3-4. slope – Yokogawa EXAxt PH450 4-Wire Analyzer for pH and ORP User Manual

Page 28

20

IM 12B07C05-01E

of the sensor (default 7.00 pH). The ZERO

value indicates the condition of the sensor. If

the value exceeds +/- 120 mV (or user defined

limits) an error message is displayed after

calibration and the calibration is rejected. The

trend of ZERO drift during the lifetime of the

sensor is used to predict the lifetime of the

sensor.

ZERO can also be displayed in pH units and

then it represents the pH value where the

sensor output is 0 mV at 25 ºC. Go to:

Com-

missioning >> Measurement >> Calibration

Settings >> Zero and Slope Units

4-3-4. Slope

= calibrated efficiency of the sensor unit in

percentage of theoretical slope of the sensor

unit. The theoretical slope follows the NERNST

equation and is 59.16 mV/pH. The SLOPE can

be calibrated only after a two-point calibration

in buffer solutions with a different pH value. A

low slope indicates that the sensor is not clean

or it indicates a bad sensor. If the calibrated

slope exceeds the range 70-110% (or user

defined limits) then the calibration is rejected

and a error message is shown.

The SLOPE can also be displayed as mV/pH

value at 25 ºC if the user has defined this

variable as mV/pH in

Commissioning >>

Measurement >> Calibration Settings >>

Zero and Slope Units

4-3-5. Sensor mV

= the output of the sensor unit prior to calibra-

tion and temperature compensation. This value

is important for trouble shooting.

4-3-6. Reference impedance

= the electrical resistance of the liquid junc-

tion. The liquid junction forms the electolytical

contact between the reference element and

the measuring electrode, so it must be kept

clean and filled with conductive electrolyte.

Otherwise the measurement will suffer from

instability, drift and measuring errors. The elec-

trical impedance is one of the most important

diagnostic tools for keeping the measurement

in good condition. If the value exceeds a user

defined limit (1000Ω - 1000kΩ) an error mes-

sage will be displayed.

4-3-7. Last calibrated

= the date on which the last sensor calibra-

tion is done. The displayed value of the ZERO

is the result of this calibration. The displayed

value of Slope is not necessarily calibrated

on this date: only if the last calibration was a

2-point calibration.

4-3-8. Calibration due

= the date when the calibration must be done

according to the settings of the maintenance

timer. This is based on scheduled maintenance

procedures. The maintenance intervals are

set in menu:

setup>> Commissioning>>

measurement setup>> calibration settings

>> limits and timing

4-3-9. Projected calibration

= the date when the predictive maintenance

function expects that recalibration of the sen-

sor unit is necessary for good measurement

accuracy. The converter checks the reference

impedance every hour. The user is notified

when maintenance should take place. Prior to

calibration the sensor should be well cleaned

and rinsed.

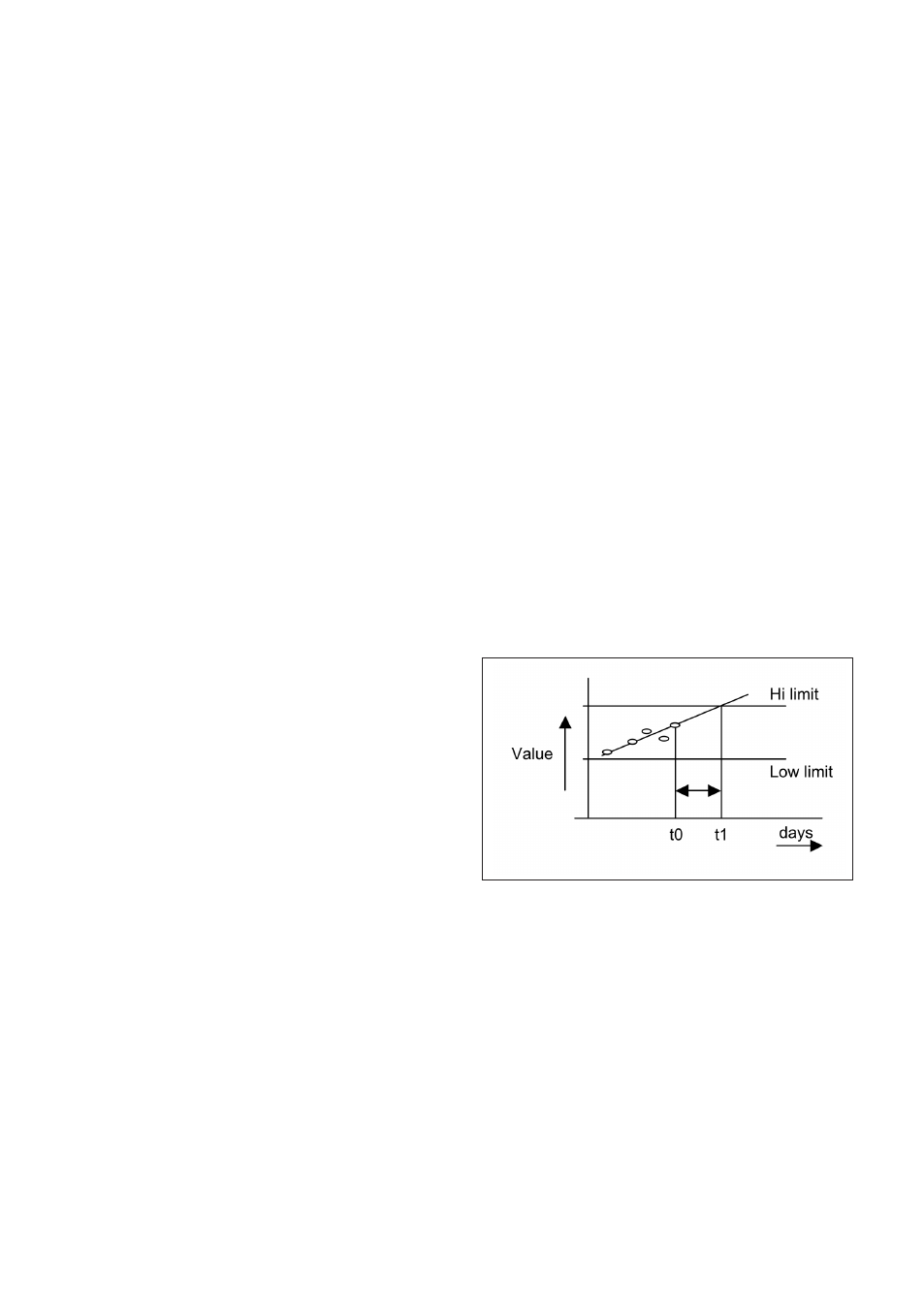

4-3-10. Projected replacement

= the date when the predictive maintenance

function expects that replacement of the

sensor is necessary for good measurement

accuracy. After each calibration the slope, zero

and reference impedance are logged. Aging

of the sensor can be detected from this data.

The observed trend is extrapolated and the

trend predicts when max deviations will be

exceeded. Good predictions are only achieved

with good calibration data. Prior to calibration

the sensor should always be well cleaned and

rinsed and the calibration procedures strictly

observed.