Sterling TD User Manual

Page 30

30

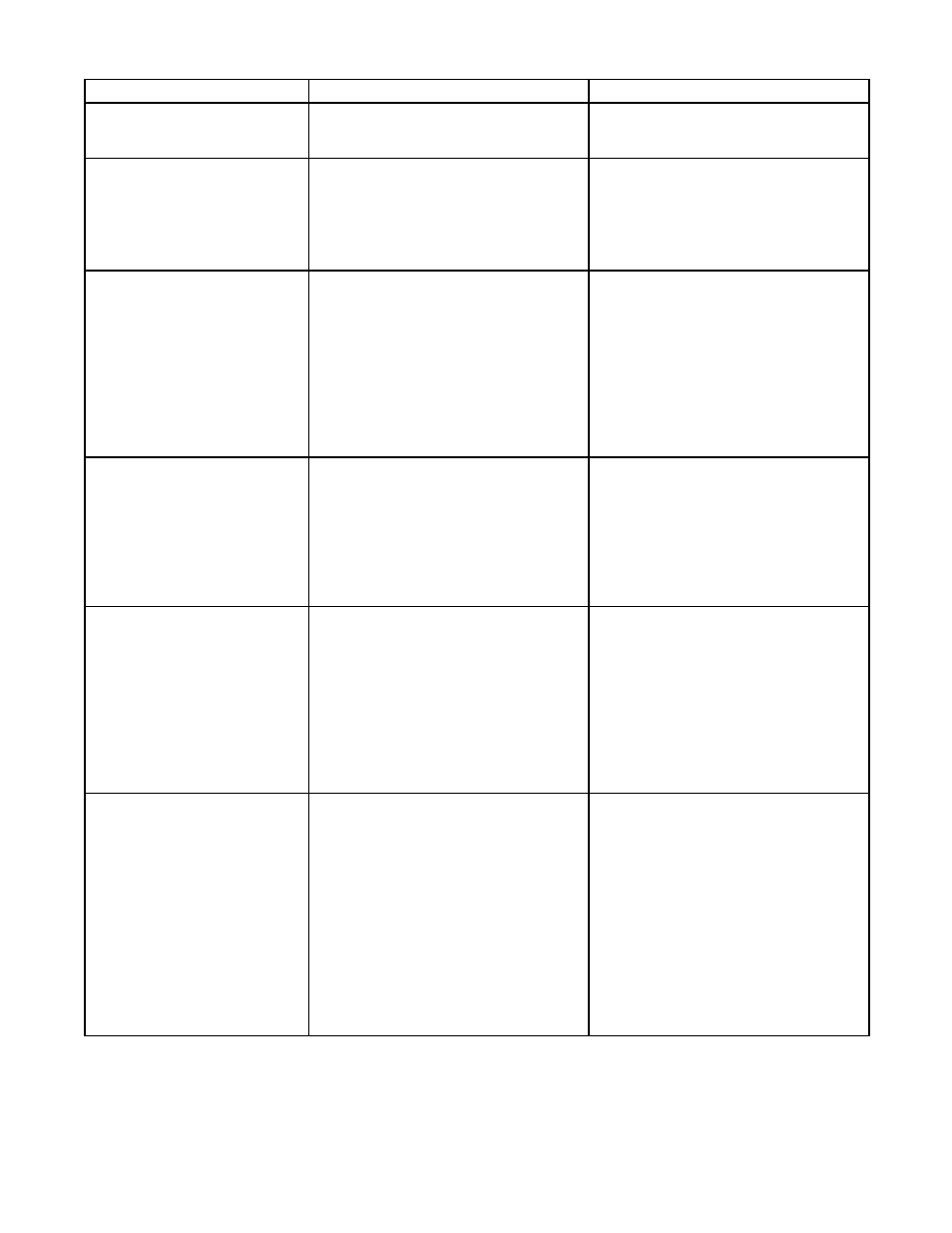

SYMPTOMS

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Table 8A – Tubular Duct Furnace Troubleshooting Guide

A. Flame pops back.

B. Noisy

fl

ame.

C. Yellow tip fl ame.

Note: Some yellow tipping

on LP gas is permissible.

D. Floating

fl

ame.

E. Gas

odor.

Shut off gas supply

immediately!

F. Delayed

ignition.

1. Burner orifi ce too small.

1. Irregular orifi ce causing whistle

or

resonance.

2. Excessive gas input.

1. Clogged main burners.

2. Misaligned

orifi

ces.

3. Insuffi cient combustion air.

4. Unit possibly over fi red.

5. Partially blocked fl ue vent pipe.

1. Blocked

venting.

2. Insuffi cient combustion air.

3. Blocked heat exchanger.

4. Air leak into combustion chamber or

fl

ue

collector.

1. Gas

leak.

Shut off gas supply

immediately!

2. Leaking gas test port on valve.

3. Blocked heat exchanger.

4. Blocked fl ue collector.

5. Negative pressure in the building.

1. Improper

ground.

2. Bad or broken spark cable.

3. Faulty control board.

4. Pressure regulator set too low.

5. Main burner orifi ces dirty.

6. Improper

venting.

1. Check with local gas supplier for proper

orifi ce size and replace. Refer to “Gas

Input Rate” section of this manual.

1. Replace

orifi

ce.

2. Test and reset manifold pressure (see

“Gas Supply Pressure” Table in

the Pipe Installation section of this

manual.)

1. Clean main burner ports.

2. Replace manifold assembly.

3. Refer to “Installation - Clearances”

and “Venting” sections in this manual

to ensure unit is properly mounted

and

vented.

4. Check gas input and manifold

pressures.

5. Check fl ue vent pipe and clear as

needed.

1. Check fl ue vent pipe and clear as

needed.

2. Check combustion air inlet openings

and/or vent pipe and clear as needed.

3. Clean heat exchanger. Refer to

“Maintenance” section of this manual.

4. Check fl ue collector and clear as

needed.

1. Inspect all gas piping and repair

accordingly.

2. Check to ensure gas test ports are

sealed.

3. Clean heat exchanger. Refer to

“Maintenance” section of this manual.

4. Check fl ue collector and clear as

needed.

5. See “Installation” section of this

manual.

1. Check grounding wires and spark

ignitor

connections.

2. Inspect spark cable connections and

cuts. Replace if necessary.

3. Check to ensure spark ignitor is

energized after pre-purge period.

4. Test and reset manifold pressure (see

“Gas Supply Pressure” Table in

the Pipe Installation section of this

manual.)

5. Clean or replace orifi ces.

6. Refer to “Venting” section of this

manual.