5. calibration settings, 6. impedance setting – Yokogawa EXAxt PH450 4-Wire Analyzer for pH and ORP User Manual

Page 34

26

IM 12B07C05-01E

5-5. Calibration settings

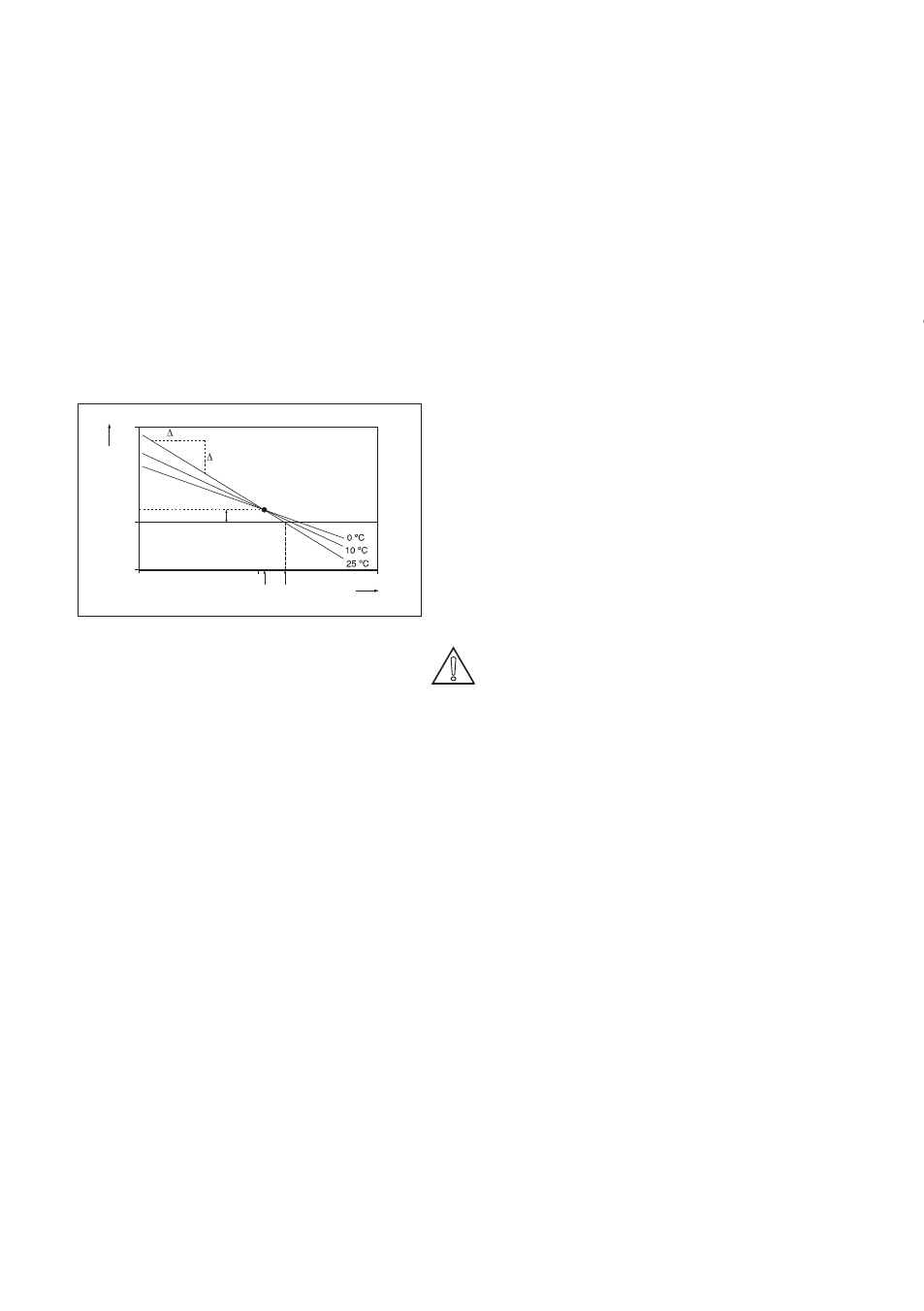

Calibration settings for a pH converter involve

slope (sensitivity), zero (aspot) and ITP (iso

thermal point). The following figure shows

the pH value to the mV output of the sensor.

Characteristic for pH measurement is an offset

also known as aspot [mV] or zero [pH] and a

Slope [mV/pH]. For an ideal sensor the theo-

retical slope is 59.16 mV/pH at 25ºC. Slope can

be entered in mV/pH or a percentage of the

theoretical slope (100% corresponds to 59.16

mV/pH). ITP is where the output of the sensor

does not change with temperature. Note that

slope and zero are defined at 25ºC.

pH

mV

ITP

As pot

0 mV

mV

500

0

- 200

14

pH

ITP Zero

0

7

Figure 5-1. Calibration parameters

Units

Zero (aspot) unit. Zero is an alternative to

Asymmetry Potential. This method conforms to

the DIN standard for instruments IEC 60146-2.

Zero is defined in pH or mV.

Slope (sensitivity) unit

Slope can be defined in mV/pH or defined as

percentage of theoretical slope at 25ºC.

Limits and timing

Zero (aspot) High, Low. During calibration the

new zero is checked for exceeding these low

and high limits. Narrowing the band will prevent

bad calibration procedures and calibration of

bad sensors, which results in higher accuracy.

The default values should be adjusted to suit

the application and the “users” criterion.

Slope (sensitivity) high, low

During calibration the new slope is checked for

exceeding these low and high limits. Narrowing the

band will prevent bad calibration procedures and

calibration of bad sensors, which results in higher

accuracy. The default values should be adjusted to

suit the application and the “users” criterion.

Stabilization time

During calibration, the value should be stable

within 0.01 pH over this stabilization time pe-

riod. When the pH value is not stable within 10

minutes, calibration is aborted.

Calibration interval

The interval in which a new calibration must

take place. If the interval is exceeded the

instrument will give a warning or a fail (user

definable in error configuration 2/3)

Buffers

Calibration is done using standard calibration

buffers. Our preference goes to NIST buffers

for highest accuracy, but the user is free to

select US, DIN or define his own. The standard

buffers can be found in Appendix 1.

Zero (aspot)/slope (sensitivity)/ITP

Zero (aspot), Slope (sensitivity), ITP values can

be entered directly in this section. These data can

be provided by the manufacturer of the probe, or

by the users laboratory etc. They are determined

independently of the measuring loop.

Note! it is not necessary to enter this data. In

most cases as the EXAxt automatically

does this while performing a calibration.

The feature is used in the case of special

electrode systems and where calibration

in the process environment is not

possible. See chapter 6.

5-6. Impedance setting

Reference impedance High, Low. The EXAxt

has an impedance check, capable of moni-

toring the impedance of all sorts of sensor

systems. In order to “fine tune” this diagnostic

tool it is necessary to set it up to match the

sensors used.

The system is set to measure the impedance of

Glass (high) and reference (low) electrodes.

In applications that have a tendency to leave

deposits on the electrodes and to clog the

reference sensor junction there is the possibility

to use the impedance check (set error configu-

ration) on the reference sensor to initiate an

alarm, or to initiate the wash cleaning process,

when one of the limits is exceeded.