Condec UPC5210 User Manual

Page 14

Calibration

11

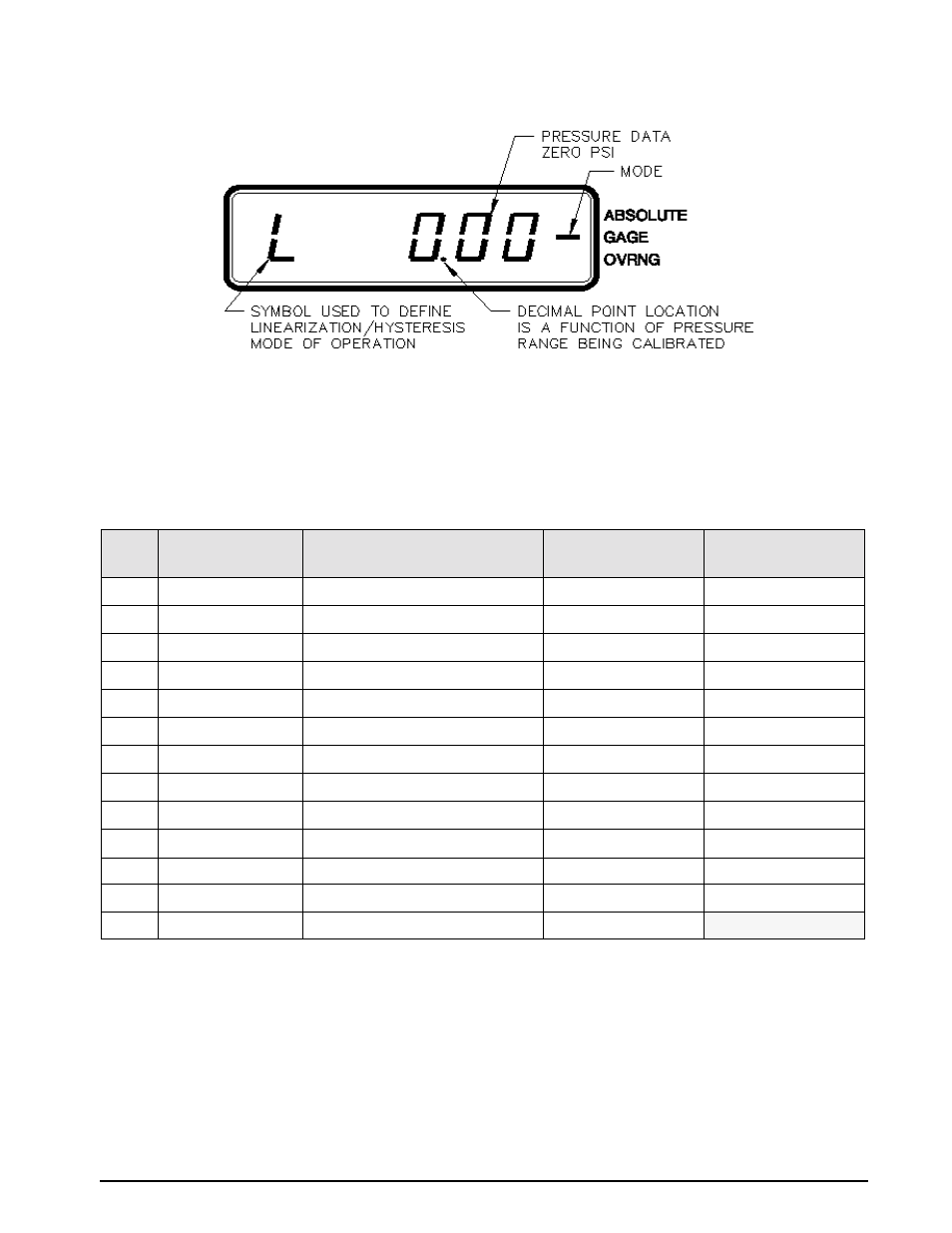

Figure 3-3. Linearity and Hysteresis Calibration

Starting with the instrument's lowest pressure range, sequentially perform the thirteen steps described in

Table 3-2, for each pressure range being calibrated. Perform the following for each step:

1. Adjust input pressure to the appropriate value without overshooting the setting. If value is overshot by

more than 1%, vent unit and repeat steps.

2. Perform the action as indicated when the readings are stable. Should not take longer than 15 minutes. If

it takes longer, check system for leaks. If no leaks are found, the CPU or transducer may be defective.

When step no. 11 is reached, the display changes so that the left most status symbol is

H

. This remains for step 12

and down to approximately 0.00 PSI.

NOTES:

1. If reading is in motion or correction required is not within ±0.8% of Full-Scale, no entry is made.

2. If entry is valid, the display momentarily indicates the correction value (in percent) and the memory location

at which it is stored.

3. If 100% ±0.05% is not obtained, repeat the Zero/Span calibration sequence.

4. Absolute only unit: Maximum PSIA test standard display reading of 0.05 PSIA.

STEP

NO.

INPUT PRESSURE %

OF RANGE

OPERATOR ACTION REQUIRED

STATUS SYMBOL IN

LEFT MOST DIGIT

REMARKS

1

0 (Note 4 below)

Press

ZERO

Switch

L

Zero on Display

2

10

Press

ENTER

button

L

Notes 1 & 2 below

3

20

Press

ENTER

button

L

Notes 1 & 2 below

4

30

Press

ENTER

button

L

Notes 1 & 2 below

5

40

Press

ENTER

button

L

Notes 1 & 2 below

6

50

Press

ENTER

button

L

Notes 1 & 2 below

7

60

Press

ENTER

button

L

Notes 1 & 2 below

8

70

Press

ENTER

button

L

Notes 1 & 2 below

9

80

Press

ENTER

button

L

Notes 1 & 2 below

10

90

Press

ENTER

button

L

Notes 1 & 2 below

11

100

No Action Required

H

Note 3 below

12

50

Press

ENTER

button

H

Notes 1 & 2 below

13

0 (Note 4 below)

No Action Required

L

Table 3-2. Linearization and Hysteresis Calibration Sequence