Introduction and general description, 1. instrument check, 2. application – Yokogawa EXAxt PH450 4-Wire Analyzer for pH and ORP User Manual

Page 9

1

IM 12B07C05-01E

1

INTRODUCTION

AND

GENERAL

DESCRIPTION

The Yokogawa EXAxt PH450G is a converter

designed for industrial process monitoring, meas-

urement and control applications. This instruction

manual contains the information needed to install,

set up, operate and maintain the unit correctly.

This manual also includes a basic troubleshooting

guide to answer typical user questions.

Yokogawa can not be responsible for the

performance of the EXAxt converter if these

instructions are not followed.

1-1. Instrument check

Upon delivery, unpack the instrument care-

fully and inspect it to ensure that it was not

damaged during shipment. If damage is found,

retain the original packing materials (including

the outer box) and then immediately notify the

carrier and the relevant Yokogawa sales office.

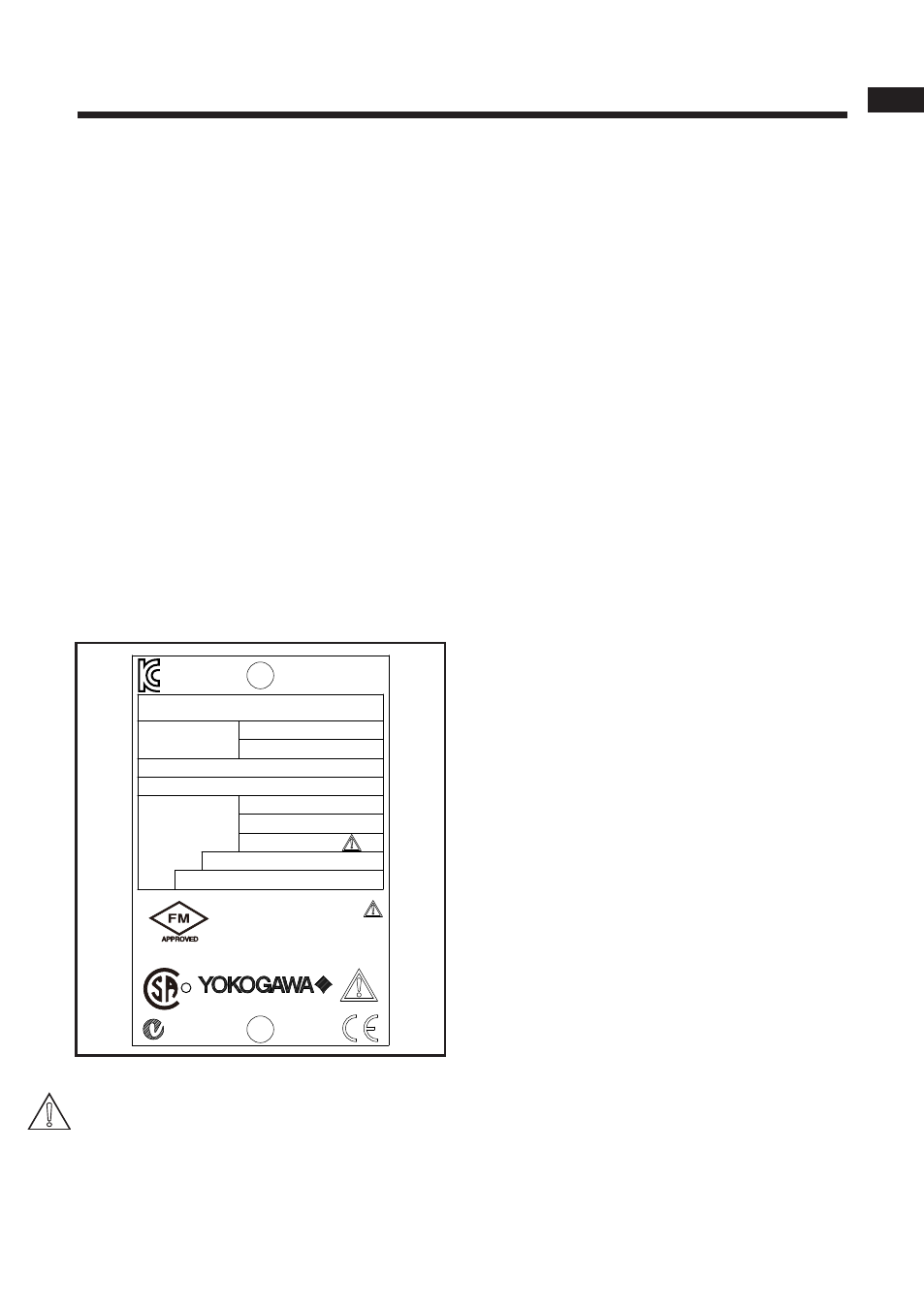

Make sure the model number on the nameplate

affixed to the side of the instrument agrees with your

order. Example of the nameplate is shown below.

C

US

STYLE

Made in Japan

N200

-20 to +55

°C

4-20mA(mA1: +HART)

NO.

AMB. TEMP.

OUTPUTS

SUPPLY

SUFFIX

MODEL

NI CL I, DIV 2, GROUPS ABCD

T6 FOR Ta -20 to +55°C

R

PH450G

PH/ORP TRANSMITTER

SEE INSTRUCTION MANUAL

TYPE 4X

SEE CONTROL DRAWING

NFM016-A9 P.1

KCC-REM-

YHQ-EEN257

Figure 1-1. Nameplate

Note! The nameplate will also contain

the serial number and any relevant

certification marks. Be sure to apply

correct power to the unit, as detailed

on the nameplate.

1-2. Application

The EXAxt converter is intended to be used

for continuous on-line measurement of pH

and/or Redox in industrial installations. The

unit combines simple operation and micro-

processor-based performance with advanced

self-diagnostics and enhanced communications

capability to meet the most advanced require-

ments. The measurement can be used as part

of an automated process control system. It can

also be used to indicate operating limits of a

process, to monitor product quality, or to func-

tion as a controller for a dosing/neutralisation

system.

Sensors should normally be mounted close to

the converter in order to ensure easy calibra-

tion and peak performance. If the unit must

be mounted remotely from the sensors, WF10

extension cable can be used, up to a maximum

of 60 meters (150 feet), with a BA10 junction

box, and up 10 meters standard sensor cable.

The EXAxt is delivered with a general purpose

default setting for programmable items (see

Chapter 5). While this initial configuration

allows easy start-up, the configuration should

be adjusted to suit each particular application.

An example of an adjustable item is the type

of temperature sensor used. The EXAxt can

be adjusted for a number of different types of

temperature sensors.

Details provided in this instruction manual

are sufficient to operate the EXAxt with all

Yokogawa sensor systems and a wide range

of third-party commercially available probes.

For best results, read this manual in conjunc-

tion with the corresponding sensor instruction

manual.

Yokogawa designed the EXAxt converter to

withstand industrial environments. It meets all

the CE regulatory standards. The unit meets or

exceeds stringent requirements (see section

2) without compromise, to assure the user of

continued accurate performance in even the

most demanding industrial installations.

1. INTRODUCTION AND GENERAL DESCRIPTION