2 replacing the cpu board assembly, 5 troubleshooting, 1 basic troubleshooting – Yokogawa EJX118A User Manual

Page 39: Replacing the cpu board assembly -4, Troubleshooting -4 7.5.1, Basic troubleshooting -4

<8. Maintenance>

7-4

IM 01C25H01-01E

F0703.ai

Press

forward

Output terminal cable

Zero-adjustment

screw pin

Slide

switch

Boss

Zero-

adjustment

screw

Integral

indicator

Mounting screw

Amplifier Cover

CPU assembly

Bracket

(for zero-adjustment

screw pin)

LCD board assembly

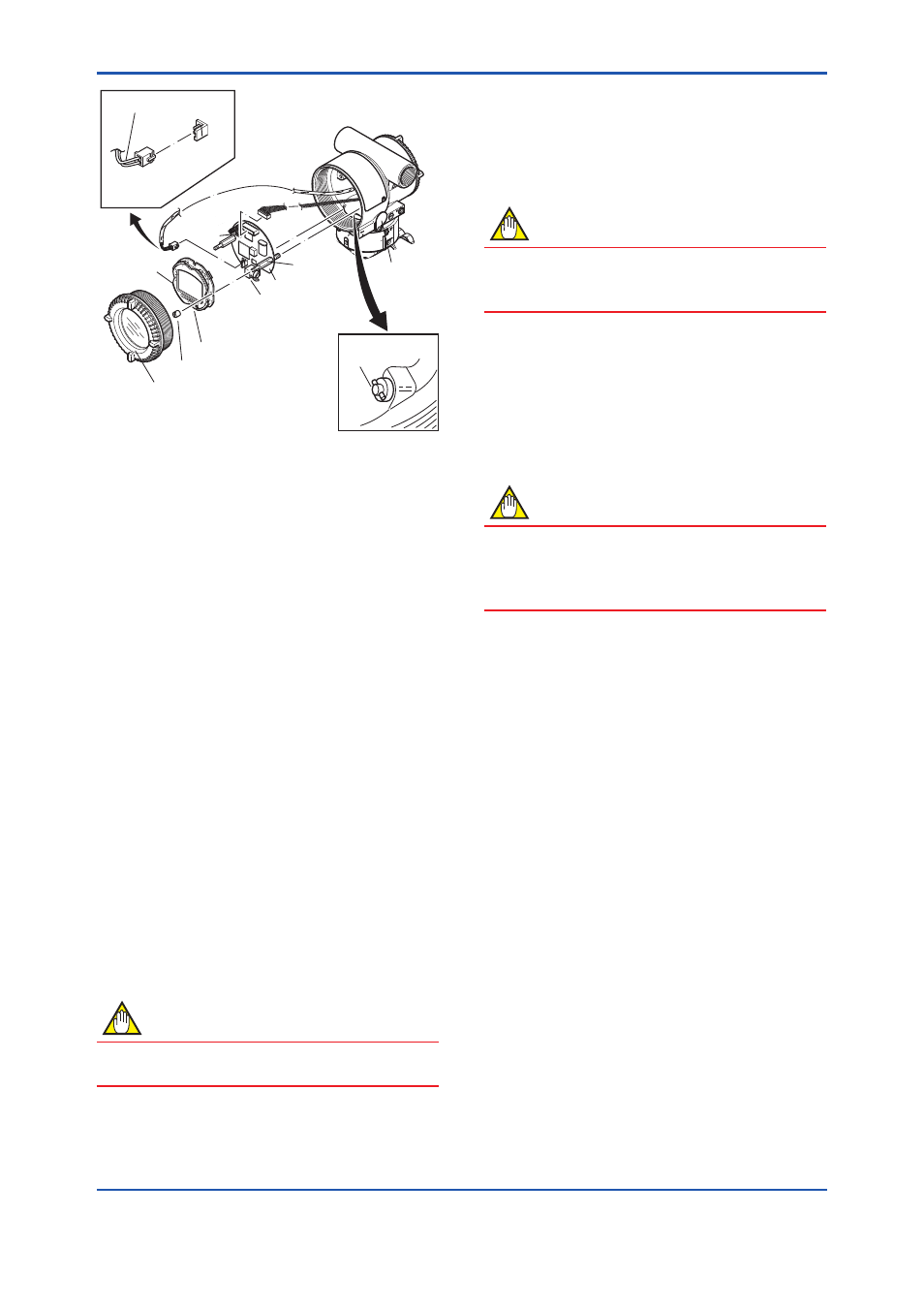

Figure 7.3

Removing and Attaching LCD Board

Assembly and CPU Assembly

7.4.2 Replacing the CPU Board Assembly

This subsection describes the procedure for

replacing the CPU assembly. (See figure 7.3)

■ Removing the CPU Assembly

1) Remove the cover. If an integral indicator is

mounted, refer to subsection 7.4.1 and remove

the indicator.

2) Turn the zero-adjustment screw to the position

(where the screw head slot is horizontal) as

shown in figure 7.3.

3) Disconnect the output terminal cable (cable

with brown connector at the end). When doing

this, lightly press the side of the CPU assembly

connector and pull the cable connector to

disengage.

4) Use a socket driver (width across flats, 5.5mm)

to loosen the two bosses.

5) Carefully pull the CPU assembly straight

forward to remove it.

6) Disconnect the flat cable (cable with white

connector at the end) that connects the CPU

assembly and the capsule.

NOTE

Be careful not to apply excessive force to the

CPU assembly when removing it.

■ Mounting the CPU Assembly

1) Connect the flat cable (with white connector)

between the CPU assembly and the capsule.

2) Connect the output terminal cable (with brown

connector).

NOTE

Make certain that the cables do not get pinched

between the case and the edge of the CPU

assembly.

3) Align and engage the zero-adjustment screw

pin with the groove on the bracket on the CPU

assembly. Then insert the CPU board assembly

straight onto the post in the amplifier case.

4) Tighten the two bosses. If the transmitter is

equipped with an integral indicator, refer to

subsection 7.4.1 to mount the indicator.

NOTE

Confirm that the zero-adjustment screw pin is

placed properly in the groove on the bracket prior

to tightening the two bosses. If it is not, the zero-

adjustment mechanism will be damaged.

5) Replace the cover.

7.5 Troubleshooting

If any abnormality appears in the measured values,

use the troubleshooting flow chart below to isolate

and remedy the problem. Since some problems

have complex causes, these flow charts may

not identify all. If you have difficulty isolating or

correcting a problem, contact Yokogawa service

personnel.

7.5.1 Basic Troubleshooting

First determine whether the process variable

is actually abnormal or a problem exists in the

measurement system.

If the problem is in the measurement system,

isolate the problem and decide what corrective

action to take.