4 pressure measurement sequence (absolute only) – Condec UPC5210 User Manual

Page 9

6

UPC5200/UPC5210 Operation and Maintenance Manual

4. Using the REGULATOR (1), adjust the maximum intensifier pump input pressure, as read by the

REGULATED PRESSURE gauge (6), to 1/10 of the full-scale range of the device-under-test. The unit

utilizes an internal intensifier with a 10:1 ratio. As an example, setting regulated pressure to 300 PSI

would generate an output pressure of 3,000 PSI. Using this technique, the device under test is fully

protected from being accidentally over-pressurized.

5. To generate pressure, enable the

PUMP CONTROL

switch (20) and monitor the pressure as it builds in

the ACCUMULATOR gauge (9). Turn the

PUMP CONTROL

switch (20) off when 10% more than the

target pressure has been achieved.

NOTE: The intensifier PUMP CONTROL switch (20) can be operated in two modes. The up position is

continuous and the down position is momentary/jog.

6. To apply pressure, the

VENT

valve (8) must remain closed. Open the

COARSE ADJUSTMENT

valve (2),

approximately 1/2 turn counter-clockwise, until the numerical display begins to move. In general, the

pressure may be changed rapidly until reaching approximately 90% of the desired final value.

7. Use either the

COARSE ADJUSTMENT

(2) or

VENT

valve (8) to obtain a specific pressure reading. Both

provide precise control. As the pressure approaches the desired value, the valve being used for control

should be rotated slowly clockwise to its closed position. With a little experience, pressure values very

close to the desired final value may be quickly achieved.

NOTE: Use the intensifier PUMP CONTROL switch if the ACCUMULATOR gauge (9) reading falls below

required target pressure value.

8. To obtain exact pressure readings, slowly rotate the

VERNIER

control (13) knob in the direction required

(clockwise to increase pressure) as indicated by the electronic numerical display.

9. Transducer Current Measurement - the current signal from the transducer may be displayed at any time

simply by placing the

DISPLAY SELECT

switch (16) to its CURRENT position.

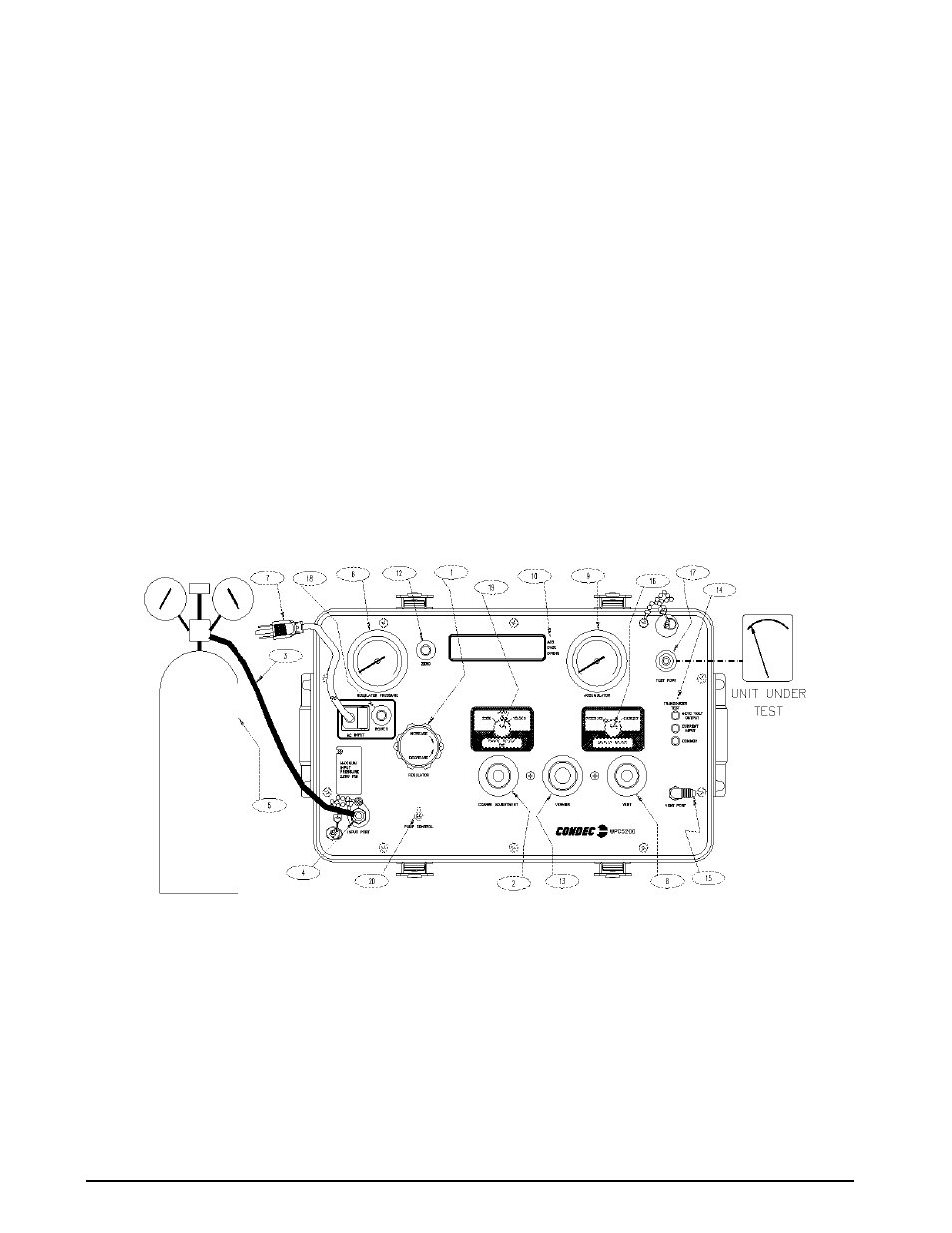

Figure 2-2. Pressure Measurement Sequence (Gage Only)

NOTE: UPC5200 shown, AC Input (7) and Input Port (4) are on back side of UPC5210 Rack Mountable Calibrator.

2.4

Pressure Measurement Sequence (Absolute Only)

NOTE: See Figure 2-3 on page 8, when following these steps.

1. Note that the indicator on the right end of the display indicates ABSOLUTE mode (10).

2. If only pressure measurements greater than barometric are required, continue to step 2.1. If pressure

measurements below atmospheric pressure are required go to step 3.

2.1.

UPC5200: Open the cylinder valve (5) by rotating counter-clockwise slowly until it stops.

UPC5210: Open the pressure source valve (customer supplied).