Winch mounting configurations – Ramsey Winch RPH-35000 User Manual

Page 14

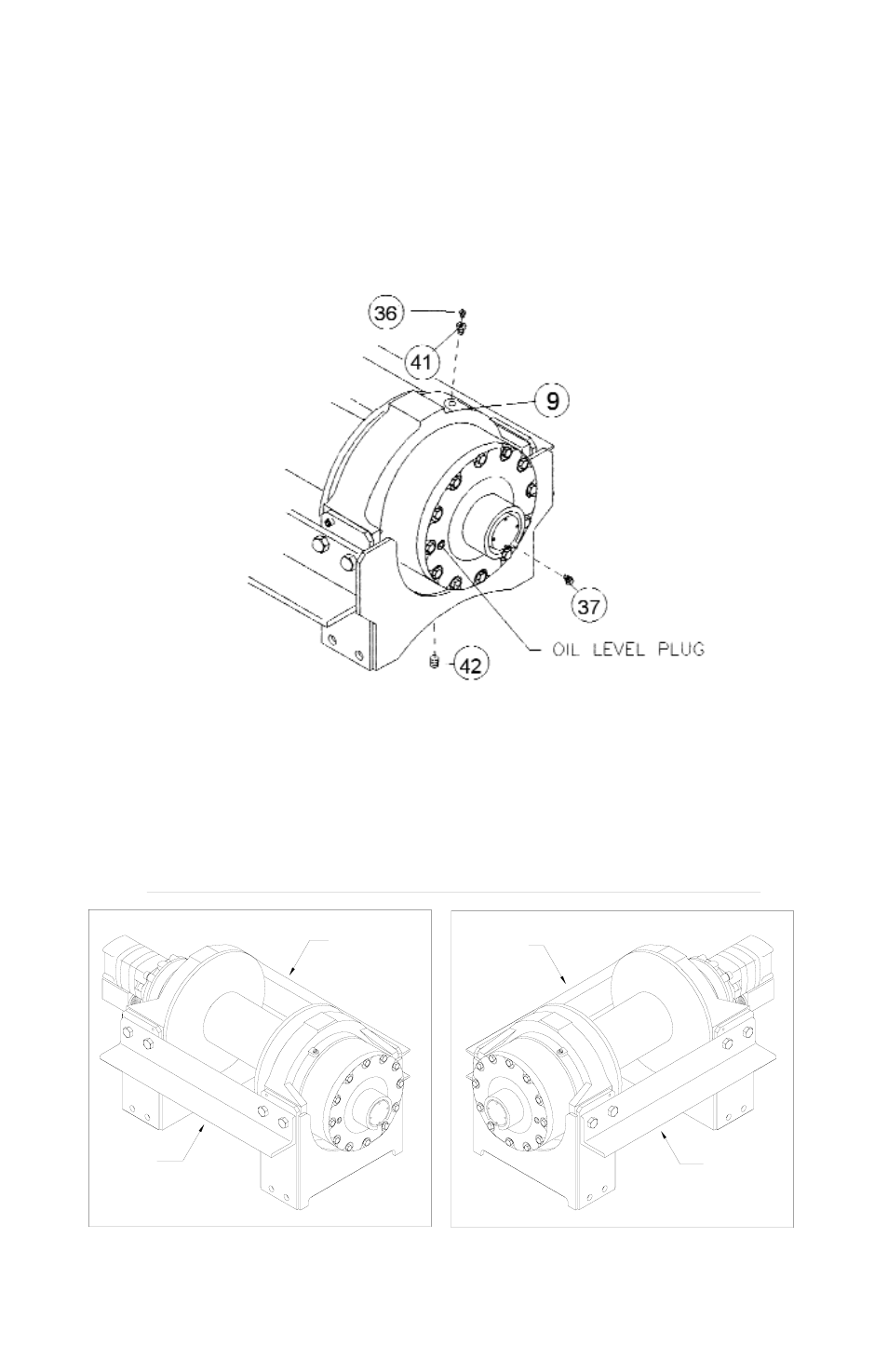

14. Apply Permatex to threads of plug (item #42). Thread plug into tapped hole in bottom of

gear housing end bearing (item #9). Pour approx. 2-1/2 pints of SAE 80W-140 oil into

end bearing. Check oil level by removing oil level plug noted below. Insert relief fitting

(item #36) and thread reducer (item #41) into end bearing at oil fill hole. Be sure the

breather vent (item #37) is not damaged and in good operating condition. Replace if

necessary.

Install winch and connect pressure lines. Bleed pressure release section of brake by loos-

ening bleeder fitting on brake and allowing air to escape while slowly applying hydraulic

system pressure to the winch. Apply at least 230 PSI pressure to release brake and verify

that brake releases, by observing that the winch drum rotates.

15. Check proper operation of clutch by applying air pressure to clutch air cylinder to disen-

gage clutch. Verify that winch freespools. Re-engage clutch. A loud noise should be

heard when clutch engages. Winch drum should not freespool.

16. Operate winch forward and reverse to verify that drum rotates.

ANGLE

SIDE

CHANNEL SIDE

CHANNEL

SIDE

ANGLE SIDE

WINCH MOUNTING CONFIGURATIONS

R. H. MOUNTING

CONFIGURATION

L. H. MOUNTING

CONFIGURATION

12