Paasche Airbrush AUT User Manual

Paasche Airbrush Accessories for air

DESCRIPTION:

The AUB- Series Manual Spray Guns can be used with light to

medium consistency materials for touch-up, shading and

finishing of small parts. They can cover a range of materials to

include light lacquers, latex or corrosives. When using

Extensions, material must be pressure fed for proper

application.

AIR AND FLUID CONNECTIONS:

Air Inlet 1/4" N.P.T. (M) and Fluid Inlet 1/4" N.P.T. (M).

PACKING WASHERS are leather and treated in oil. For PTFE

Packings see parts list Page 3.

OPERATION:

1. Before using, blow out air hoses with compressed air to

remove foreign particles.

2. Connect airhose to U-49A Valve Casing for type AUT- (Thumb-

Action) Spray Gun and U-807 for type AUB-.

3. Keep connections tight, any leakage of air will impair

operation of Spray Gun and waste air pressure.

4. Siphon Cup: Attach Cup to the fluid body assembly when

1/4" N.P.T. threaded inlet is in the down position.

5. Gravity Cup: Loosen U-58 Nut and turn fluid body inlet to the

top of Spray Gun; tighten U-58. A gravity feed cup will feed

fluid approximately 30% faster than a siphon feed cup. This

permits detail work with head of spray gun close to the work

surface (cup on top) .

6. Pressure Tank: When fluid hose is coupled directly to fluid inlet

of Spray Gun, HA-1/4 Fluid Hose with HAC-1/4 and HAC-1/4-3/8

Couplings should be ordered. Attach HAC-1/4-3/8 Coupling to

fluid outlet of tank.

7. To control Fluid: AUB- (Bottom Air Inlet) adjust 200-17 Fluid

Knob. AUT- (Thumb-Action) adjust the U-1816 Adjusting Screw.

8. A fan is used for broad patterns. Stipple effects can be

obtained by reducing atomizing pressure until dots are

produced.

9. A round pattern is used for narrow work, stippling, stenciling

and shading.

10.As width of pattern increases flow of material must be

increased proportionately to obtain fast coverage of larger

areas. By proper adjustment, patterns up to 6", may be

obtained with size 3 Spray Head Components.

11. Grip Spray Gun like a pistol placing two fingers on the trigger.

The first one-quarter pull releases air only, this can be used

for cleaning and dusting surfaces before painting. Continued

pull on the trigger opens the fluid needle and a full wide fan

pattern can be achieved.

INSTRUCTIONS & PARTS LIST AUB & AUT-8/31/2011

Supersedes Instructions & Parts List AUB & AUT-12/8/2010

WARNING: Spray materials may be harmful if inhaled or

allowed to come into contact with the skin or eyes. Consult

the product label and Material Safety Data Sheet supplied

for the spray material. Follow all safety precautions.

CAUTION: Well Ventilated Area Required to remove

fumes, dust or overspray. Secure airhose and fluid

hose wrench tight for safety and to prevent leaks.

M a x i m u m A i r P r e s s u r e 1 0 0 P . S . I .

M a x i m u m F l u i d P r e s s u r e 4 5 P. S . I .

12. Begin painting with as light a coat as possible. Take long

strokes from side to side, releasing trigger at the end of each

stroke. Check to make sure each stroke meets without much

overlapping which can cause material to run. For general

painting hold the Spray Gun with head approximately 2" to 6"

from the surface. For narrow lines, approximately 1" to 2",

use a short trigger pull and hold Spray Gun close to surface.

To obtain a wider spray, pull trigger back while gradually

drawing the head of the gun away from surface until desired

width of pattern is reached.

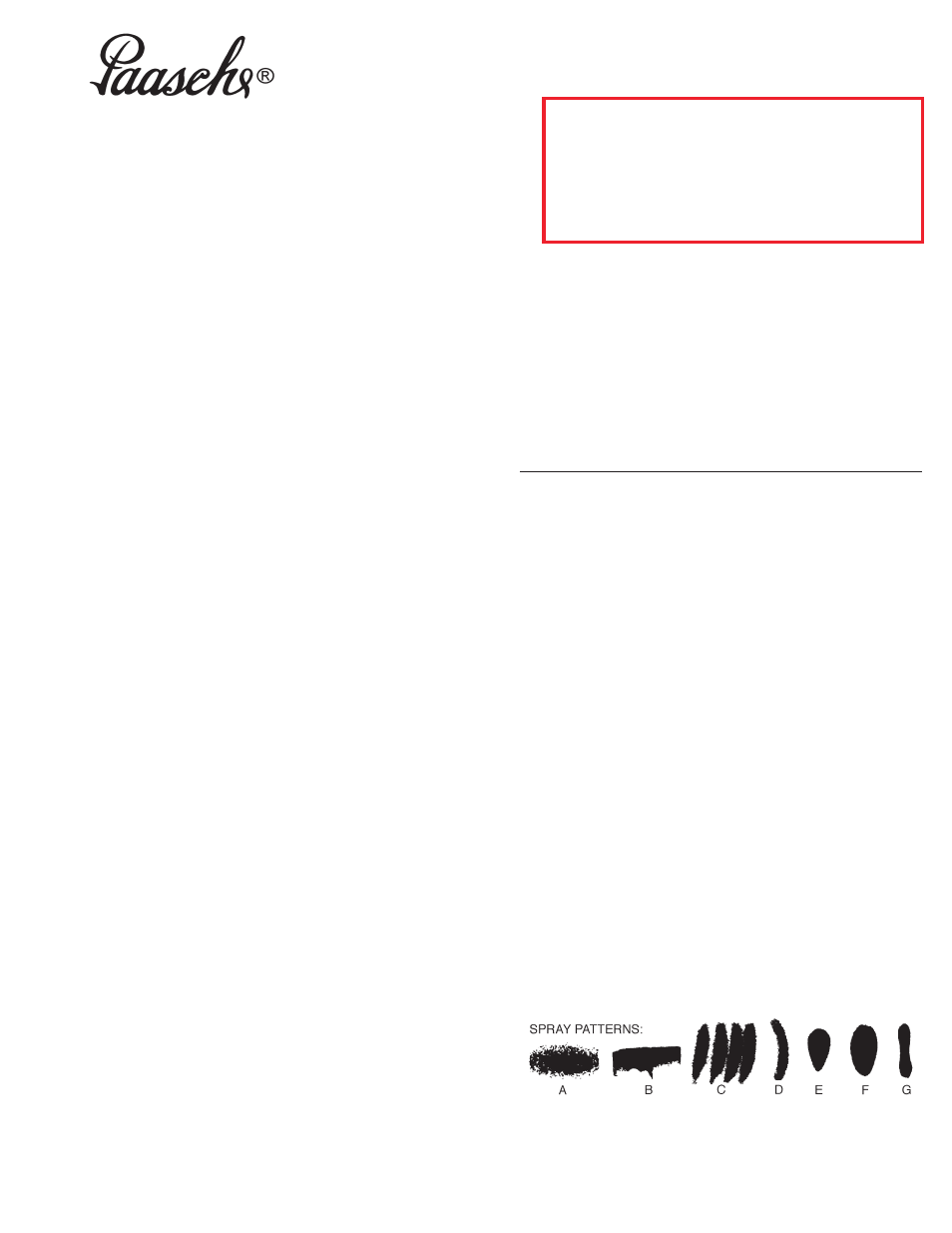

TROUBLE SHOOTING SPRAY PATTERNS:

A.

A ROUGH OR STIPPLE FINISH is due to low or restricted flow of air

pressure or heavy materials being applied with the spray gun too

close to surface.

B.

A WET OR SAGGING FINISH is due to low air pressure or restricted

flow of air, material being too thin or applied too close to the surface.

C.

A SPUTTERING SPRAY is caused by air leaking into fluid line or can

be caused by a loose fluid tip, a broken or split tip, lumpy material, a

clogged vent hole in cover of material cup, air leak at fluid pipe

attached to inside of tank cover, or a clogged paint strainer.

TO CORRECT: Tighten tip securely or replace. Strain material and

clean strainer. Sputtering might also be caused by worn packing

washers, or worn or scored needle.

D. AN ARCHED FAN SPRAY PATTERN is caused by dried material

accumulated in one fan port of the multiplehead, distorting the

pattern.

TO CORRECT: Dissolve material inside fan port with suitable

water/solvent applied with a small brush.

Never use wire or sharp instruments to clean fan ports as

permanent damage to the air ports will result in altering

uniformity of the fan spray pattern.

E.

UNBALANCED FAN SPRAY PATTERN, heavy on one side, may be

caused by material collecting around outside of the fluid tip and

aircap, or by a loose aircap.

TO CORRECT: Remove aircap and clean fluid tip and aircap with

water/solvent, dry with air pressure. Always be sure fan aircap and

aircap body is tightened securely.

F.

A HEAVY CENTER in a fan pattern is caused by insufficient air

pressure at the fan port. Rough or shady edges are also caused by

low air pressure.

TO CORRECT: Increase air line pressure.

G.

A SPLIT FAN SPRAY PATTERN, heavy on each end and light in

the center, is caused by excessive air pressure.

TO CORRECT: Reduce air pressure.

Printed in the U.S.A.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: [email protected]

AUB- (Bottom Air Inlet)

AUT- (Thumb Action)

Manual Spray Guns

OPERATING INSTRUCTIONS AND REPLACEMENT PARTS