Yokogawa EJX118A User Manual

Page 46

<8. General Specifications>

8-4

IM 01C25H01-01E

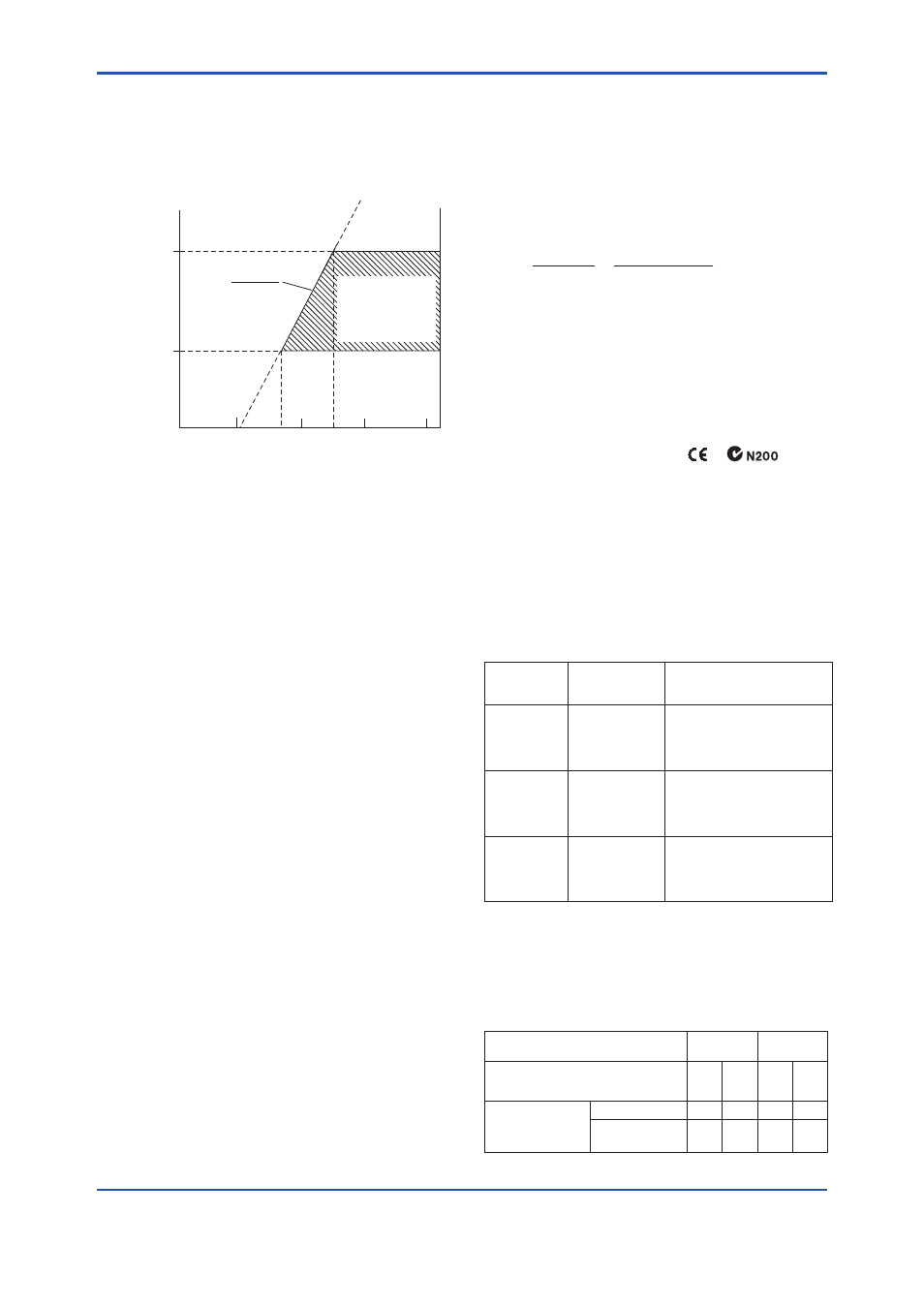

Supply & Load Requirements “◊”

(Optional features or approval codes may

affect electrical requirements.)

With 24 V DC supply, up to a 550 Ω load can be

used. See graph below.

E-10.5

0.0244

Power supply voltage E (V DC)

600

250

R (Ω)

10.5

16.6

25.2

42

External load

resistance

Digital

Communication

range

BRAIN and HART

R=

F0803.ai

Figure 8.3

Relationship Between Power Supply

Voltage and External Load Resistance

Supply Voltage

10.5 to 42 V DC for general use and flameproof

type.

10.5 to 32 V DC for lightning protector (Option

code /A).

10.5 to 30 V DC for intrinsically safe, type n or

non-incendive type.

Minimum voltage limited at 16.6 V DC for digital

communications, BRAIN and HART

Load (Output signal code D, E and J)

0 to 1290 Ω for operation

250 to 600 Ω for digital communication

Communication Requirements “◊”

(Safety approvals may affect electrical

requirements.)

BRAIN

Communication Distance

Up to 2 km (1.25 miles) when using CEV

polyethylene-insulated PVC-sheathed cables.

Communication distance varies depending on

type of cable used.

Load Capacitance

0.22 µF or less

Load Inductance

3.3 mH or less

Input Impedance of communicating device

10 kΩ or more at 2.4 kHz.

HART

Communication Distance

Up to 1.5 km {1 mile} when using multiple

twisted pair cables. Communication distance

varies depending on type of cable used.

Use the following formula to determine cable

length for specific applications:

L=

–

65 × 10

6

(R × C)

(C

f

+ 10,000)

C

Where:

L = length in meters or feet

R = resistance in Ω (including barrier

resistance)

C = cable capacitance in pF/m or pF/ft

C

f

= maximum shunt capacitance of receiving

devices in pF/m or pF/ft

EMC Conformity Standards

,

EN61326-1 Class A, Table2 (For use in industrial

locations)

EN61326-2-3

Physical Specifications

Process connections

See the following table.

Table 8.2

Flange size and rating

Process

connection

style

Size

Flange

Flush type

3-inch

2-inch

1 1/2-inch

*1

JIS 10K, 20K, 40K, 63K

*2

ANSI Class 150, 300, 600

JPI Class 150, 300, 600

DIN PN10/16, 25/40, 64

Extended

type

4-inch

3-inch

JIS 10K, 20K, 40K

*2

ANSI Class 150, 300

JPI Class 150, 300

DIN PN10/16, 25/40

Combination

type

*3

(Extended

and Flush)

High pressure

side: 4-inch

Low pressure

side: 3-inch

JIS 10K, 20K

ANSI Class 150, 300

JPI Class 150, 300

DIN PN10/16, 25/40

*1:

Flushing connection rings are always attached.

*2:

Applicable for EJ438 only.

*3:

Applicable for EJ118 only.

Gasket Contact Surface

See the following table.

Table 8.3

Gasket contact surface

Flange

JIS/JPI/

DIN

ANSI

Wetted parts material code

SW

SE

SY

HW

TW

UW

SW

SE

SY

HW

TW

UW

Gasket contact

Surface

Serration

*1

—

—

—

Flat

(No serration)

: Applicable, —: Not applicable

*1: ANSI B16.5