5 shunt resistor calibration, 6 current input calibration, 7 permanent data storage – Condec UPC5210 User Manual

Page 15

12

UPC5200/UPC5210 Operation and Maintenance Manual

3.5

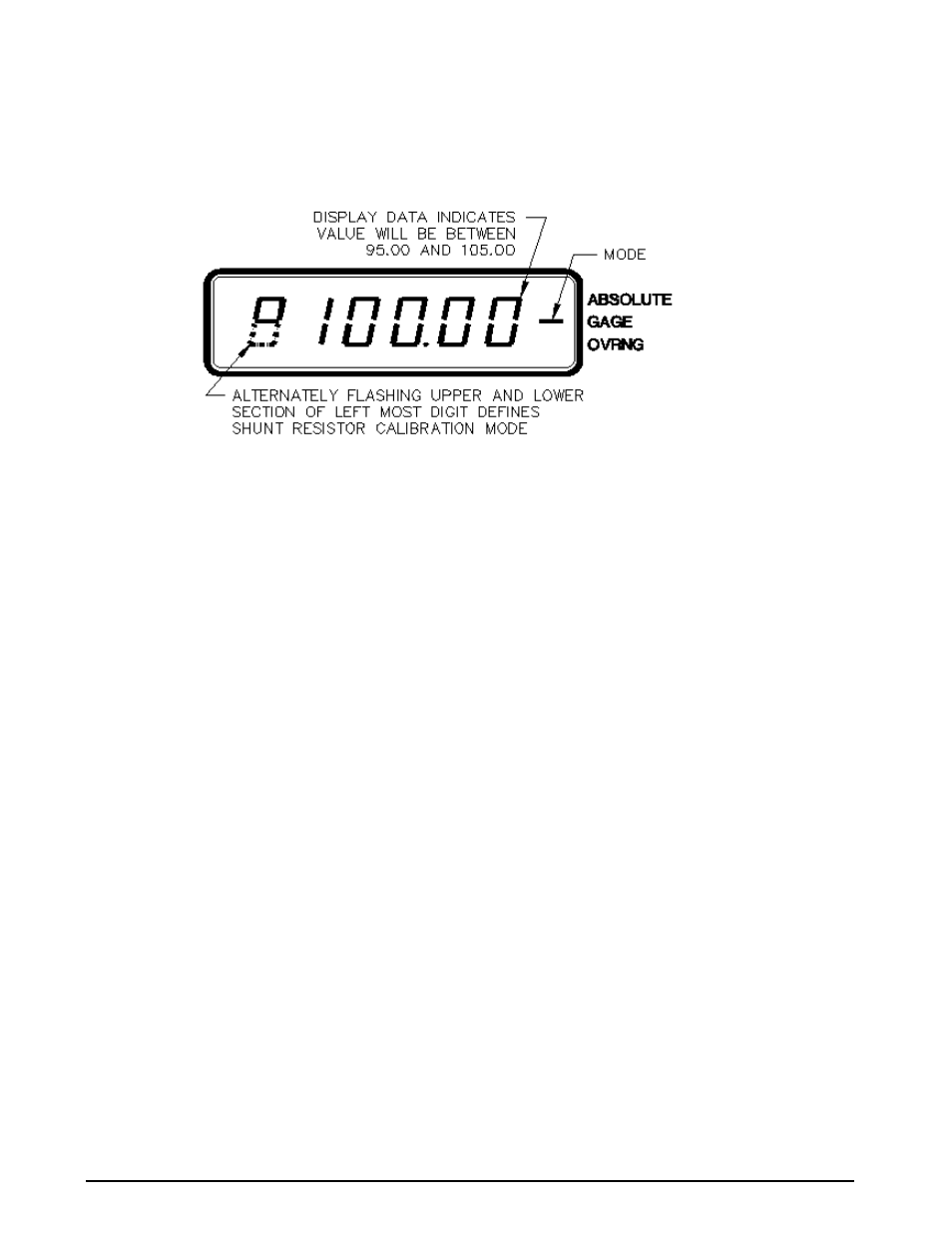

Shunt Resistor Calibration

Install the Condec Calibration Module (PN 60109) and select the SHUNT position of the rotary switch on the

module. This places the UPC5200/UPC5210 into its SHUNT RESISTOR calibration mode. The display is

shown in Figure 3-4.

Figure 3-4. Shunt Resistor Calibration

With the UPC5200/UPC5210's highest pressure range selected, perform the four step sequence described below:

1. Gage Only Units: Be sure the input pressure to the UPC5200/UPC5210 is at 0 PSIG.

NOTE: Absolute Only Units: Must use a vacuum pump with PSIA test standard, to reach as close to 0 PSIA as

possible (maximum PSIA test standard display reading of 0.05 PSIA).

2. Press and hold the

ZERO

button on the Condec Calibration Module until a stable zero indication is

obtained.

3. Release the

ZERO

button and allow the display to stabilize at its shunt resistor calibration number.

(100 ± 5.00%)

4. Press the

ENTER

button on the Condec Calibration Module. When accepted, the bottom half of all

display digits are momentarily illuminated.

3.6

Current Input Calibration

To calibrate the current input, a current generator capable of generating 20 mA must be connected to the

COMMON and CURRENT INPUT jacks, see Figure 2.2 on page 4 (14). The DISPLAY SELECT switch (16)

should be on the CURRENT position.

1. Set the Condec Calibration Module (PN 60109) to the ZERO/SPAN position. The display is similar to

Figure 3-2 on page 10.

2. Press the

ZERO

button on the module. The display reads

0.00

.

3. Set the Current Generator for 20 mA output. Press the

ENTER

button on the module. The display should

read

20.00

.

NOTE: If the display reading is off, set the Current Generator to 0, and press the ENTER button on the Condec

Calibration Module. Set the Current Generator for 20 mA output. The display reads 20.000. If the display

reading is off, press the

ENTER

button on the module. If the display reading is not 20.000, CPU is faulty and

requires servicing.

4. Disconnect the current generator.

3.7

Permanent Data Storage

After completing the above calibration procedures, the new data that has been entered into the computer must be

permanently stored. The sequence to do this is as follows:

1. Select the DATA RECALL position of the rotary switch on the Condec

Calibration Module, (PN 60109).

2. Press the

STORE

pushbutton on the module.

3. If the data is accepted, the four-digit number on the right side of the display indicates

1 020

for as long as

the

STORE

button is pressed.