hole plugged (Air-locked).

Obstruction in discharge line.

Discharge head exceeds capacity.

Low voltage.

Discharge line frozen.

Have a qualified electrician check circuit.

Contact an Authorized Service Station.

Check for debris around float.

Have qualified electrician check circuit.

Contact an Authorized Service Station.

Refer to STEP 5 for installation of check valve.

Contact an Authorized Service Station.

Remove debris as necessary.

Contact an Authorized Service Station.

Clear weep hole as necessary.

Clear lines as necessary.

Refer to pump performance chart on page 2,

or contact factory.

Have qualified electrician check circuit.

Clear and protect from freezing (See STEP 6).

Condition

Possible Cause

Remedy

A. PUMP WILL NOT START OR RUN.

B. PUMP TRIPS OVERLOAD OR

BLOWS FUSE.

C. PUMP STARTS AND STOPS TOO

OFTEN.

E. PUMP WILL NOT SHUT OFF.

F. PUMP OPERATES BUT DELIVERS

LITTLE OR NO WATER.

Before servicing a pump, always shut off the main

power breaker and then unplug the pump - making sure you are

not standing in water and are wearing insulated, protective-sole

shoes. Under flooded conditions, contact your local electric

company or a qualified licensed electrician for disconnecting

electrical service prior to pump removal.

If the above checklist does not solve the problem, consult our

Technical Service Department. Do not attempt to service or

otherwise disassemble pump.