Sterling TD User Manual

Page 7

7

INSTALLATION (continued)

DUCTWORK

Properly designed and installed ductwork, providing a

uniformly distributed fl ow of air across all surfaces of the

heat exchanger, is essential to satisfactor y unit

performance and life of the equipment.

All duct connection fl anges/seams must be sealed to

prevent air leaks. Sealant/tape must be suitable for

temperatures of 250°F (121°C) minimum.

Any attempts to straighten the 90°

duct connection fl anges on the duct furnaces will

affect the operation of the furnace and will void

the warranty.

If uniform air distribution is not obtained, install additional

baffl es and/or turning vanes in the ductwork.

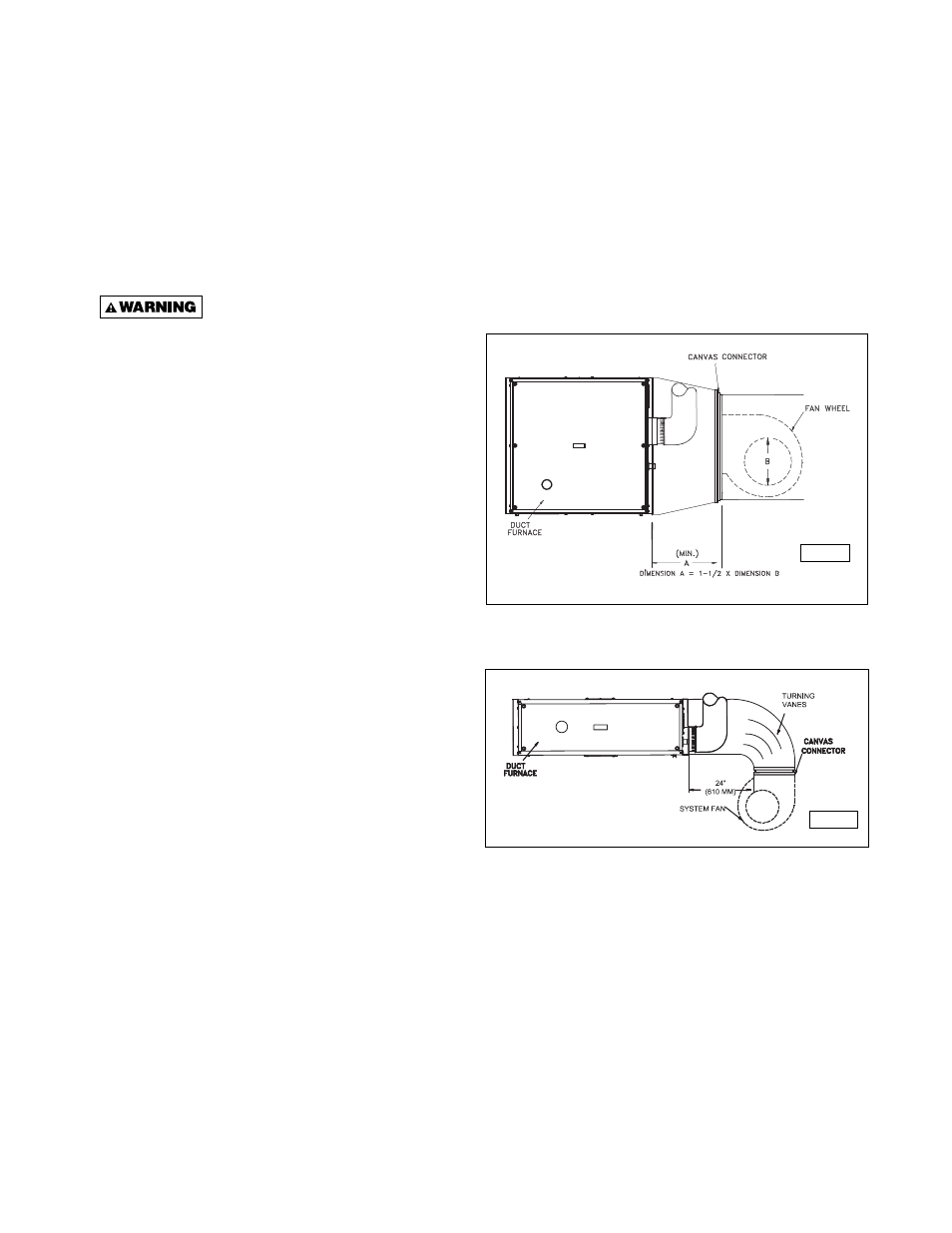

Figures 3 and 4 illustrate recommended ductwork designs

for both the straight-through and elbowed air inlet

arrangements.

Access panels large enough to observe smoke and

refl ected light, and to detect the presence of leaks in the

heating equipment, are required both upstream and

downstream from gas duct furnaces. These panels must

be sealed to prevent air leaks. If allowed by local

regulations, install canvas connectors between the

ductwork and fan discharge opening to eliminate the

transmission of mechanical vibration.

AIR FLOW

The installation is to be adjusted to obtain an air

throughput within the range specifi ed on the appliance

rating plate.

COMBUSTION INLET AIR VENTILATION

Inlet Air From Another Room – If the duct furnace is

installed in a separate room or compartment, provide two

inlet air openings. The size of each vent opening should

be no less than one square inch (6.452 square centimeters)

of free area for each 1000 Btu/hr. (293 W) input. Each

opening must not be less than 100 square inches (645

square centimeters).

Inlet Air From Outdoors – If the enclosed space is

to have inlet combustion air from the outside, the vent

opening should be no less than one square inch

(6.452 square centimeters) of free area for each

2500-3000 Btu/hr. (733-879 W) input. Each opening must

not be less than 100 square inches (645 square

centimeters).

BYPASS

When a gas duct furnace is installed to operate in

conjunction with a summer air conditioning system, the

CFM air delivery of the system blower should be adjusted

to meet the design air volume requirements for cooling.

If this CFM delivery is greater than that required for

heating, resulting in a low air temperature rise, install a

damper bypass around the gas duct furnace to bypass a

portion of the air.

Figure 3 - Recommended Ductwork Design for

Straight-Through Arrangement

Figure 4 - Recommended Ductwork Design

for Elbowed Arrangement

D9382

D9381