Typical layout – Ramsey Winch RPH-35000 User Manual

Page 5

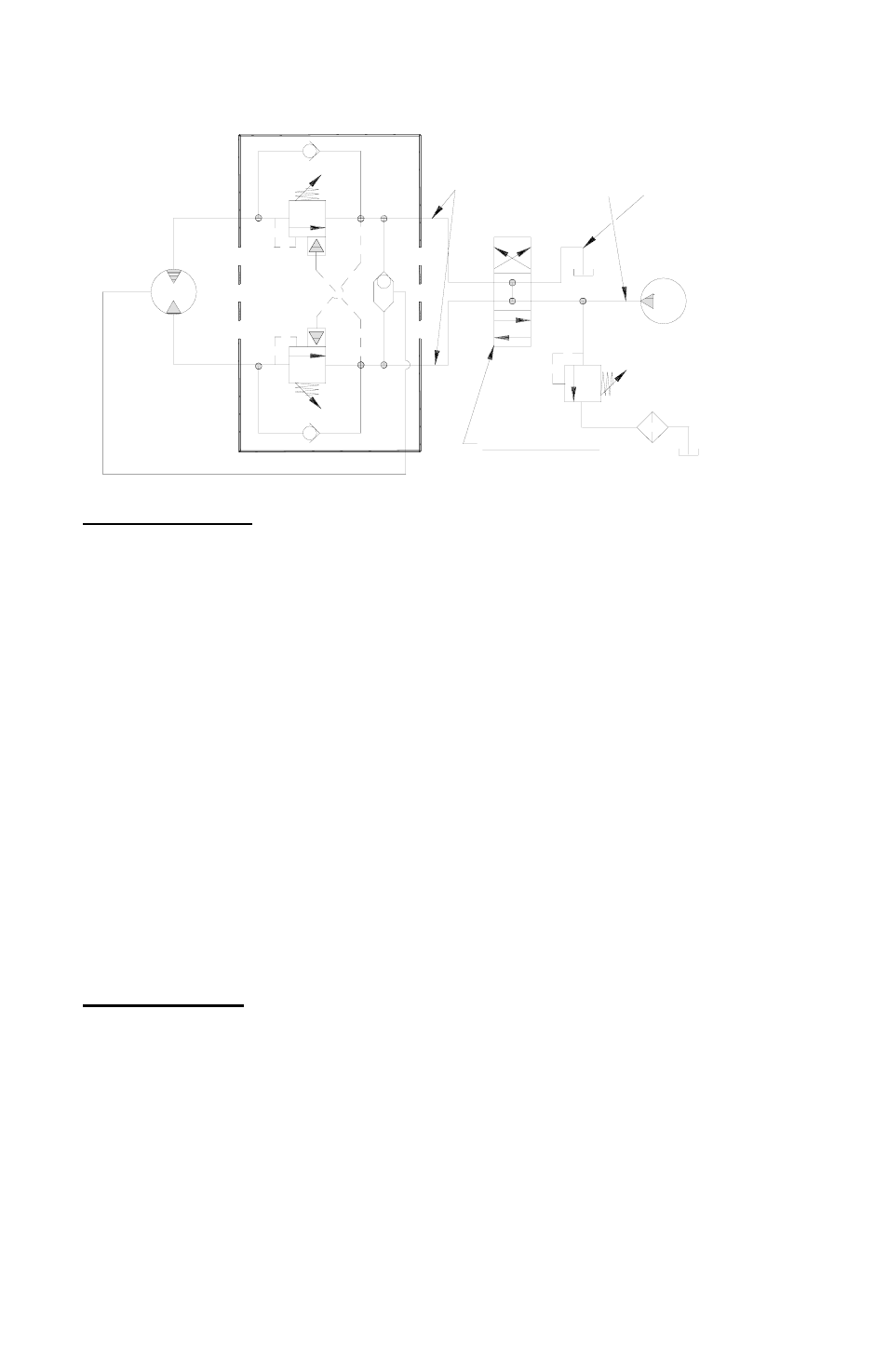

CONTROL VALVE

3 POSITION

4 WAY VALVE

(MOTOR SPOOL)

HIGH PRESSURE LINE

DUAL-A & B PORT CONTROL

WITH BRAKE RELEASE SHUTTLE

BRAKE

PORT

B

MOTOR

A

TYPICAL LAYOUT

LOW PRESSURE LINE

PUMP

CLUTCH OPERATION

To engage clutch:

1.

Move the clutch control valve to the "clutch-engaged" position.

2.

Anytime the temperature is below freezing, run motor in the "cable out" direction only

until the drum starts to turn. In extreme cold temperatures (below 0° F/-18° C), pull out

on the cable by hand only until the drum starts to turn.

3.

Wait at least 3 seconds for the clutch to fully engage, after which the winch is ready to

winch in the cable.

WARNING: Do not attempt to engage the clutch by first running the

winch motor and then moving the clutch control valve to the "clutch-

engaged" position while the motor is running. Do not start picking up

the load at the same time the clutch is being engaged.

To disengage clutch:

1.

Run the winch in the "cable out" direction until the load is off the cable.

2.

Move the clutch control valve to the "clutch-disengaged" position.

3.

The cable may now be pulled off by hand

WINCH OPERATION

The best way to get acquainted with how your winch operates is to make test runs before

you actually use it. Plan your test in advance. Remember, you hear your winch as well as

see it operate. Get to recognize the sounds of a light steady pull, a heavy pull, and sounds

caused by load jerking or shifting. Gain confidence in operating your winch and its use will

become second nature with you.

The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable

pileup on one end of drum. If this happens reverse the winch to relieve the load and move

your anchor point further to the center of the vehicle. After the job is done you can unspool

and rewind for a neat lay of the cable.

3