Installation (continued) – Sterling TD User Manual

Page 11

11

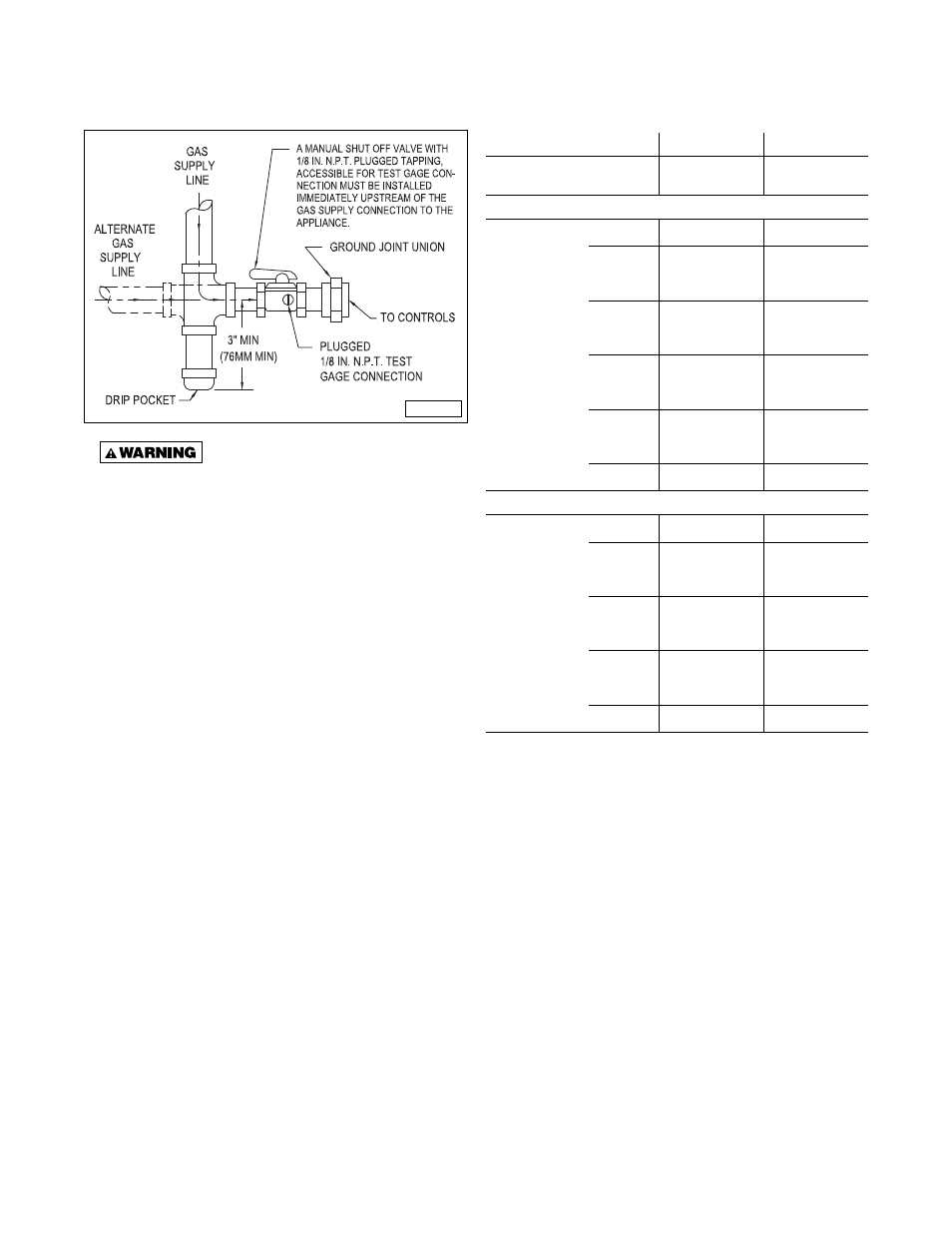

INSTALLATION (continued)

Figure 6 - Pipe Installation, Standard Controls

Never use an open fl ame to detect

gas leaks. Explosive conditions may exist which

may result in personal injury or death!

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system in excess of 1/2 psig

(3.5 kPa).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig

(3.5 kPa).

Table 5 - Gas Supply Pressure*

Natural Gas

Propane Gas

Heating Value

1,050 BTU/Ft

3

(39.1 MJ/m

3

)

2,500 BTU/Ft

3

(93.1 MJ/m

3

)

Manifold Pressure

Single Stage

Application

(inch WC)

(kPa)

3.5

(0.87)

10.0

(2.49)

Two Stage

Application -

High Fire

(inch WC)

(kPa)

3.5

(0.87)

10.0

(2.49)

Two Stage

Application -

Low Fire

(inch WC)

(kPa)

1.1

(0.27)

3.8

(0.95)

Modulating

Application -

High Fire

(inch WC)

(kPa)

3.5

(0.87)

10.0

(2.49)

Modulating

Application -

Low Fire

(inch WC)

(kPa)

0.9

(0.22)

3.5

(0.87)

Minimum Supply Pressure

Single Stage

Application

(inch WC)

(kPa)

5.0

(1.24)

11.0

(2.74)

Two Stage

Application

(inch WC)

(kPa)

6.5

(1.62)

11.5

(2.86)

Modulating

Application

(inch WC)

(kPa)

6.5

(1.62)

11.5

(2.86)

Maximum

Supply

Pressure

(inch WC)

(kPa)

14.0

(3.49)

14.0

(3.49)

* Applicable for units installed at or below 2,000 feet (610m) altitude.

See High Altitude Deration information for altitudes greater than

2,000 feet (610m).

D3631C