4 transmittance, 5 response time (t90), 4 transmittance t – LumaSense Technologies IGA 6/23 Advanced User Manual

Page 24: 5 response time (t

IGA 6/23 Advanced Manual

Settings / parameter descriptions · 24

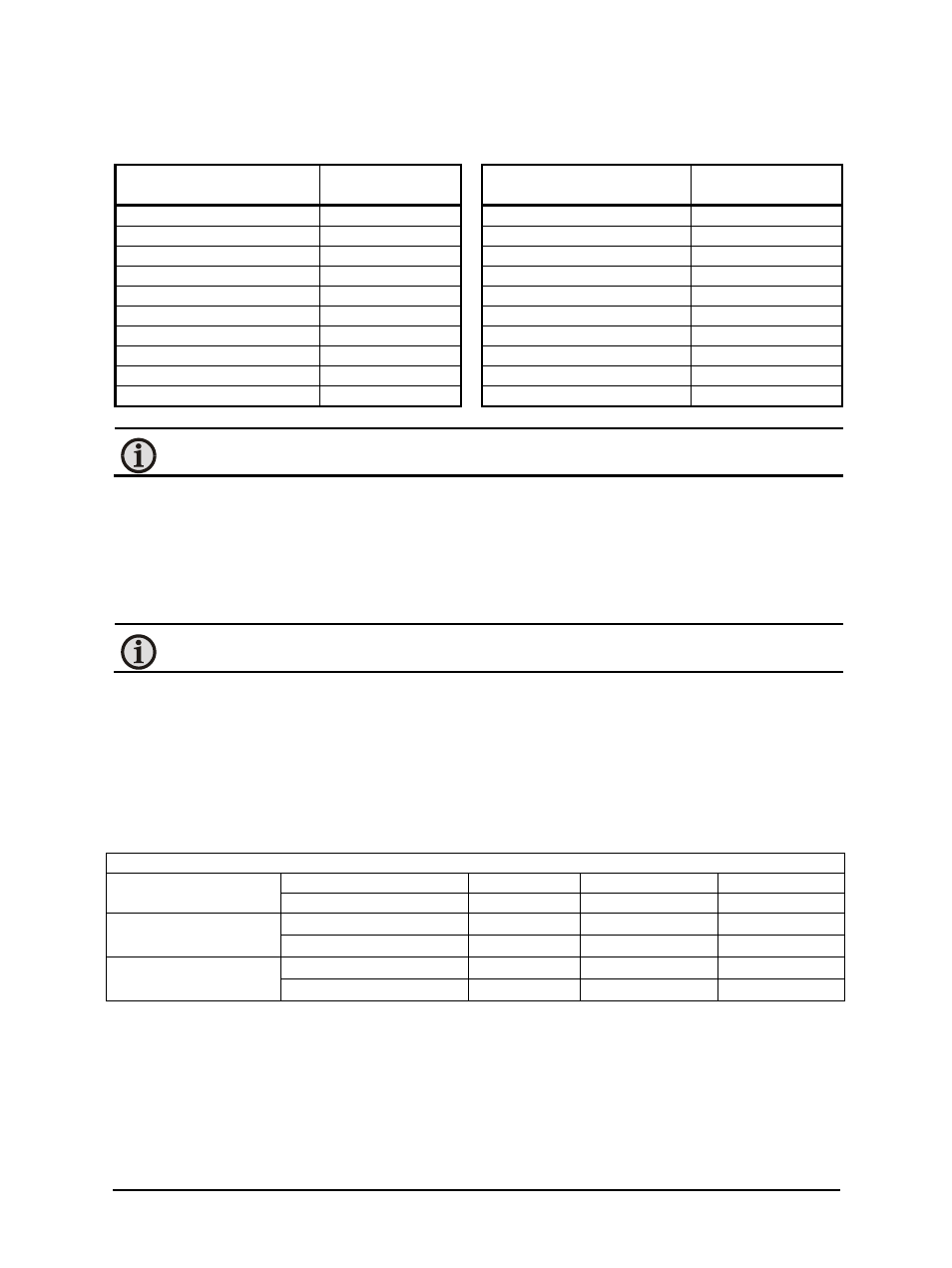

Measuring object

Emissivity [%]

(at 2.3 µm)

Measuring object

Emissivity [%]

(at 2.3 µm)

“Black body furnace“

100

Steel, molten

20 to 30

Extruded Aluminum

13

Nickel

15 to 20

Brass

18

Titanium, non-oxidized

50

Brass oxidized (tarnished)

65 to 70

Titanium, oxidized

75 to 80

Copper

5

Molybdenum

10

Copper, oxidized

70 to 80

Molybdenum, oxidized

75 to 80

Inconel

30

Black Carbon

95

Inconel, oxidized

85

Graphite

80 to 90

Oxidized Iron

85 to 90

Stoneware, glazed

60

Steel rolling scale

80 to 88

Porcelain rough

80 to 90

Note: Emissivity e can be set from 5% to 100% in steps of 0.1%

4.4 Transmittance t

Transmittance is a parameter that can compensate for signal loss due to external windows etc.

For example, if the emissivity of the material is 0.6 and the transmittance of an additional

window is 0.9, then the product would be 0.54 which is well inside the allowed range.

The product of transmittance and emissivity (

t

x

e

) must not be less than 5%

.

Note: Transmittance t can be set from 5% to 100% in steps of 0.1%

4.5 Response Time (t

90

)

The response time t

90

is the time interval for the analog output of the pyrometer to go from a

low temperature value up to 90% of the temperature step to a high value when measuring an

abrupt increase from said low to said high temperature.

The dynamic exposure time adjustment prolongs the exposure time at the lower range limit.

With the InfraWin software and the UPP Data Format commands it is possible to configure the

dynamic exposure time.

Dependency of the response time on the temperature value

MB 10

Temperature value

60 °C

120 °C

150 °C

t

90

min

2 ms

1 ms

0.5 ms

MB 13

Temperature value

100

°C

150

°C

200

°C

t

90

min

2 ms

1 ms

0.5 ms

MB 18

Temperature value

200

°C

250

°C

300

°C

t

90

min

4 ms

1 ms

0.5 ms

Independently of this, the pyrometer performs a measurement every 25 µs and updates the

analog output. Slower response times can be used to achieve a constant temperature reading

for measuring objects that have rapidly fluctuating temperatures.

The response time is set using the InfraWin software or by using the UPP Data Format commands.

When the setting is set to min., the IGA 6/23 Advanced operates using a time constant of