Maintenance and inspection -9, Maintenance and inspection – XLT Hitachi X200 User Manual

Page 228

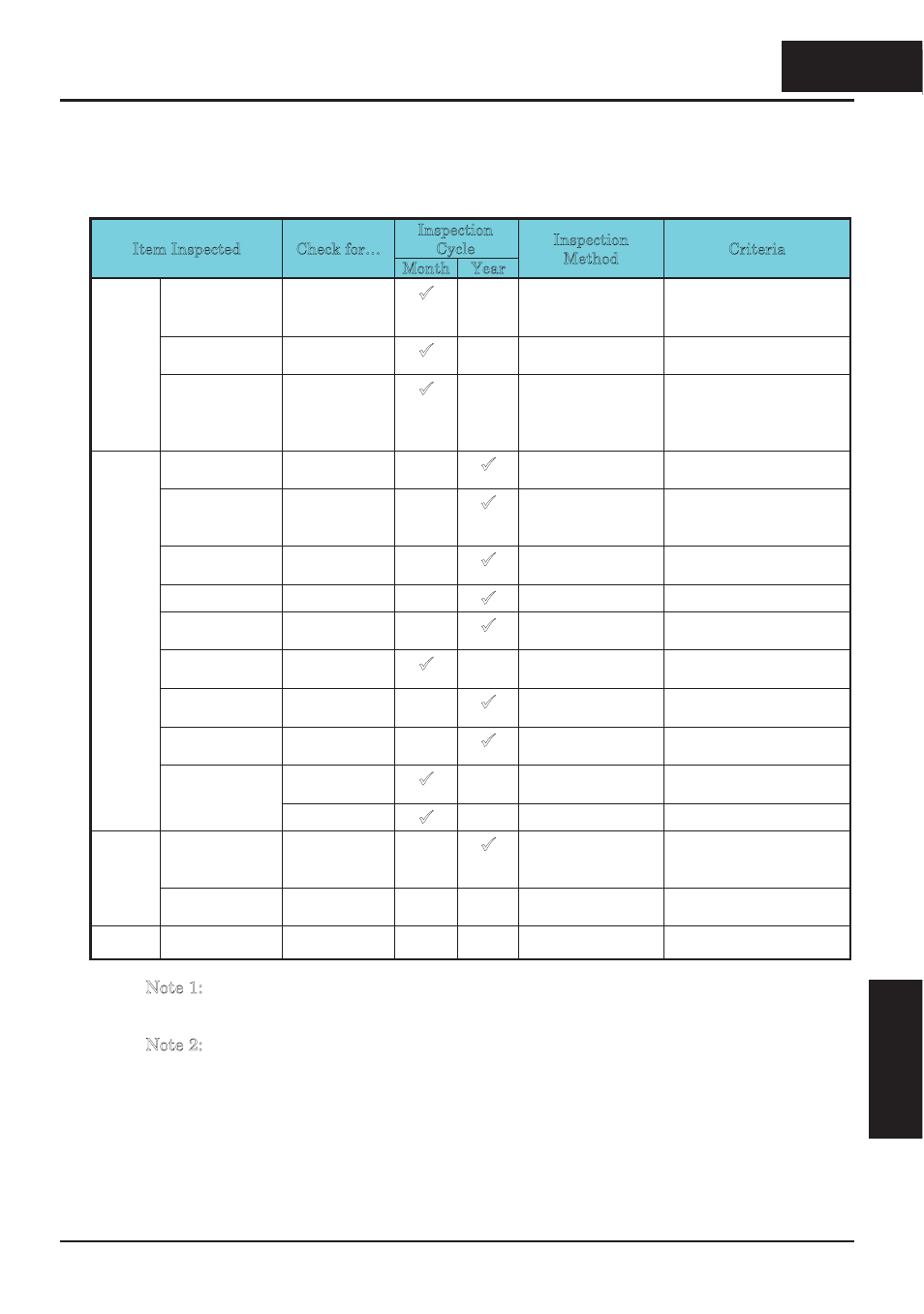

Maintenance and Inspection

Monthly and Yearly Inspection Chart

Inspection

Cycle

Item Inspected

Check for…

Month

Year

Inspection

Method

Criteria

Ambient

environment

Extreme

temperatures

& humidity

9

Thermometer,

hygrometer

Ambient temperature

between – 10 to 40

qC,

non-condensing

Major devices

Abnormal

noise & vib.

9

Visual and aural

Stable environment for

electronic controls

Overall

Power supply

voltage

Voltage

tolerance

9

Digital volt meter,

measure between

inverter terminals

[L1], [L2], [L3]

200V class:

200 to 240V 50/60 Hz

400V class:

380 to 460V 50/60 Hz

Ground

Insulation

Adequate

resistance

9

Digital volt meter,

GND to terminals

5 M

: or greater

Mounting

No loose

screws

9

Torque wrench

M3: 0.5 – 0.6 Nm

M4: 0.98 – 1.3 Nm

M5: 1.5 – 2.0 Nm

Components

Overheating

9

Thermal trip

events

No trip events

Housing

Dirt, dust

9

Visual

No abnormalities

Terminal block Secure

connections

9

Visual

No abnormalities

Smoothing

capacitors

Leaking,

swelling

9

Visual

No abnormalities

Relay(s)

Chattering

9

Aural

Single click when

switching ON or OFF

Resistors

Cracks or

discoloring

9

Visual

Check Ohms of optional

braking res.

Noise

9

Power down,

manually rotate

Rotation must be

smooth

Main

circuit

Cooling fan

Dust

9

Visual

Vacuum to clean

Overall

No odor,

discoloring,

corrosion

9

Visual

No abnormalities

Control

circuit

Capacitor

No leaks or

deformation

Visual

Undistorted appearance

Display LEDs

Legibility

Visual

All LED segments work

Note 1:

The life of a capacitor is affected by the ambient temperature. See

“Capacitor

Life Curve” on page 6–11

.

Note 2:

The inverter must be cleaned periodically. If dust accumulates on the fan and

heat sink, it can cause overheating of the inverter.

6

9

T

roubleshooting and

Maintenanc

e

6

−9

T

roubleshooting and

Maintenance