3 factory settings, 4 types is 12-al/s with built-in scanner, 1 function – LumaSense Technologies IS 12-Al/S User Manual

Page 20

IS 12 AI & IS 12-AI/S

Instrument settings 20

3) ENT

If a parameter is changed with the arrow keys, the new value must be

confirmed by pushing the ENT key. If it is not confirmed with ENT, the

instrument is still operating with the previous parameter value. If no key

is pressed for approx. 30 s, the display changes to the temperature

indication.

Limit contacts

Two limit switches can be set. If the measuring temperature exceeds the

adjusted limit contact temperature, the LED S1 or S2 displays the switch

status.

Scale °C or °F

The LED indicates the temperature scale in °C or °F.

Parameter

indicator

LEDs indicate which pyrometer parameter is selected for reading or

changing.

4.3 Factory Settings

Emissivity ( ) = 1.000

Exposure time (t

90

/ s) = off

Clear time (t

CL

) = off

Sub range (from / to) same as temperature range

Analog output (0 / 4 mA) = 0 ... 20 mA

Limit contacts = end of temperature range

Hysteresis = ±2°C

scanning angle (only IS 12-Al/S): 4°

scanning frequency (only IS 12-Al/S): 5 Hz

Temperature display (°C / °F) = °C

Interface (RS) = RS232

Address (ADR) = 00

Baud rate (kBaud) = 19.2 kBd

Test current output (10 mA) = off

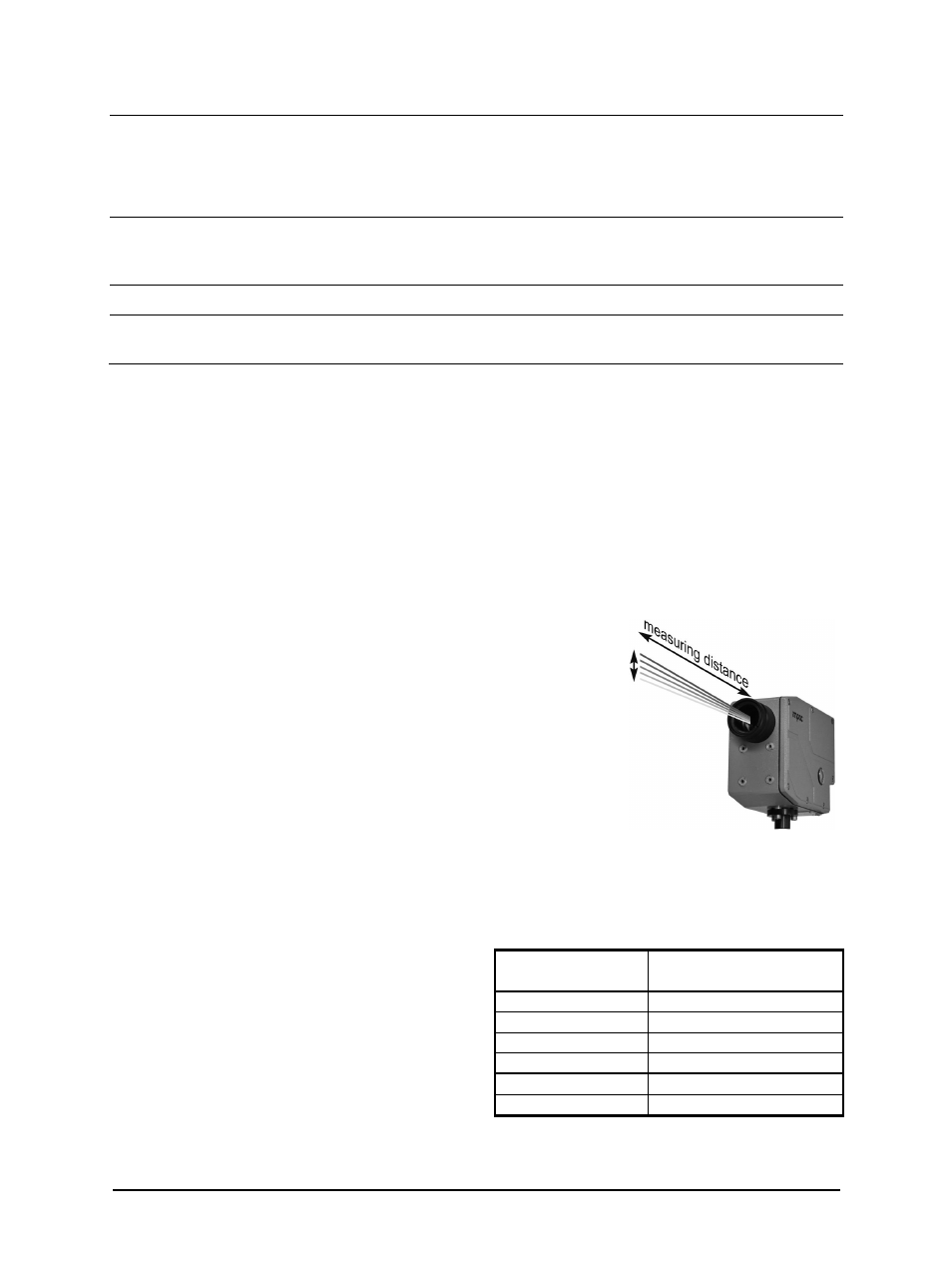

4.4 Types IS 12-Al/S with built-in scanner

4.4.1 Function

The pyrometer IS 12-Al/S is equipped with a built-in

scanning mechanism which moves the measuring beam up

and down. In combination with the pyrometer's maximum

value storage (peak picker) the scanner is used for finding

the highest temperature. This function is very useful for

extrusion applications with frequent changes of dies to

produce different aluminum profiles. In that case, the

pyrometer does not need new alignment after changing

of die.

The instrument is equipped with a thru-lens view finder

and an additional laser targeting light for exact alignment to the position of the measuring

object. The thru-lens view finder doesn’t follow the scanning mirror movement, it always shows

the center of the scanning amplitude. The laser targeting light follows the scanning mirror

movement and shows always the position of the measuring spot.

The moving measuring beam does not increase the spot sizes due to the fast exposure time of

the pyrometers.

The scanning length increases with increasing

measuring distance. An overview of the

scanning length at the different distances of the

optics is shown in the table.

distance a

scanning distance at

4° scanning angle

a = 80 mm

5.6 mm

a = 160 mm

11.2 mm

a = 250 mm

17.5 mm

a = 660 mm

46 mm

a = 1300 mm

91 mm

a = 5600 mm

391 mm

scanning

amplitude