Important – Yokogawa EJX118A User Manual

Page 25

<4. Installation>

4-3

IM 01C25H01-01E

IMPORTANT

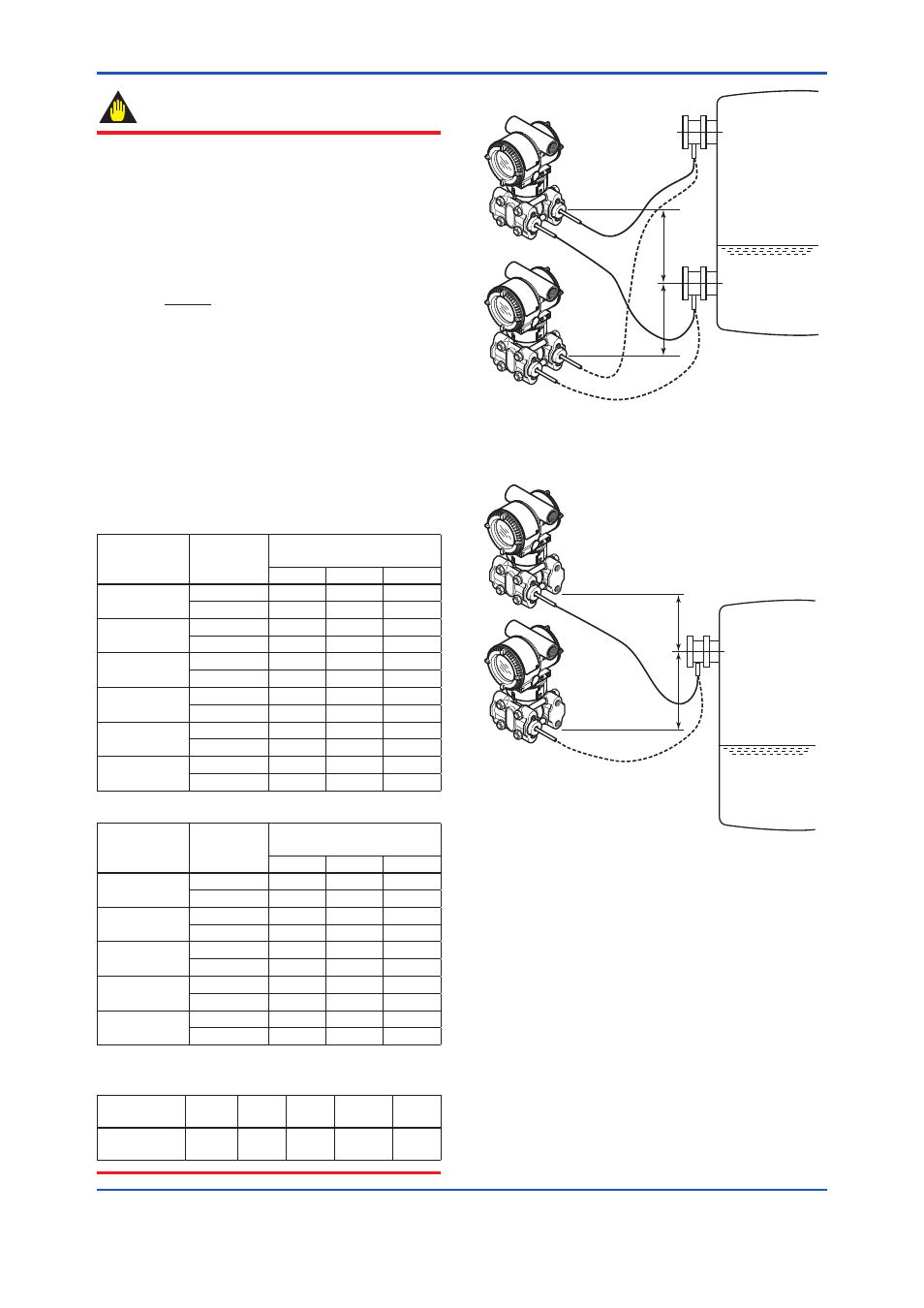

The transmitter should be installed at least 600 mm

below the high pressure (HP) process connection

to ensure a positive head pressure of fill fluid. Pay

special attention to vacuum applications.

If it can not be installed at least 600 mm below the

HP process connection, please use the equation

below:

h=

× 0.102

[mm]

(P–P0)

ds

h: Vertical height between the HP process

connection and the transmitter (mm)

h≤0: Install the transmitter at least h (mm) below

the HP process connection

h>0: Install the transmitter at most h (mm) above

the HP process connection

P: Pressure in the tank (Pa abs)

P0: Minimum working pressure limit of the

transmitter (Pa abs). See below table.

[For fill fluid code A, B, C, D, E]

Wetted parts

material

code

Capillary

length

Process connection size

code

2, 8

3

4,W

SW

1 to 5 m

6790

3190

6 to 10 m

10030

3520

SE

1 to 5 m

6790

3190

6 to 10 m

10030

3520

SY

1 to 5 m

3190

6 to 10 m

3520

HW

1 to 5 m

19150

6140

6 to 10 m

8290

TW

1 to 5 m

9620

3620

6 to 10 m

4210

UW

1 to 5 m

9540

4750

6 to 10 m

6050

[For fill fluid code 1, 2, 4]

Wetted parts

material

code

Capillary

length

Process connection size

code

2, 8

3

4,W

SW

1 to 5 m

2570

320

6 to 10 m

4680

530

SE

1 to 5 m

2570

320

6 to 10 m

4680

530

SY

1 to 5 m

320

6 to 10 m

530

HW

1 to 5 m

10220

2050

6 to 10 m

3450

TW

1 to 5 m

4270

570

6 to 10 m

960

ds: Specific gravity of fill fluid (at 25°C). See below

table.

Fill fluid

code

A, 1, 4

B

C, 2

D

E

ds: Specific

gravity

1.07

0.94

1.09

1.90 to

1.92

1.09

F0404.ai

P

Low pressure side

High

pressure

side

(+)

(–)

0

h

Figure 4.4

Example of Installation to Tank for

Differential Pressure Transmitter

(Caution on Installation)

F0405.ai

(+)

0

(–)

P

h

Figure 4.5

Example of Installation to Tank for

Gauge Pressure Transmitter

(Caution on Installation)