Operation, Warning safety precautions – Lincoln Electric IM10038 POWER WAVE C300CE User Manual

Page 21

B-1

OPERATION

POWER WAVE® C300 CE

B-1

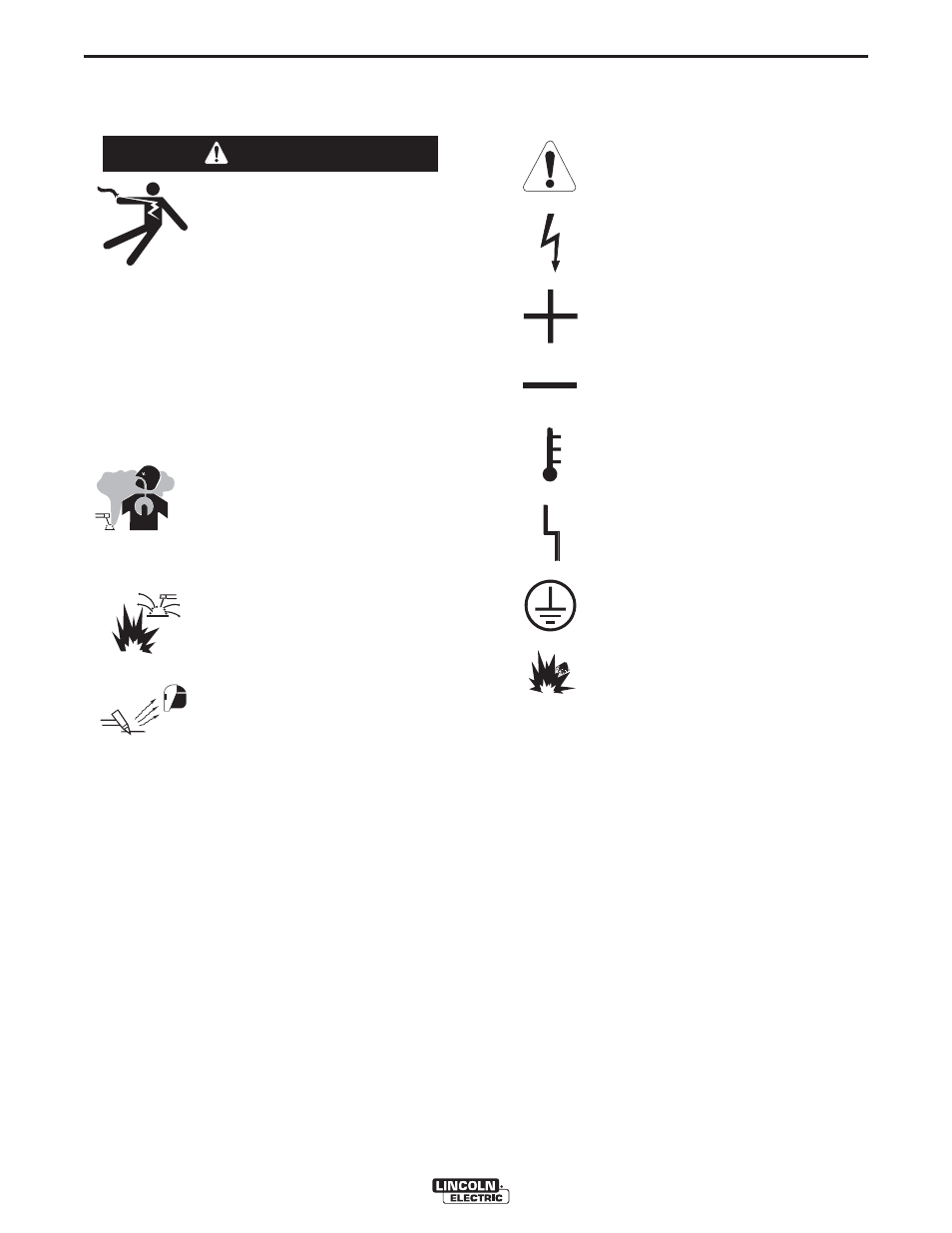

• ELECTRIC SHOCK CAN KILL.

Unless using COLD FEED fea-

ture, when feeding with gun trig-

ger, the electrode and drive

mechanism are always electri-

cally energized and could

remain energized several sec-

onds after the welding ceases.

• Do not touch electrically live part or electrode

with skin or wet clothing.

• Insulate yourself from work and ground.

• Always wear dry insulating gloves.

• Do not operate with covers, panels or guards

removed or open.

---------------------------------------------------------------------

• FUMES AND GASSES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

---------------------------------------------------------------------

• WELDING SPARKS can cause

fire or explosion.

• Keep flammable material away.

---------------------------------------------------------------------

ARC RAYS can burn.

• Wear eye, ear and body protec-

tion.

---------------------------------------------------------------------

SEE ADDITIONAL WARNING INFORMATION

UNDER ARC WELDING SAFETY PRECAUTIONS

AND IN THE FRONT OF THIS OPERATING MAN-

UAL.

---------------------------------------------------------------------

WARNING

SAFETY PRECAUTIONS

READ AND UNDERSTAND ENTIRE SECTION

BEFORE OPERATING MACHINE.

POSITIVE OUTPUT

NEGATIVE OUTPUT

STATUS

PROTECTIVE

GROUND

EXPLOSION

WARNING OR

CAUTION

GRAPHIC SYMBOLS THAT APPEAR ON

THIS MACHINE OR IN THIS MANUAL

HIGH TEMPERATURE

DANGEROUS

VOLTAGE

POWER-UP SEQUENCE

When the POWER WAVE® C300 CE is powered it

can take as long as 30 seconds for the machine to be

ready to weld. During this time period the user inter-

face will not be active.

DUTY CYCLE

The POWER WAVE® C300 CE is rated at 250 amps

at 26.5 volts with a 100% duty cycle. It is further rated

to provide 300 amps at 29 volts with a 40% duty cycle.

The duty cycle is based on a ten-minute period. A

40% duty cycle represents 4 minutes of welding and 6

minutes of idling in a ten-minute period.