Installation, 1 precautions, 2 mounting the diaphragm seals – Yokogawa EJX118A User Manual

Page 23: Installation -1, Precautions -1, Mounting the diaphragm seals -1, Important

<4. Installation>

4-1

IM 01C25H01-01E

4. Installation

4.1 Precautions

Before installing the transmitter, read the cautionary

notes in Section 2.4, “Selecting the Installation

Location.” For additional information on the ambient

conditions allowed at the installation location, refer

to Subsection 8.1 “Standard Specifications.”

IMPORTANT

• When welding piping during construction,

take care not to allow welding currents to

flow through the transmitter.

• Do not step on this instrument after

installation.

• For the EJ438, there is a small hole in

the low pressure side cover flange that is

used to measure the atmospheric pressure.

The hole must not face upward. See section

8.4, “Dimensions,” for the location of the

hole.

• Never loosen the four bolts securing the

cover flanges (Refer to figure 3.2.) If the seal

liquid leaks, the transmitter cannot be used.

4.2 Mounting the Diaphragm

Seals

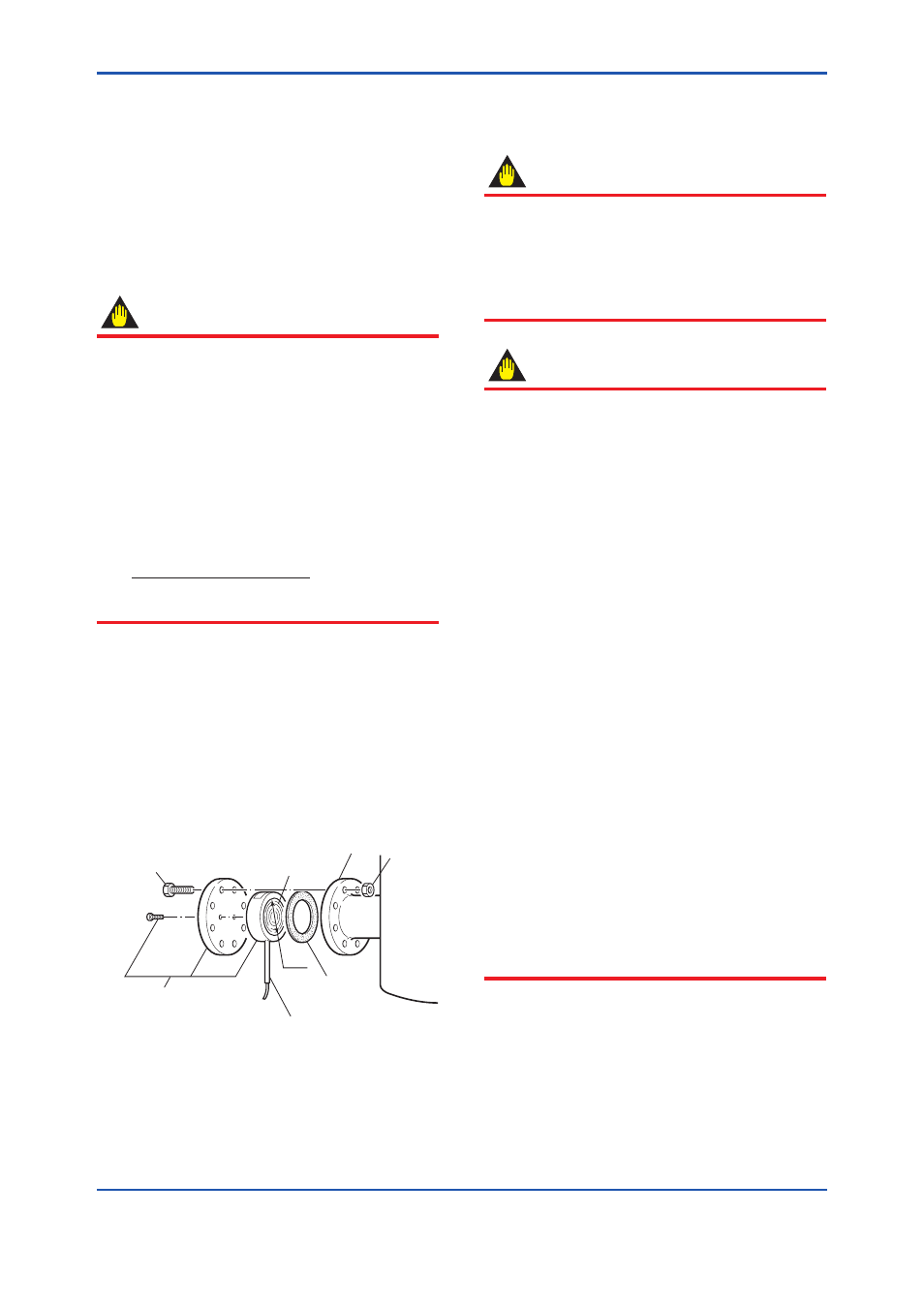

Mount the diaphragm seals using the flanges as

shown in Figure 4.1 Figure 4.2 shows how to mount

the diaphragm seals on a tank. The mating flange,

gasket, bolts and nuts are to be procured by the

customer.

Nut

Flange

Diaphragm

Ød

Gasket

F0401.ai

Bolt

The product is shipped with

these parts assembled.

Correctly install the diaphragm seals on

the high and low pressure sides of the

process (The label on each diaphragm

seal is marked

HIGH or LOW.)

Figure 4.1

Mounting the Diaphragm Seals

IMPORTANT

Please use a gasket with an inside diameter

(ød) that is greater than the diameter of the

diaphragm seal. If a gasket with a smaller

inside diameter is used, the diaphragm may

not function correctly. (Refer to Subsection 8.4

‘Dimensions’)

IMPORTANT

• When measuring the liquid level of the tank,

the minimum liquid level (zero point) must

be set to a level at least 50 mm above the

center of the high pressure side diaphragm

seal (see Figure 4.2).

• Correctly install the diaphragm seals on the

high and low pressure sides of the process,

checking the label on each seal.

• To avoid measuring error duets temperature

difference between the two diaphragm

seals, capillary tube must be bound together.

The capillary tube must be securely fixed

to the tank wall to prevent movement by

wind or vibration. If the capillary tube is too

long, loosely coil the extra tube portion (coil

diameter of 300 mm or more) and secure the

coiled tube with a clamp.

• During the diaphragm seal installation,

ensure as far as possible that no seal liquid

head pressure is applied to the diaphragm

seals.

• Exercise care so as not to damage

diaphragm surfaces. Since the diaphragm

protrudes approx. 1 mm from the flange

surface, do not place the pressure detector

section face down on a surface as this can

damage the diaphragm.

• Do not sharply bend or twist capillary tube or

apply excessive stress to them.