21 operation – Sterling QVSD User Manual

Page 21

21

OPERATION

Never operate the unit beyond the

specified limits or severe damage to, and/or

premature failure of, the unit will result!

EXPLANATION OF CONTROLS

1. Each Separated Combustion Duct Furnace comes

equipped with a power vent system that consists of a

power ventor motor and blower, pressure switch, and

sealed fl ue collector. (See Figure 15)

The addition of external draft hoods

or power ventors is not permitted. Addition of such

devices may cause serious unit malfunction or

failure.

2. The power ventor is energized by the room thermostat

when a demand for heat is sensed. The pressure

switch measures the differential pressure between

the air inlet and the exhaust vent systems. If the

differential is correct, the indirect spark ignition

system is energized.

Under no circumstances is the

unit to be fi red if the power ventor is not operable,

or severe personal injury or death may occur!

3. The indirect spark ignition system consists of an

ignition module, a dual combination gas valve, and a

spark-ignited pilot burner. When the pressure switch

is closed, the pilot valve opens as a spark is generated

to light the pilot. When the fl ame is sensed by the

fl ame sensing circuit, the spark ceases, and the main

gas valve opens to supply gas to the main burners.

Once the thermostat is satisfi ed, the vent system and

gas valve are simultaneously de-energized, stopping

all gas fl ow to the unit.

4. The high limit switch interrupts the fl ow of electrical

current to the main gas valve if the duct furnace

becomes overheated.

5. The optional fan switch delays the operation of the

fan for approximately 45 seconds once the thermostat

is closed, and continues fan operation for

approximately 65 seconds after the thermostat opens.

The start-up fan delay must not exceed 90 seconds

from a cold start.

6. The wall thermostat, supplied optionally, is a

temperature sensitive switch that operates the vent

and ignition systems to control the temperature of

the space being heated.

NOTICE: The thermostat must be mounted on a

vertical, vibration-free surface, free from air currents,

and in accordance with the furnished instructions.

INITIAL LIGHTING

1. Open the manual gas valve, in the gas supply line to

the duct furnace. Loosen the union in the gas supply

line to purge it of air. Tighten the union, and check for

leaks.

NOTICE: Check all pipe joints for leakage using a soap

solution or other approved method.

Never use an open fl ame to detect

gas leaks. Explosive conditions may exist which

could result in property damage, personal injury

or death.

Before attempting to light or

relight the pilot, wait 5 minutes to allow gas

which may have accumulated in the burner

compartment to escape. Failure to heed this

warning could result in property damage,

personal injury or death!

2. Turn on electrical power. The duct furnace should now

be under the control of the thermostat. Set the

thermostat to it's highest setting, the power ventor

motor should start, and burner ignition occur. Turn

the thermostat to the lowest setting. The burners and

power ventor should stop operating immediately.

Reset the thermostat to the desired operational

setting.

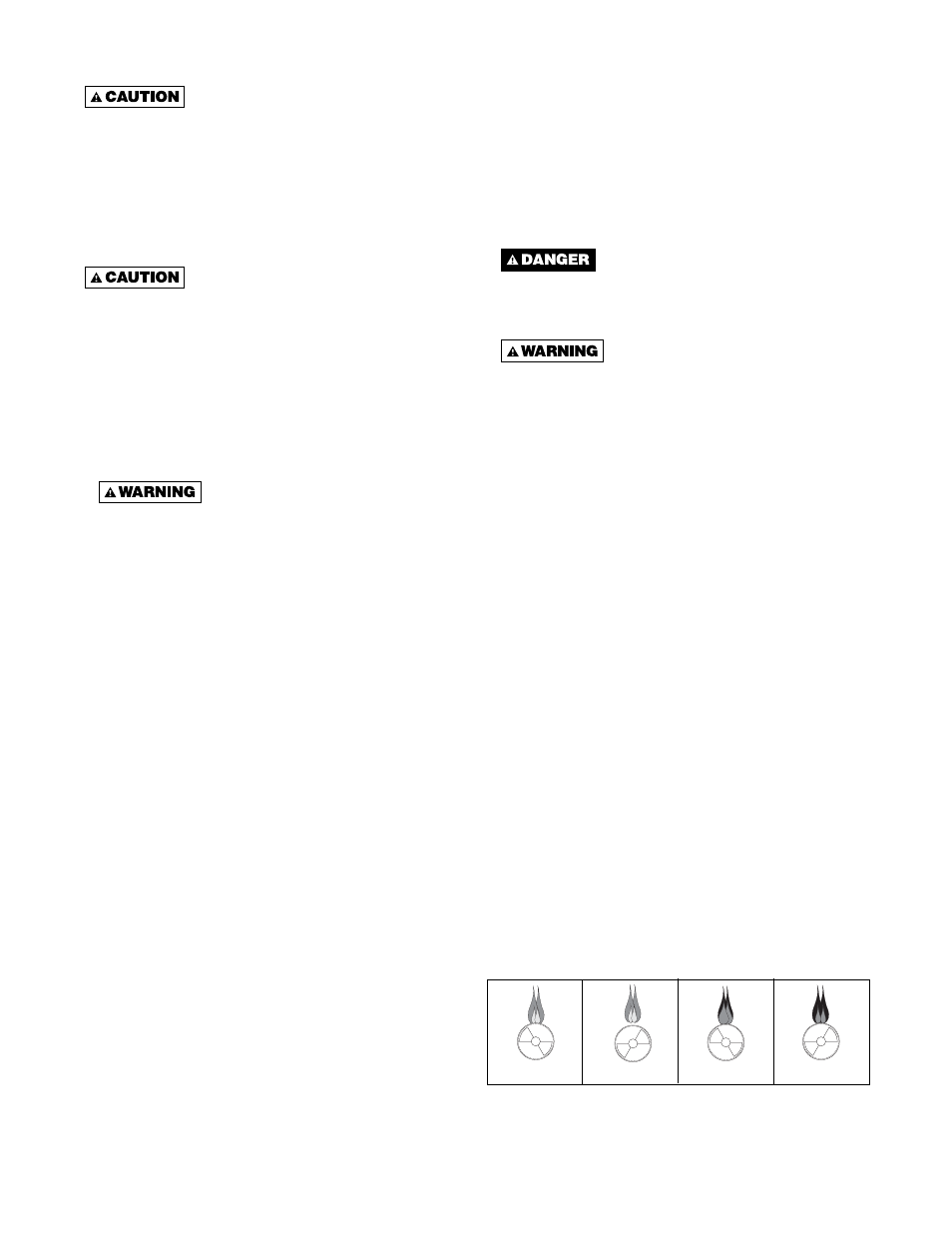

PRIMARY AIR SHUTTER ADJUSTMENT

After the unit has been operating for at least 15 minutes,

adjust the primary air flow to the burners. Turn the

friction-locked, manually-rotated air shutters clockwise to

close, and counterclockwise to open.

For correct air adjustment, close the shutter until yellow

tips in the fl ame appear. Then, open the air shutter to the

point just beyond where the yellow tipping disappears.

Refer to Figure 12.

NOTICE: There may be momentary and spasmodic

orange fl ashes in the fl ame. This is caused by the

burning of airborne dust particles, and should not

be confused with yellow tipping, which is a stable, or

permanent, situation when there is insufficient

primary air.

Figure 12 - Main Burner Flames

SHUT DOWN

1. Turn the valve selector knob to the "OFF" position.

2. Turn off the electricity.

3. To relight, follow "Initial Lighting" instructions.

NORMAL

(HARD FLAME)

LIFTING

(TOO MUCH AIR)

YELLOW TIPPING

(MARGINAL)

YELLOW FLAME

(TOO LITTLE AIR)