Cable tensioner overhaul – Ramsey Winch H-800 W/AIR SHIFTER (TALBERT) User Manual

Page 17

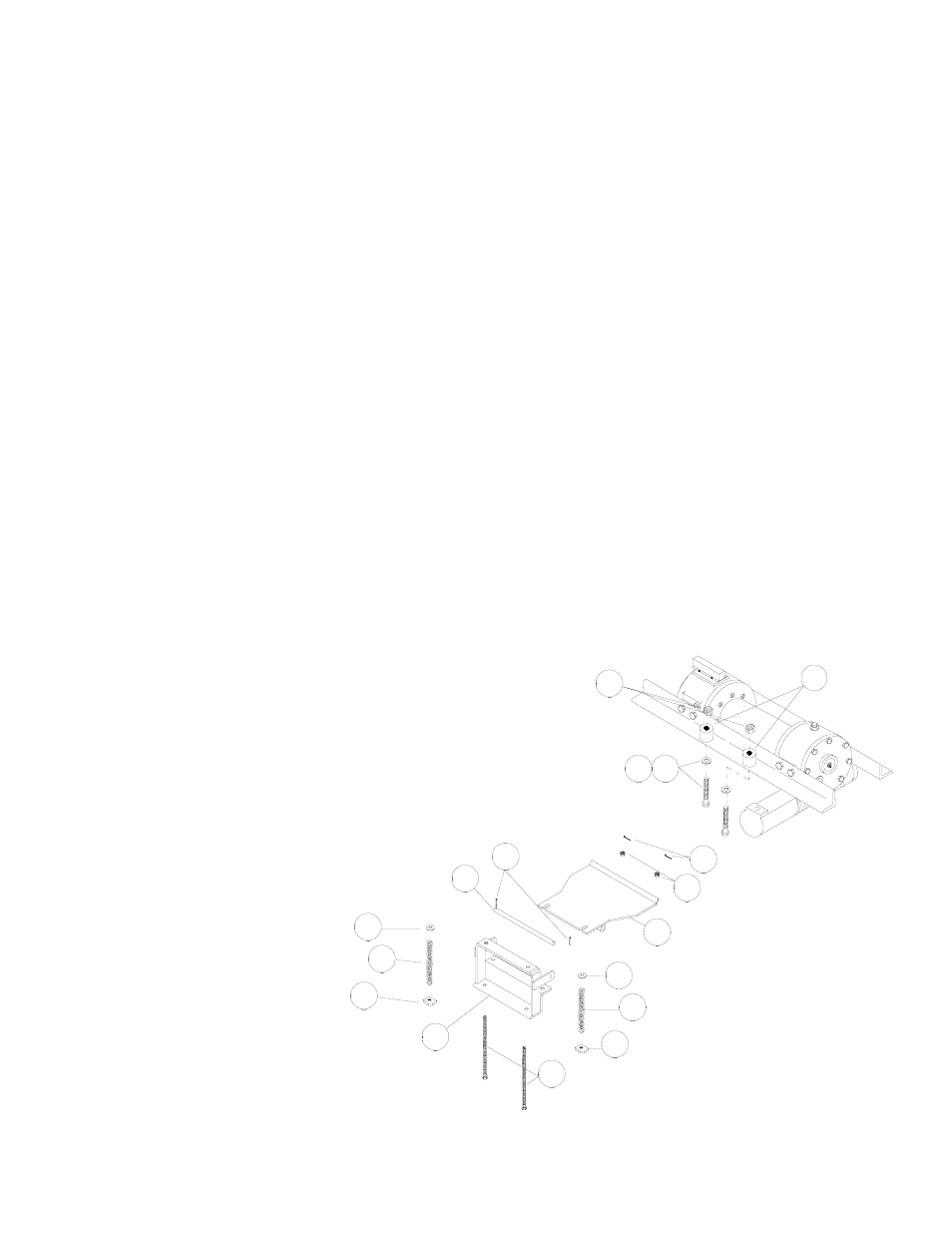

CABLE TENSIONER OVERHAUL

If the cable tensioner needs to be overhauled, it will need to be re-assembled and adjusted for the proper freespool

effort. Do not operate the winch with the tensioner against a bare drum. The winch should only be operated

with the cable tensioner installed with at least one wrap of cable around the drum.

(1)

To remove the tensioner from the winch, remove the capscrews (item #47), lockwashers (item #68), and nuts (item

#63) that mount the tensioner to the angle. Disassemble the tensioner assembly as shown below. Replace any parts

that are worn.

(2)

Re-assemble the tensioner assembly. Mount the assembly to the angle using the spacers (item #32)

under the tensioner bracket. Center the tensioner plate (item #2) between the drum flanges using a

tape measure or scale. Tighten the mounting bolts to 87 ft-lbs. of torque.

(3)

Before increasing tension on the cable tensioner, the cable should be installed on the drum. As cable

winds onto the drum, watch the tensioner. The tensioner must be free to move without obstruction to

function properly. If the tensioner touches either drum flange, correct the problem.

(4)

To adjust the freespool effort of the tensioner, turn the adjustment nut (item #72) or the tensioner

stud (item #4). This will adjust the spring height. Start adjusting the tensioner with the spring height

at 5.50”. Disengage the winch and freespool some cable off the drum. Adjust the spring tension to

achieve the desired freespool effort that also prevents “bird nesting” of the cable.

25

73

2

73

72

26

69

97

97

69

4

26

68

63

47

1

32

17