Clutch air shifter adjustment – Ramsey Winch H-800 W/AIR SHIFTER (TALBERT) User Manual

Page 7

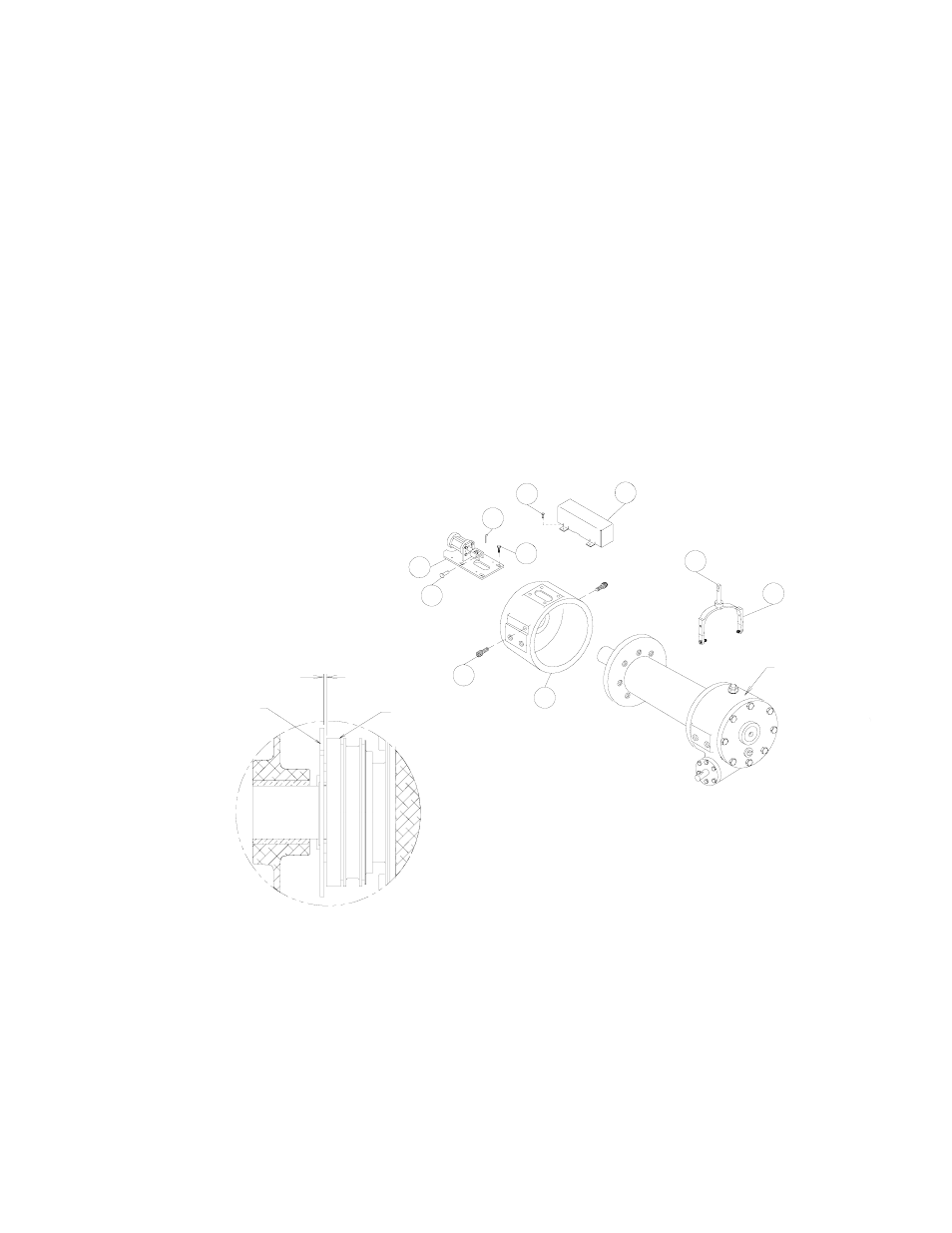

CLUTCH AIR SHIFTER ADJUSTMENT

1. Place winch assembly back into mounting frame and reattach using (8) mounting bolts and lockwashers. Torque

mounting hardware to 290 ft. lbs. each. Make sure that gear housing and clutch housing are not rubbing against

drum flanges.

2. Place air shifter assembly #5 over shifter shaft aligning clevis over flats of shaft. Secure clevis to shaft using

clevis pin #76 and cotter pin #75. Place shifter shaft in the "ENGAGED" position. With the air cylinder shaft fully

retracted, push shifter assembly toward the drum until all play is taken out of the shifter shaft. Secure shifter

assembly to clutch housing using (4) capscrews #46 (flanged hx. hd. serrated). Tighten securely, but do not

torque.

3. Hook up air (70 to 90 psi) to inlet port of air cylinder and disengage clutch. Look into the opening in the clutch

housing and verify that the locking ring and retainer plate are not making contact. Locking ring and retainer plate

must not make contact. There must be a clearance (gap) of .09 inch (max.) between the locking ring and retain-

er plate when the winch is fully disengaged. If there is contact, the (4) capscrews #46 should be loosened and

the plate pulled away from the drum approximately .06 inch. Tighten screws securely and check action to assure

needed clearance. Repeat adjustment procedure as needed to acquire needed gap. Shift clutch 2 or 3 times to

verify proper shifting of clutch. After final adjustment, torque (4) capscrews #46 to 18 ft. lbs. each. Attach

cover #43 using (4) capscrews #61.

PLATE

RETAINER

LOCKING

RING

21

.09 MAX.

76

5

53

46

75

61

37

34

43

WINCH ASSEMBLY

7