Ramsey Winch HD-P 42 User Manual

Page 12

10

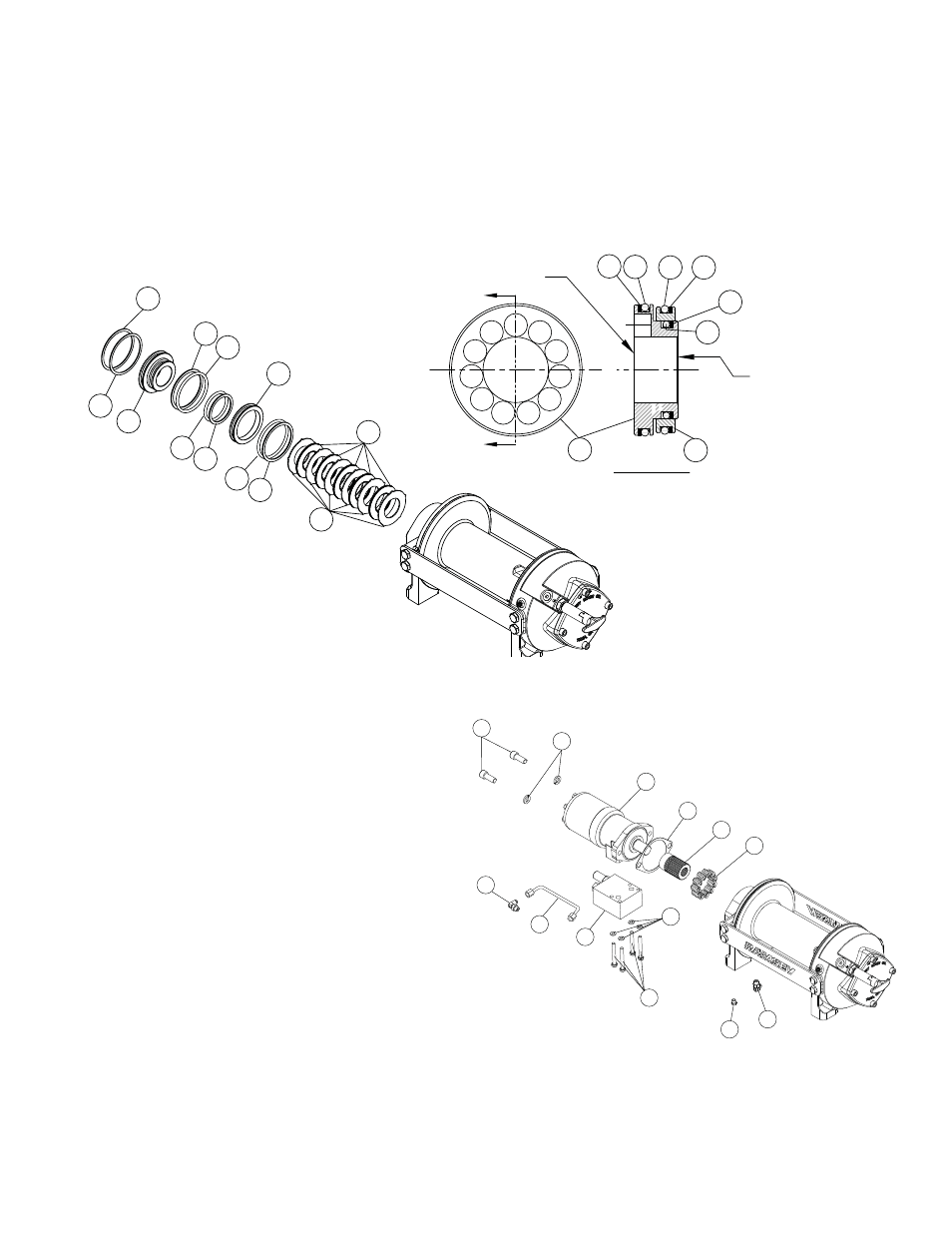

Set winch with gear housing end down on work surface.

Install well-oiled o-rings and backup rings into grooves on outside of brake piston and backup brake piston as

shown in cross-section A-A below.

Piston, backup piston, brake discs and stators must be clean and free of grease and oil.

Insert brake discs (item #4) and stators (item #3) into gear end alternating, with stators first and last.

Insert backup brake piston (item #6) into motor end and insert brake piston (item #5) into it. Apply even

pressure on piston when installing.

Install retaining rings (item #39 and #48) into grooves in motor end housing.

DRUM SIDE

MOTOR SIDE

33

28

32

30

29

31

6

5

4

3

32

30

6

28

33

29

31

5

39

48

SECTION A-A

A

A

Insert springs (item #40) into pockets in back of brake

piston. Install roll pin (item #35) into new motor

coupling below bottom of spline teeth. Insert motor

coupling (item #23), engaging it with the discs and the

input shaft.

Place gasket (item #25) on mounting surface of motor

(item #27). Slide motor shaft into coupling. Attach motor

to motor end bearing housing using (2) capscrews (item

#18) and (2) lockwashers (item #22). Evenly tighten to

66 Nm (49 ft-lb) torque.

Install the counterbalance valve (item #42) to the motor

using (4) capscrews (item #14) and (4) lockwashers

(item #21). Tighten to 23 Nm (17 ft-lb).

Securely connect fittings (item #24) to motor end

housing and counterbalance valve, and connect tube

assembly (item #41) to fittings.

Apply at least 37,9 bar (550 PSI) hydraulic system

pressure to brake and verify that brake releases (winch

drum will rotate).

18

22

27

25

23

40

24

45

14

21

42

41

24