Sterling TD User Manual

Page 32

32

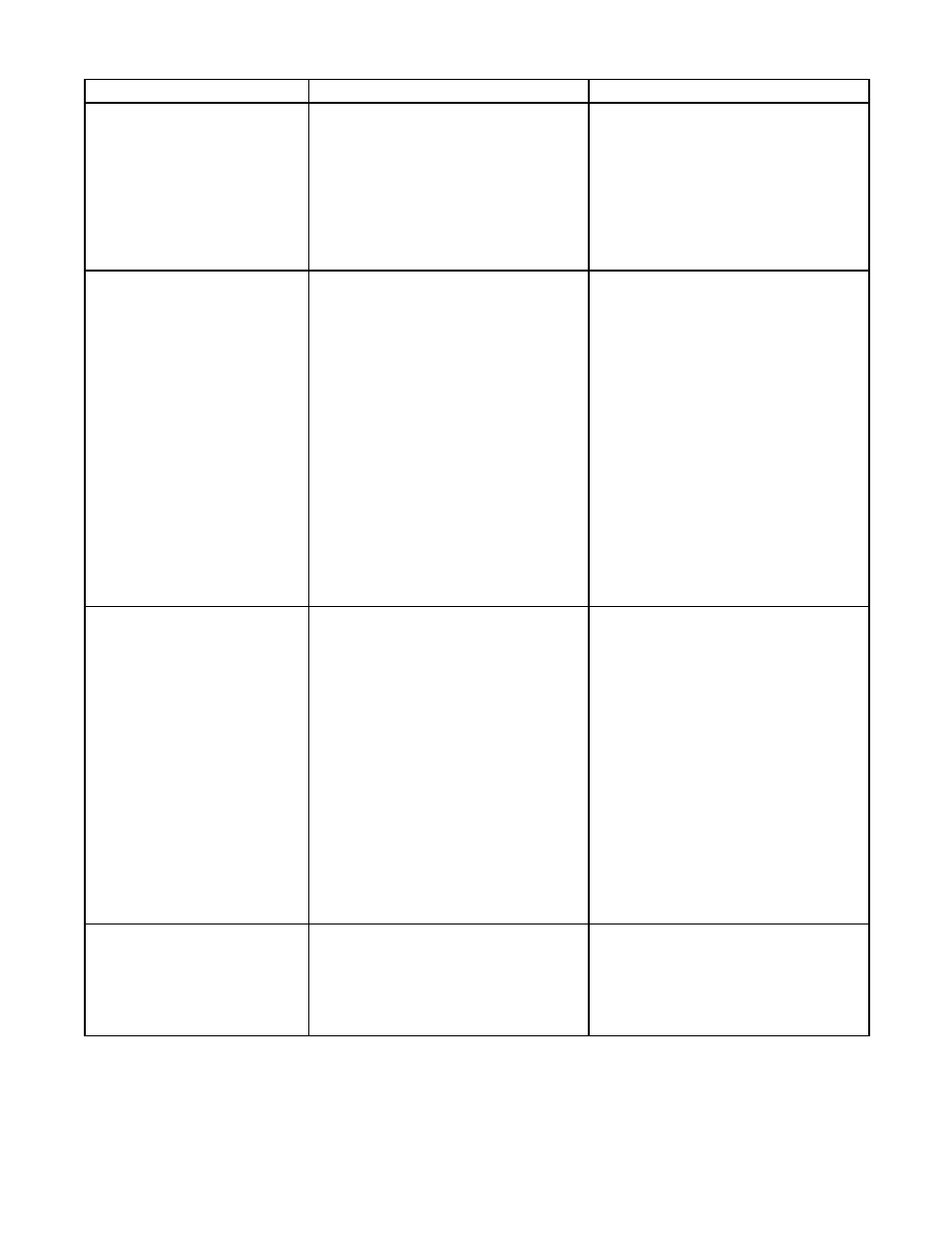

SYMPTOMS

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

1. Tighten all electrical connections.

2. Check for proper air supply across

heat exchanger and proper gas supply.

3. Relocate thermostat away from outside

wall or drafts.

4. Jumper high limit switch wiring (orange

and yellow wires). If burner operating

normally, replace switch.

1. Refer to “Gas Input Rate” in the

Operation section of this manual.

2. Is the unit output sized correctly for

the heat loss of the space? Has the

space been enlarged? Is the unit

located in the space properly (see

“Installation” section of this manual)?

3. Check thermostat circuit; 24V on

terminals “R” and “W” on terminal strip.

4. Check air movement across the heat

exchanger. Check gas input to ensure

unit is not over fi red. Check heat

exchanger to ensure unit is not dirty.

5. Check orifi ce size (refer to “Gas

Input Rate” in the Operation section

of this manual).

6. See blower manufacturer for

corrective

action(s).

1. Refer to “Gas Input Rate” in the

Operation section of this manual.

Check orifi ce size. Replace if too large.

2. Check thermostat for operation, to

ensure circuit open and closes.

3. Check wiring per diagram. Check

operation at the gas valve. Look for

a short in thermostat circuit.

4. Replace valve and check pressure

setting (see “Gas Supply Pressure”

Table in the Pipe Installation section

of this manual).

5. Refer to “Gas Supply Pressure” Table

in the Pipe Installation section of this

manual.

6. See blower manufacturer for

corrective

action(s).

1. Test and reset manifold pressure

(see “Gas Supply Pressure” Table

in the Pipe Installation section of this

manual.)

2. See blower manufacturer for

corrective

action(s).

1. Loose electrical connections at

thermostat or gas valve.

2. Unit cycling on high limit.

3. Thermostat located improperly.

4. Defective high limit switch.

1. Incorrect gas input.

2. Unit

undersized.

3. Thermostat

malfunction.

4. Unit cycling on high limit.

5. Incorrect orifi ce sizes.

6. Incorrect

airfl

ow.

1. Unit is over fi red.

2. Thermostat

malfunction.

3. Unit runs continuously.

4. Defective gas valve.

5. Excessive gas supply pressure.

6. Incorrect

airfl

ow.

1. Incorrect manifold pressure or

gas

input.

2. Incorrect

airfl

ow.

J. Rapid burner cycling.

K. Not enough heat.

L. Too much heat.

M. Cold air is delivered during

heater

operation.

Table 8A – Tubular Duct Furnace Troubleshooting Guide (continued)