Troubleshooting – Watlow Series L Temperature Limit User Manual

Page 13

Wa t l ow S e r i e s L

• 11 • C h a p te r

5 :

Tro u bl e s h o o t i n g

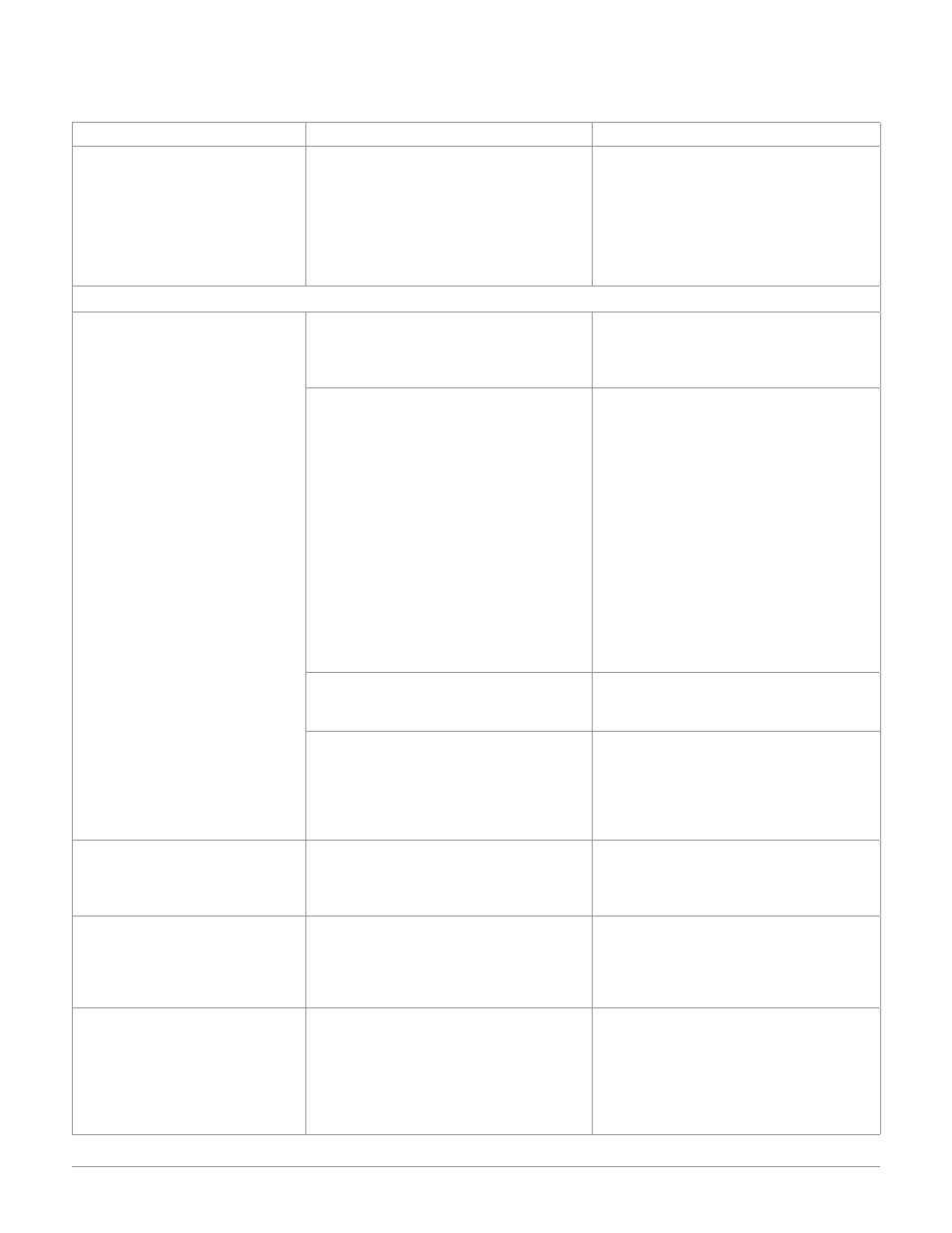

Indication

Probable Cause(s)

Corrective Action

On indicating limits, the dis-

play is not illuminated.

• Power supply switch off.

• Fuse blown.

• Breaker tripped.

• Safety interlock door switch activated.

• Wiring incorrect or open.

• Power supply voltage incorrect.

• Defective limit.

• Turn switch on.

• Replace fuse (check cause of failure).

• Reset breaker (check cause of failure).

• Close door.

• Check wiring.

• Verify input power

• Repair or replace limit.

Troubleshooting thermocouple inputs

Temperature reading is incor-

rect, showing a sensor error,

[Er;In] , or ALARM LED is

switching at the wrong tem-

perature.

• Setting for degree C or F is incorrect. • Check the model part number for

Degree C or F. If the model has Incre-

ment/Decrement keys, then the C/F

setting is adjustable.

• Sensor or limit may be bad. Sensor

connections may be bad.

• Place a jumper wire across the ther-

mocouple input terminals. The display

should indicate ambient temperature.

If it does, the limit is OK.

- For high limit: Start with limit set

point above ambient temperature,

ALARM LED should be off. Decrease

limit set point until ALARM LED goes

on. It should be approximately ambi-

ent temperature.

- For low limit: Start with limit set point

below ambient temperature, ALARM

LED should be off. Increase limit set

point until ALARM LED goes on. It

should be approximately ambient tem-

perature.

• Ambient temperature in the control

cabinet is over 70°C.

• Measure temperature in cabinet to

ensure it is below 70C. Vent cabinet or

add fans if necessary.

• Ground loop problem. Can occur when

using a switched DC output and a

grounded thermocouple.

• Remove power from the system. Use

an ohm meter to measure resistance

between output DC- and the thermo-

couple sheath. If there is continuity,

replace sensor with an ungrounded

thermocouple.

Temperature seems to be de-

creasing, but actual process is

increasing.

• Thermocouple polarity is reversed. In

the US, red wire insulation denotes

the negative wire.

• Check thermocouple connections. All

connections, including extension wire

must maintain the correct polarity.

Correct polarity problems.

Temperature seems to be read-

ing low and not increasing

while actual process tempera-

ture is increasing.

• Sensor is bad. Thermocouple is shorted. • Check thermocouple connections.

Check thermocouple wire insulation

to make sure it is not damaged, caus-

ing the wires to short (making a new

junction).

Temperature seems to be off-

set from actual process tem-

perature, or the ALARM LED

switches on at the wrong tem-

perature. The offset changes

with changes in process tem-

perature.

• Copper wire was used instead of ther-

mocouple extension wire. Connectors

of metals different than thermocouple

metal were used to splice or make

connections.

• Check thermocouple connections.

Check to make sure that only thermo-

couple extension wire of the correct

type was used to extend thermocouple

leads. Replace if necessary.

Troubleshooting