Sterling TD User Manual

Page 25

25

OPERATION

TUBULAR DUCT FURNACE DIRECT SPARK IGNITION

EXPLANATION OF CONTROLS:

1. The duct furnace is equipped with a power vent

system that consists of a power vent motor and

blower, pressure switch, and sealed fl ue collector in

place of a conventional gravity vent draft diverter.

2. The power vent motor is energized by the room

thermostat through the integrated control board when

a demand for heat is sensed. The pressure switch

measures the flow through the vent system and

energizes the direct spark ignition system, beginning

the pre-purge timing when the fl ow is correct.

The pressure switch MUST NOT be

bypassed. The duct furnace MUST NOT be fi red

unless the power vent system is operating. An

unsafe condition could result.

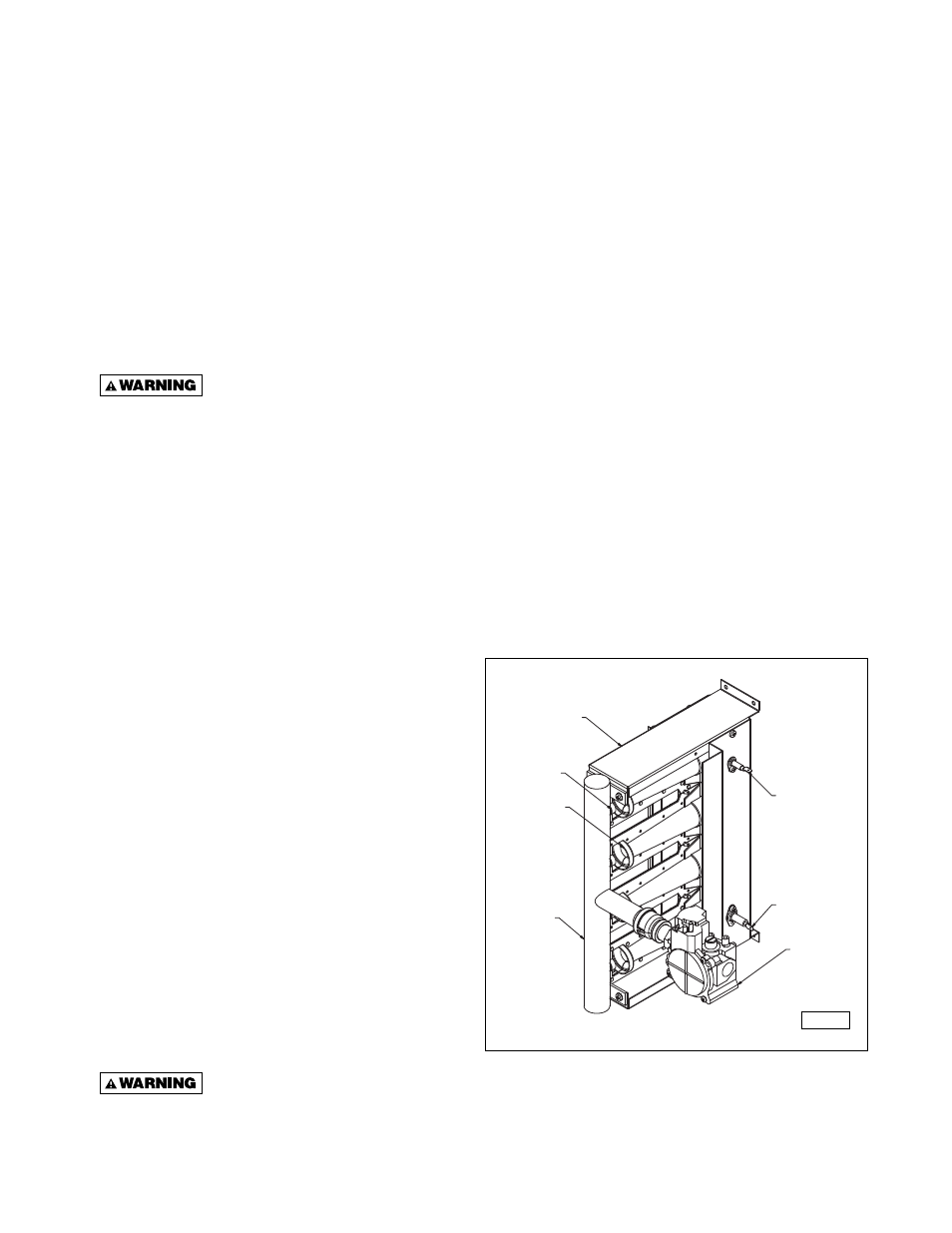

3. The direct spark ignition system consists of an

integrated control board, a spark ignitor, a fl ame

sensor, and a gas valve. When the pre-purge period

ends, the direct spark ignition system is energized,

and the gas valve opens to supply gas to the burners.

When the thermostat is satisfi ed, the vent system is

de-energized and the gas valve closes to stop the

fl ow of gas to the unit. (See Figure 12.)

4. The high limit switch interrupts the fl ow of electric

current to the control board if the duct furnace

becomes overheated, interrupting the fl ow of gas to

the gas valve. The duct furnace will begin a post-

purge period. When the post-purge period ends, the

power vent motor is de-energized.

5. Once the thermostat is satisfi ed, the duct furnace will

begin a post-purge period. When the post-purge

period ends, the power vent motor is de-energized.

6. The wall thermostat, supplied optionally, is a

temperature sensitive switch that operates the power

vent and direct spark ignition system to control the

temperature of the space being heated.The thermostat

must be mounted on a vertical, vibration-free surface

free of air currents and in accordance with the

furnished instructions (also refer to Electrical

Connections section of this manual).

START-UP (Also refer to lighting instruction plate

equipped on the unit)

1. Open the manual gas valve in the gas supply line to

the duct furnace. Loosen the union in the gas line to

purge it of air. Tighten the union and check for leaks.

Never use an open fl ame to detect

gas leaks. Explosive conditions may exist which

could result in personal injury or death.

2. Open the supply gas valve on the duct furnace.

3. Turn ON the electrical power.

4. Turn on system fan (provided by others).

NOTICE: Failure to turn on system fan when duct

furnace is running will cause the unit to trip on high

limit. This may result in damage to the duct furnace

and heat exchanger.

5. The unit should be under the control of the thermostat.

Turn the thermostat to the highest point and

determine that the power vent motor starts and the

burners ignite. Turn the thermostat to the lowest point

and determine that the power vent motor shuts off

and the burners are extinguished.

6. Turn the thermostat to the desired position.

7. See Gas Input Rate section.

SHUT DOWN

1. Turn the supply gas valve selector to the OFF position.

2. Turn off the electricity.

3. To relight, follow “START-UP” instructions.

See Figures 12 and 13 for parts identifi cation.

Figure 12 - Direct Spark Ignition System,

Tubular Duct Furnace

ORIFICE

BURNER BRACKET

D9375

GAS VALVE

SPARK IGNITOR

FLAME SENSOR

BURNER

MANIFOLD

D9375