Paasche Airbrush A-JU-PL User Manual

Page 4

Page 4

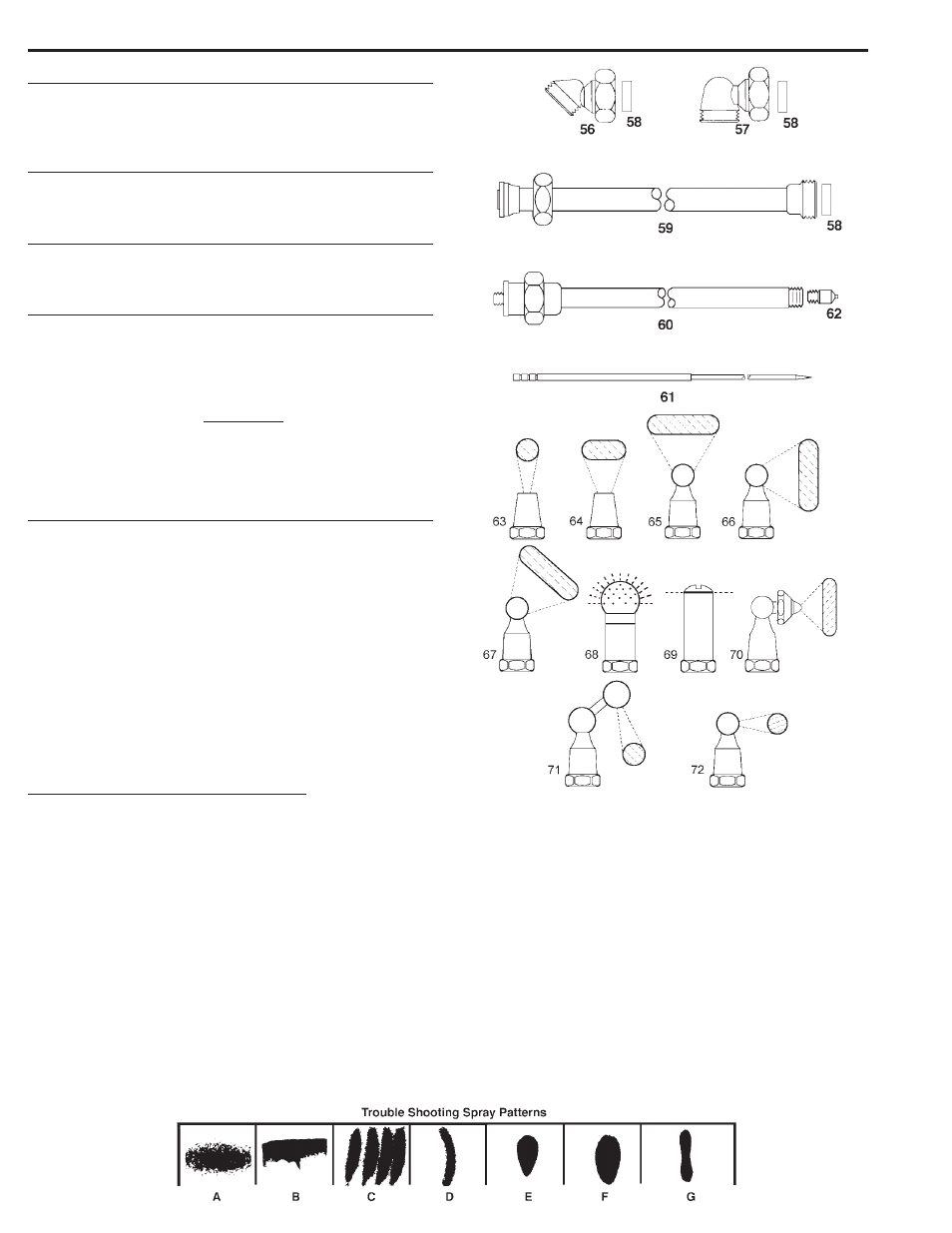

Paasche A-JU Spray Gun Accessories

Accessories for A-JU Automatic Spray Gun

56. AEN-45

45° Elbow

57. AEN-90

90° Elbow

58. AN

Nylon Washer

AE- Extensions (ANF- and AR- Heads only)

• Length Sizes: -3, -6, -12, -18, -24

59. AE-

Extension L/Needle (Select Size)

Ax- Stainless Steel Extensions (Ax- Aircaps only)

• Length Sizes: -3, -6, -12, -18, -24, -36, -48

60. Ax-

St. St. Extension L/Needle (Select Size)

A-AJ- Extension Needles (AE- & Ax- Extensions)

• Length Sizes: -3, -6, -12, -18, -24, -36, -48

61. A-AJ-

St. St. Extension Needle (Select Size)

Q All Ax Aircaps must use a Pressure Feed

Cup or Pressure Tank to feed material being

sprayed. Always adjust atomizing air pressure

higher than fluid air pressure.

Ax- Style Tips and Aircaps (Ax- Extensions Only)

62. Ax-1

Tip

63. AxR

Aircap External Round Pattern

64. AxF

Aircap External Fan Pattern

65. AxIF

Aircap Internal Fan Pattern

66. AxIF-90

Aircap Internal Fan Pattern

67. AxIF-45

Aircap Internal Fan Pattern

68. AxIB

Aircap Spherical Pattern

69. AxI-360

Aircap Radial Pattern

70. AxIF-90A

Aircap Internal Fan Pattern

71. AxIR-15

Aircap Internal Round Pattern

72. AxIR-90

Aircap Internal Round Pattern

TROUBLE SHOOTING SPRAY PATTERNS:

(A) A ROUGH OR STIPPLE FINISH is due to low or restricted flow

of air pressure or too heavy materials being applied with spray

gun too close to surface.

(B) A WET OR SAGGING FINISH is due to low air pressure or

restricted flow of air, material being too thin, applied too close

to the surface.

(C) A SPUTTERING SPRAY is caused by air leaking into fluid line

or can be caused by a loose fluid tip, a broken or split tip,

lumpy material, a clogged vent hole in cover of material cup,

air leak at fluid pipe attached to inside of tank cover, or a

clogged paint strainer.

TO CORRECT: Tighten tip securely or replace. Strain

materials and clean strainer. Sputtering might also be caused

by worn packing washers, or worn or scored needle.

(D) AN ARCHED FAN SPRAY PATTERN is caused by dried

material accumulated in one fan port of the multiplehead

distorting the pattern.

TO CORRECT: Dissolve material inside fan port with suitable

solvent applied with a small brush.

NOTE: Never use wire or sharp instruments to clean fan

ports as permanent damage to the air ports will result in

destroying uniformity of the fan pattern.

(E) UNBALANCED FAN SPRAY PATTERN, heavy on one side,

may be caused by material collecting around outside of the

fluid tip and aircap, or by a loose aircap.

TO CORRECT: Remove aircap and clean fluid tip and aircap

with solvent, dry with air pressure. Always be sure fan aircap

and aircap body is tightened securely.

(F) A HEAVY CENTER in a fan pattern is caused by insufficient air

pressure at the fan port. Rough or shady edges are also

caused by low air pressure.

TO CORRECT: Increase air line pressure.

(G) A SPLIT FAN SPRAY PATTERN heavy on each end and light

in the center, is caused by excessive air pressure.

TO CORRECT: Reduce air pressure.