Yokogawa EJX118A User Manual

Page 57

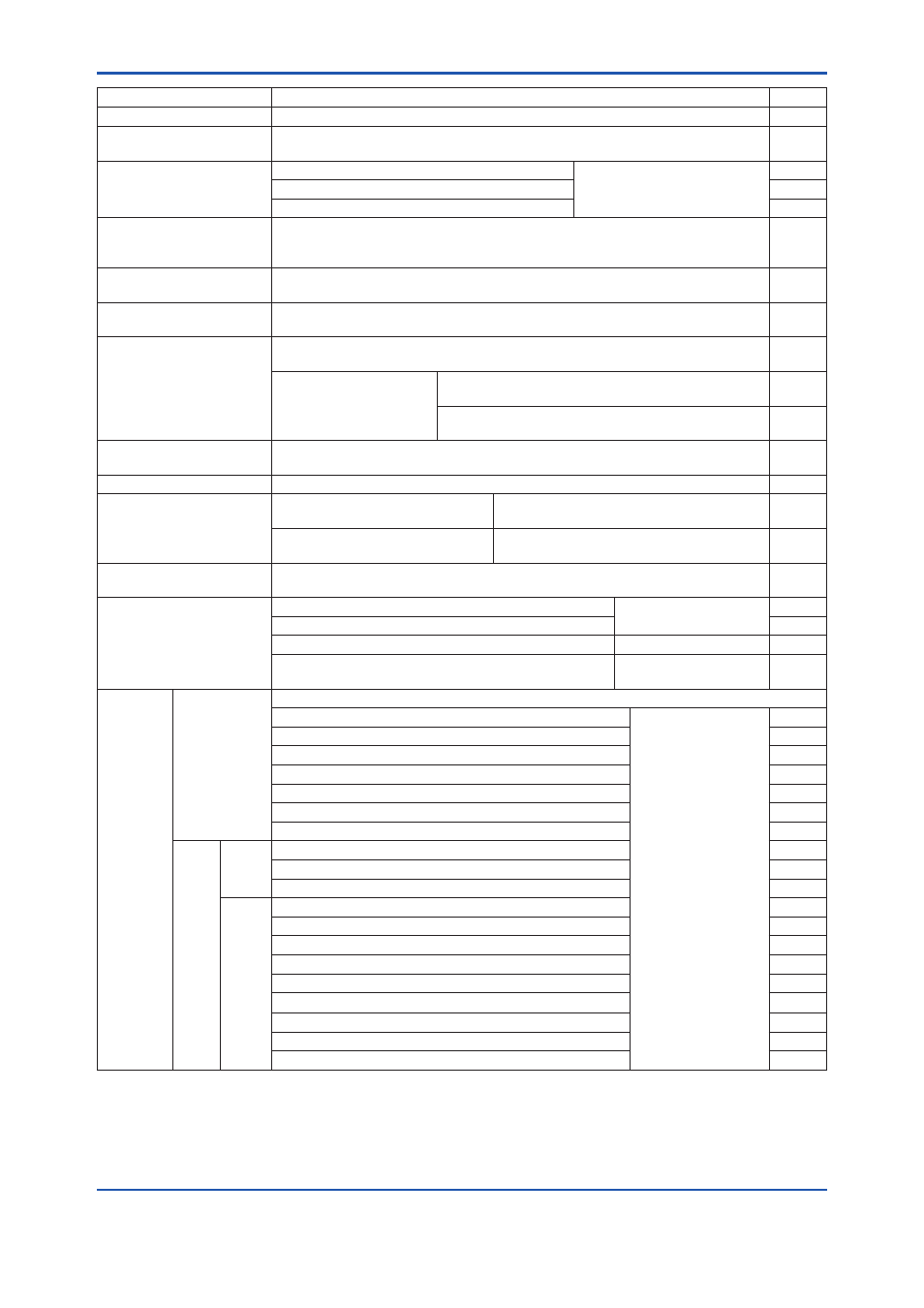

<8. General Specifications>

8-15

IM 01C25H01-01E

Item

Description

Code

Oil-prohibited use

Degrease cleansing treatment.

K1

Oil-prohibited use

with dehydrating treatment

Degrease cleansing and dehydrating treatment.

K5

Calibration units *

6

P calibration (psi unit)

(See Table for Span and

Range Limits.)

D1

bar calibration (bar unit)

D3

M calibration (kgf/cm

2

unit)

D4

Teflon film

*5 *11

Diaphragm protection from sticky process fluid by FEP Teflon film attached with

fluorinated oil.

Operation range: 20 to 150°C, 0 to 2 MPa (Not applicable for vacuum service).

TF1

Operating temperature

correction

*8

Adjusting range: 80°C to Maximum temperature of specified fill fluid

R

Capillary without PVC

sheaths

When ambient temperature exceeds 100°C, or use of PVC is prohibited

V

Output limits and failure

operation *

7

Failure alarm down-scale: Output status at CPU failure and hardware error is

–5%, 3.2 mA DC or less.

C1

NAMUR NE43 Compliant

Output signal limits:

3.8 mA to 20.5 mA

Failure alarm down-scale: Output status at CPU

failure and hardware error is –5%, 3.2 mA DC or less.

C2

Failure alarm up-scale: Output status at CPU

failure and hardware error is 110%, 21.6 mA or more.

C3

Gold-plate

*9

Inside of isolating diaphragms (fill fluid side) are gold plated, effective for hydrogen

permeation.

A1

Stainless steel tag plate

304SST tag plate wired onto transmitter

N4

Data configuration at

factory *

10

Data configuration for HART

communication type

Software damping, Descriptor, Message

CA

Data configuration for BRAIN

communication type

Software damping

CB

Advanced diagnostics

*13

Multi-sensing process monitoring

• Impulse line blockage detection

*14

DG6

Material

certificate

Process flange, Block

For Flush type

M2W

Process flange, Block, Ring

*15

M5W

Process flange, Block, Pipe, Base

For Extended type

M2E

High Pressure side: Process flange, Block, Pipe, Base

Low Pressure side: Process flange, Block

For Combination type

M2Y

Pressure

test/Leak

test

Certificate

*19

EJ

X1

18

A

EJ

A1

18

E

(Flange rating)

(Test pressure)

JIS 10K

2 MPa (290 psi)

Nitrogen (N

2

) Gas

*18

Retention time:

10 minutes

T51

JIS 20K

5 MPa (720 psi)

T54

JIS 40K

*16

10 MPa (1450 psi)

T57

ANSI/JPI Class 150

3 MPa (430 psi)

T52

ANSI/JPI Class 300

*16

8 MPa (1160 psi)

T56

ANSI/JPI Class 300

*17

7 MPa (1000 psi)

T55

ANSI/KPI Class 600

*16

16 MPa (2300 psi)

T58

EJ

X4

38

A,

E

JA

43

8E

Fo

r A

-

C

ap

su

le JIS 10K

2 MPa (290 psi)

T51

JIS 20K, 40K, 63K

3.5 MPa (500 psi)

T53

ANSI/JPI Class 150, 300, 600

3.5 MPa (500 psi)

T53

Fo

r B

-C

ap

su

le

JIS 10K

2 MPa (290 psi)

T51

JIS 20K

5 MPa (720 psi)

T54

JIS 40K

*16

10 MPa (1450 psi)

T57

JIS 40K

*17

7 MPa (1000 psi)

T55

JIS 63K

*16

16 MPa (2300 psi)

T58

ANSI/JPI Class 150

3 MPa (435 psi)

T52

ANSI/JPI Class 300

*16

8 MPa (1160 psi)

T56

ANSI/JPI Class 300

*17

7 MPa (1000 psi)

T55

ANSI/JPI Class 600

*16

16 MPa (2300 psi)

T58

Contact Yokogawa representative for the codes indicated as ‘-’.

*1:

Applicable for Electrical connection code 2, 4, 7, and 9.

*2:

Applicable for Electrical connection code 2 and 7.

*3: Not applicable for option code /AL.

*4: Not applicable with color change option.

*5: Applicable for flush type (process connection style code W.)