Paasche Airbrush 62-PL User Manual

3 oz. siphon sprayers

WARNING: Spray materials may be harmful if inhaled or

allowed to come into contact with the skin or eyes. Consult

the product label and Material Safety Data Sheet supplied

for the spray material. Follow all Safety precautions.

CAUTION: Well Ventilated Area required to remove fumes,

dust or overspray. Secure airhose to Sprayer for safety and

to prevent air leaks. Keep your 62 Sprayer clean.

M a x i m u m A i r P r e s s u r e 6 0 P . S . I .

62-1-3 and 62-2-3

3 oz. Siphon Sprayers

OPERATING INSTRUCTIONS & REPLACEMENT PARTS

INTRODUCTION:

62-Sprayers are ideal for use in art studios and hobby

workshops, also for window trimmers, auto finishers, furniture

finishers and general touch-up work. Department stores of

every type find the 62-Sprayers excellent time savers for touch-

up and color application of window displays. It’s simple design

makes it easy to operate, no special adjustments are needed.

The 62-Sprayer sprays medium consistency lacquer, enamel,

varnish stain, light oil, dye, liquid wax, automotive paint, fixative,

etc. Bakers, Confectioners and Candy Makers use it to apply

powder, sugar and fine granules.

NOTE: When spraying with acrylics, with any model or make

airbrush or sprayer, periodic cleaning is necessary to prevent

build-up.

ALWAYS follow mixing and atomizing pressure instructions

listed on label of material being sprayed.

RECOMMENDED AIR PRESSURE:

Any air compressor 1/6 HP or larger is an ideal companion for the

62-Sprayer. Paasche’s D200 Compressor is capable of operating

this sprayer at pressures up to 24 psi.

OPERATION:

1. Before filling bottle, mix material thoroughly and strain

through cheese cloth or screen to remove any lumps of

material.

2. Blow out air hose before attaching to sprayer to clear

hose line of foreign matter. Attach air hose to air inlet at

bottom of handle.

3. Air pressure can be from 1 to 40 p.s.i., depending on type of

material being sprayed.

a. For stipple effects use 10 to 15 p.s.i. air pressure.

b. For Light fluid applications (Inks, Dyes, & Watercolors)

use 20 to 25 p.s.i. air pressure.

c. For Medium fluid applications (Varnish, Lacquers, Acrylics

or Enamels) reduced to free flowing consistency use 25 to

35 p.s.i. air pressure.

d. For Heavier fluid (Automotive Enamels, Acrylics and

Ceramic Glazes) use a Minimum of 40 p.s.i. air pressure.

CAUTION: DO NOT use Air Pressure in excess of 60 p.s.i.

4. Practice pressing thumb button valve to stop and start

spraying action.

a. For best results nozzle should be 3 to 6 inches from the

working surface.

b. Always keep sprayer in motion throughout entire spraying

stroke to prevent dripping and sagging.

c. Start and stop spray before and after each stroke to

prevent sags, runs and piling of material at the end of

stroke.

5. When finished spraying, pour unused fluid material back into

container.

a. Rinse 62-17P 3 oz. (89cc) Plastic Bottle and clean VF-39

Color Tube with solvent before fluid hardens.

b. For cleaning clogged parts, soak in solvent for a long

enough period of time to unclog hardened residue.

c. When changing color either by using the same bottle or

another bottle always clean bottle and color tube before

spraying new color. Test a spray pattern on paper to clear

sprayer of solvent or previously sprayed material.

62-1-3

3 oz. Sprayer for light fluids and fine Atomization

62-2-3

3 oz. Sprayer for Medium to Heavy fluids and faster Atomization.

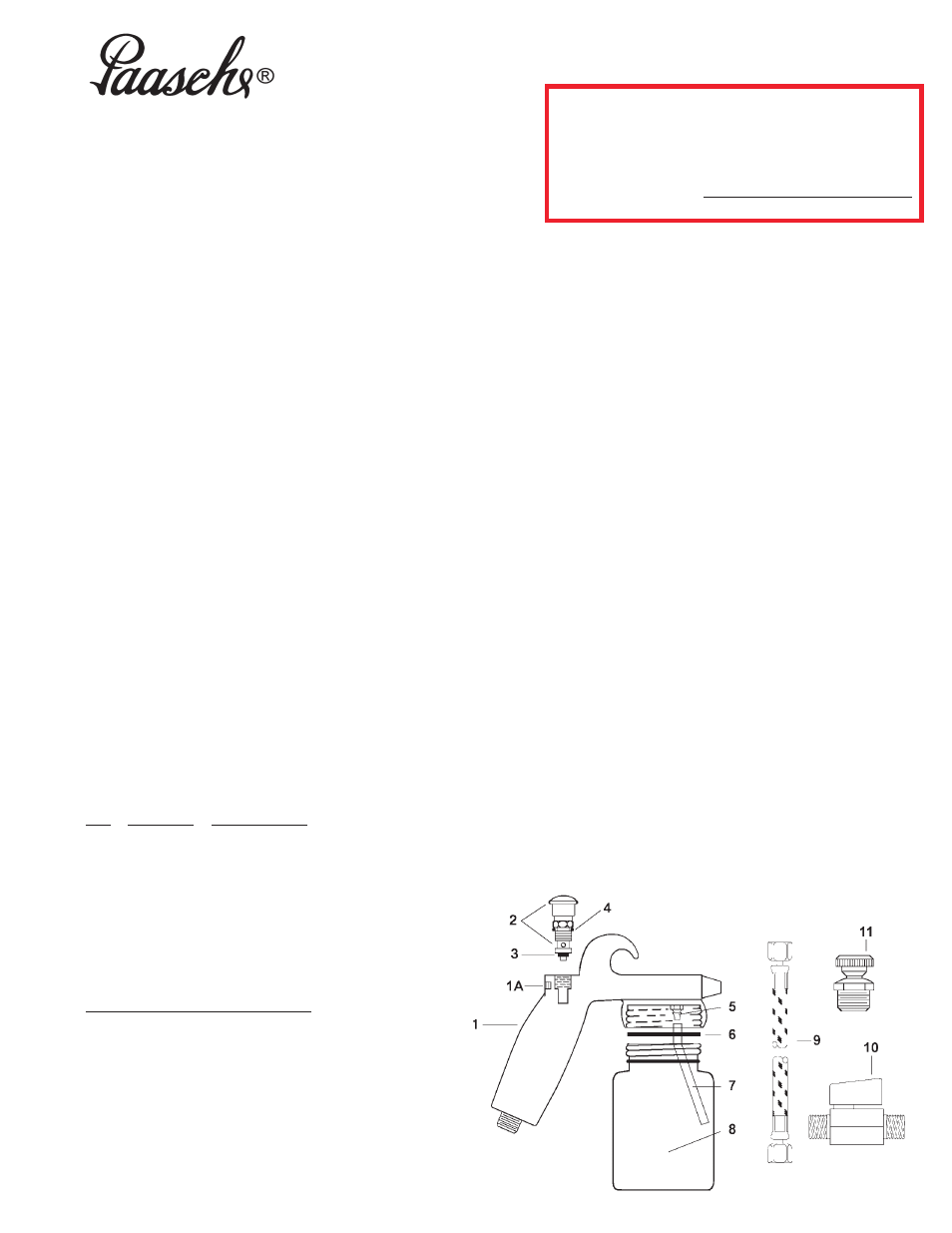

NO.

PART NO.

DESCRIPTION

1.

62-1

Sprayer Body or -

62-2

Sprayer Body

1A.

200-11

Set Screw

2.

DA-30

Valve

3.

DA-23

Valve Seat Washer

4.

AE-6

“O” Ring

5.

200-32

Threaded Barb

6.

3-JG

Gasket

7.

VF-39

2.875" lg. Plastic Color Tube

8.

62-17P

3 oz. Plastic Bottle (89cc)

ACCESSORIES - NOT INCLUDED:

9.

HL-3/16-8

Air Hose w/Couplings

• HLC-3/16-1/4 Couplings at both ends.

10.

HF-1/4

Valve Assembly

11.

DB-32

Tire Chuck

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: [email protected]

INSTRUCTIONS AND PARTS LIST 8/31/2011

Supersedes Instructions & Parts List 62-5/2008

Printed in the U.S.A.