Paasche Airbrush A-AU-PL User Manual

A-au, Automatic spray gun

DESCRIPTION:

The A-AU Automatic Spray Gun, is a light duty air actuated

production spray gun. It will cover a range of materials to include

light lacquers, latex, acid or corrosives. When using Extensions,

material must be pressure fed for proper application.

CONNECTIONS:

Connections to the gun are: Air Inlet 1/4" N.P.T. (F) and Fluid

Inlet 1/4" N.P.T. (M). A-AU Automatic Spray Gun dimensions are:

5-1/8" (L) x 2-1/4" (D)

PACKING WASHERS:

Washers are made of leather and treated in oil. For PTFE

Packings see parts list, Page 3.

OPERATION:

1. Mount Gun in desired position

2. Before installing, blow out air hoses with compressed air to

remove foreign particles.

3. Connect hose from air supply to air inlet fitting.

4. Connect fluid hose to fluid inlet supply.

5. Tighten all hose connections securely.

6. Adjust air pressure to 45-55 P.S.I. at the Air Regulator.

7. Adjust fluid volume by turning the U-3178 Fluid Adjusting

Knob to the left or right.

NOTE: DO NOT USE U-3178 AS A SHUT-OFF BY TURNING

ALL THE WAY DOWN - IT MAY SPLIT THE TIP.

TIP REMOVAL:

1. Turn off Air and Fluid Pressure.

2. Release Needle pressure from the seat of Tip, by backing

off the U-3178 Fluid Adjusting Knob approximately 5 turns,

then removing U-2686A Cylinder Cap Assembly.

3. Loosen AU-12 Aircap Nut and remove Spray Head

Assembly. Leave Needle In Place.

4. Unscrew AU-Tip. Place New AU-Tip in position.

5. To replace, reverse above procedure.

MAINTENANCE:

Requirements of the A-AU Automatic Spray Gun have been

reduced to a minimum. The leather packing washers should be

lubricated once a month with a light oil. Old Packing Washers

cause leakage of Air or Fluid and replacement should be made.

PTFE Packings are self-lubricating.

A-AU

Automatic Spray Gun

OPERATING INSTRUCTIONS AND REPLACEMENT PARTS

INSTRUCTIONS & PARTS LIST A-AU-8/31/2011

Supersedes Instructions & Parts List A-AU-6/2008

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: [email protected]

Printed in the U.S.A.

WARNING: Spray materials may be harmful if inhaled or

allowed to come into contact with the skin or eyes. Consult

the product label and Material Safety Data Sheet supplied

for the spray material. Follow all safety precautions.

CAUTION: Well Ventilated Area Required to remove

fumes, dust or overspray. Secure airhose and fluid

hose wrench tight for safety and to prevent leaks.

M a x i m u m A i r P r e s s u r e 1 0 0 P . S . I .

M a x i m u m F l u i d P r e s s u r e 4 5 P. S . I .

CLEANING:

Flush clean solvent through the Fluid passages of the Spray Gun

and Wipe off the outside with clean solvent. Never leave the

entire Spray Gun immersed in solvent. Dirty Aircaps and Tips

should be cleaned by soaking in solvent and blown clean with air.

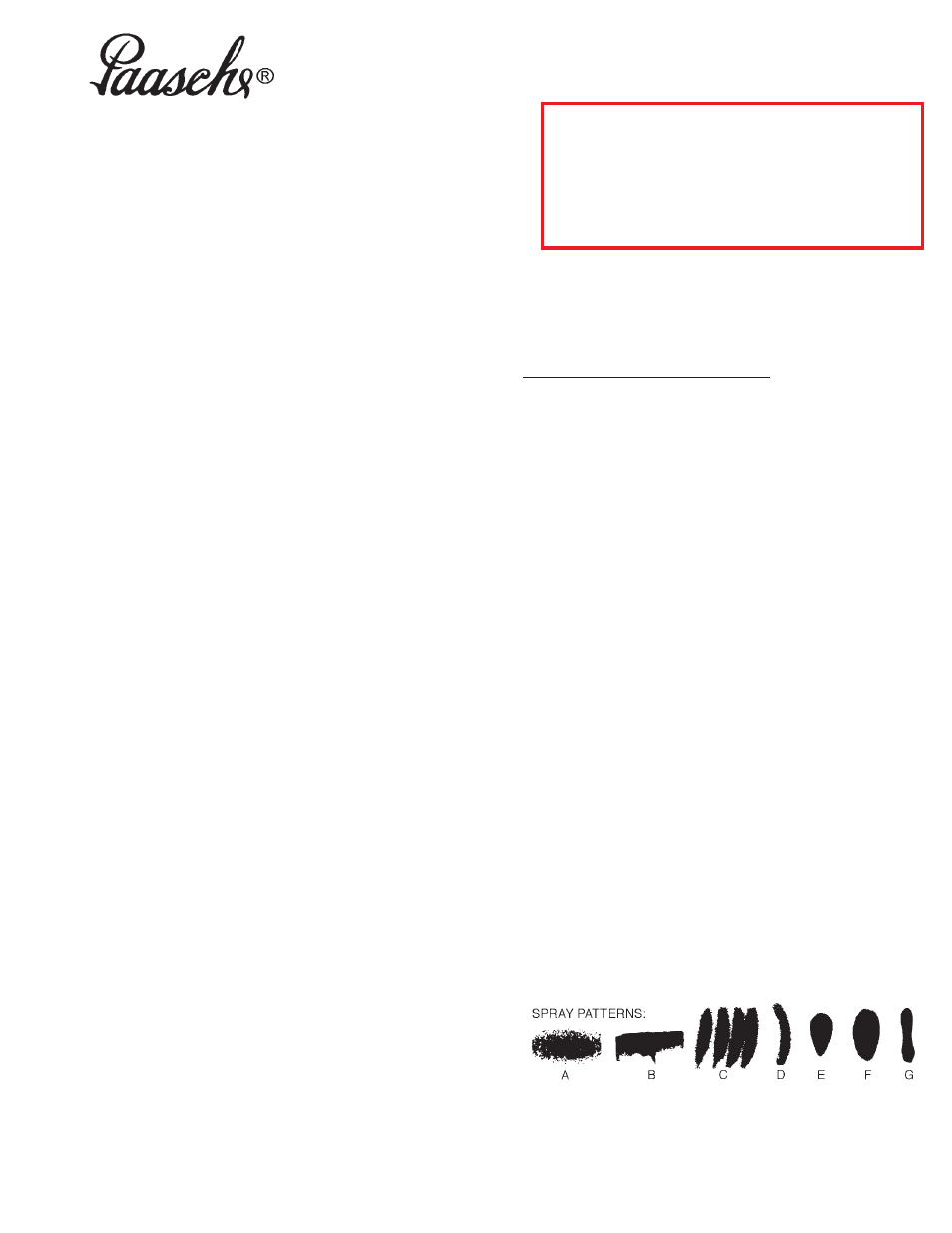

TROUBLE SHOOTING SPRAY PATTERNS:

(A) A ROUGH OR STIPPLE FINISH is due to low or restricted flow of air

pressure or too heavy materials being applied with spray gun too close

to surface.

(B) A WET OR SAGGING FINISH is due to low air pressure or restricted

flow of air, material being too thin, applied too close to the surface.

(C) A SPUTTERING SPRAY is caused by air leaking into fluid line or can

be caused by a loose fluid tip, a broken or split tip, lumpy material, a

clogged vent hole in cover of material cup, air leak at fluid pipe

attached to inside of tank cover, or a clogged paint strainer.

TO CORRECT: Tighten tip securely or replace. Strain materials and

clean strainer. Sputtering might also be caused by worn packing

washers, or worn or scored needle.

(D) AN ARCHED FAN SPRAY PATTERN is caused by dried material

accumulated in one fan port of the fan aircap distorting the pattern.

TO CORRECT: Dissolve material inside fan port with suitable solvent

applied with a small brush.

NOTE: Never use wire or sharp instruments to clean fan ports as

permanent damage to the air ports will result in destroying

uniformity of the fan pattern.

(E) UNBALANCED FAN SPRAY PATTERN, heavy on one side, may be

caused by material collecting around outside of the fluid tip and

aircap, or by a loose aircap.

TO CORRECT: Remove aircap and clean fluid tip and aircap with

solvent, dry with air pressure. Always be sure fan aircap and aircap

body is tightened securely.

(F) A HEAVY CENTER in a fan pattern is caused by insufficient air

pressure at the fan port. Rough or shady edges are also caused by

low air pressure.

TO CORRECT: Increase air line pressure.

(G) A SPLIT FAN SPRAY PATTERN heavy on each end and light in the

center, is caused by excessive air pressure.

TO CORRECT: Reduce air pressure.