Installation, Feeding electrode and brake adjustment – Lincoln Electric IM10038 POWER WAVE C300CE User Manual

Page 19

A-9

INSTALLATION

POWER WAVE® C300 CE

A-9

FEEDING ELECTRODE AND BRAKE

ADJUSTMENT

DRIVE ROLL PRESSURE SETTING

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the weld-

ing power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When feeding with the gun trigger, unless

“COLD FEED” trigger mode is selected, the elec-

trode and drive mechanism are always “HOT” to

work and ground and could remain “HOT” sev-

eral seconds after the gun trigger is released.

• Do not operate with covers, panels or guards

removed or open

• Only qualified personnel should perform mainte-

nance work.

------------------------------------------------------------------------

The POWER WAVE® C300 CEʼs optimum drive roll

pressure varies with type of wire, surface condition,

lubrication, and hardness. Too much pressure could

cause birdnesting”, but too little pressure could cause

wire feed slippage with load and/or acceleration. The

optimum drive roll setting can be determined as fol-

lows:

1. Turn the Reel or spool until the free end of the

electrode is accessible.

2. While tightly holding the electrode, cut off the bent

end and straighten the first 6" (150 mm). Cut off

the first 1" (25 mm). (If the electrode is not properly

straightened, it may not feed or may jam causing a

"birdnest".)

3. Insert the free end through the incoming guide

tube.

4. Press the Cold Inch key and push the electrode

into the drive roll.

5. Feed the electrode through the gun.

6. Adjust the brake tension with the thumbscrew on

the spindle hub, until the reel turns freely but with

little or no overrun when wire feeding is stopped.

Do not over tighten.

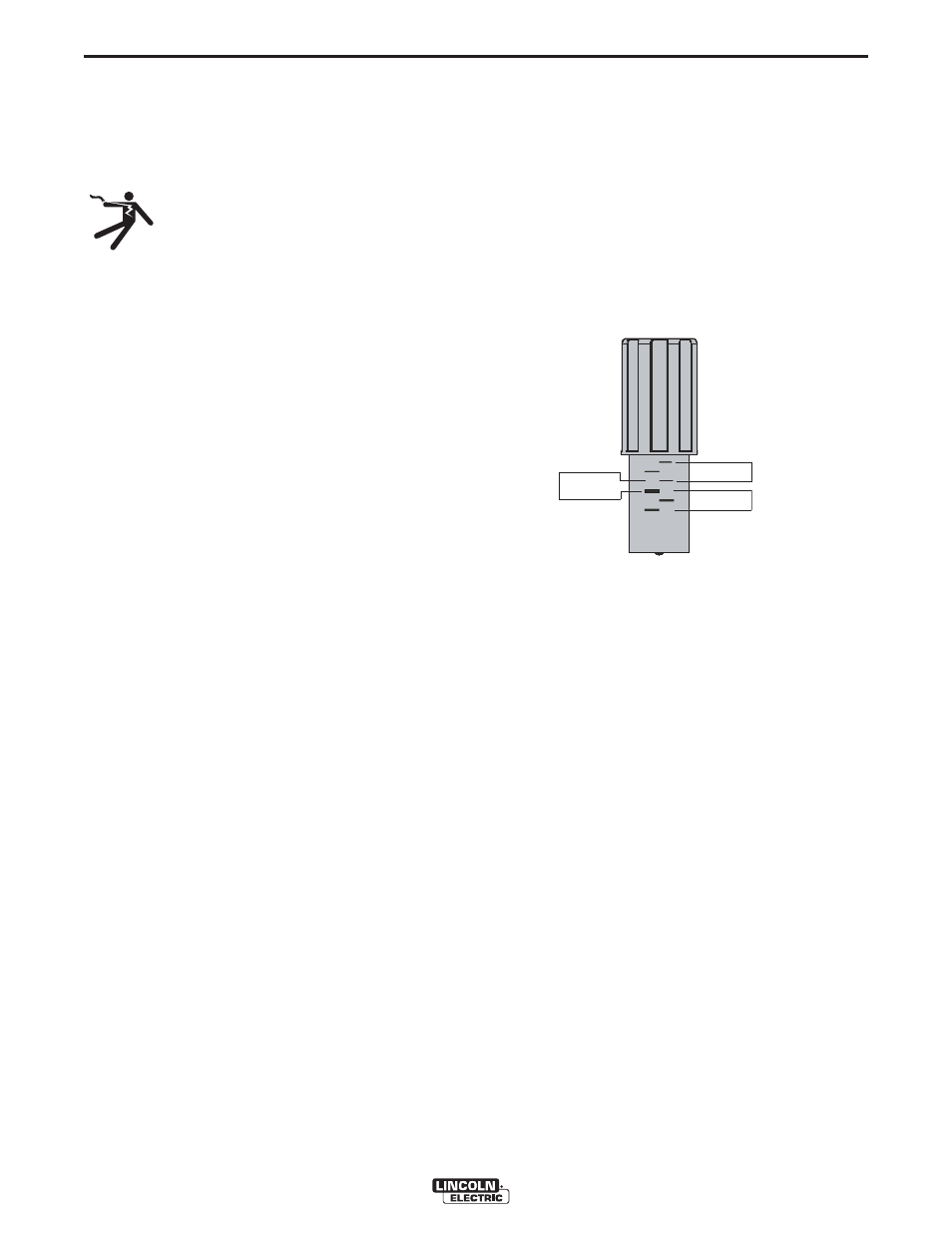

PRESSURE ARM ADJUSTMENT

The pressure arm controls the amount of force the drive

rolls exert on the wire. Proper adjustment of pressure

arm gives the best welding performance.

Set the pressure arm as follows (See Figure A.6):

Aluminum wires

between 1 and 3

Cored wires

between 3 and 4

Steel, Stainless wires

between 4 and 6

FIGURE A.6

ALUMINUM

FLUX CORE

ARC WELDING

GAS METAL

ARC WELDING

6

1

3

2

5

4

Aluminum wires

Cored wires

Steel, Stainless wires