Electronic thermal overload alarm setting – XLT Hitachi X200 User Manual

Page 117

Electronic Thermal Overload Alarm Setting

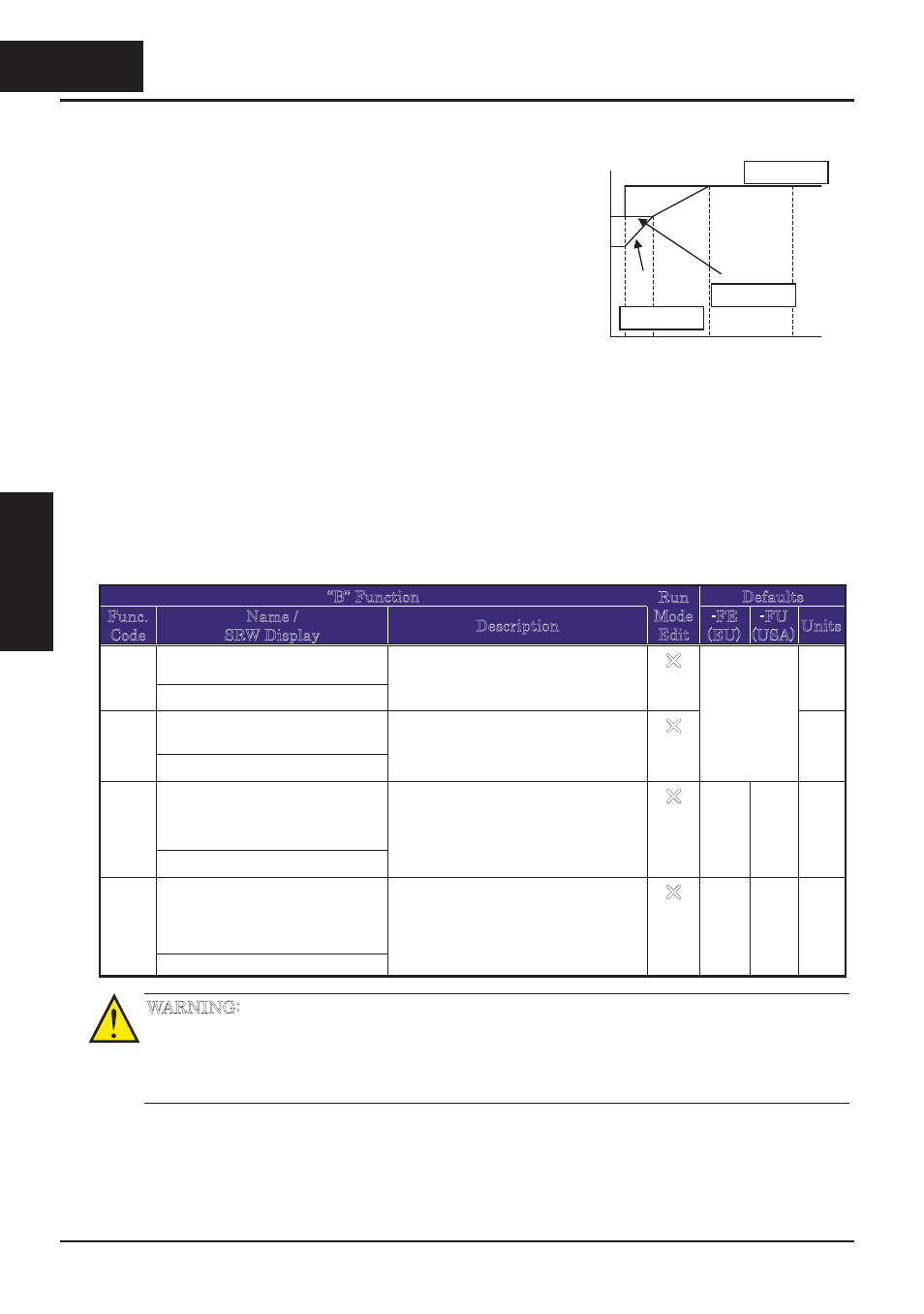

The thermal overload detection protects the

inverter and motor from overheating due to an

excessive load. It uses a current/inverse time

curve to determine the trip point.

First, use B013 to select the torque characteristic

that matches your load. This allows the inverter

to utilize the best thermal overload characteristic

for your application.

The torque developed in a motor is directly

proportional to the current in the windings,

which is also related to the heat generated (and

temperature, over time).

Therefore, you must set the thermal overload threshold in terms of current (amperes)

for parameter B012. The range is 20% to 120% of the rated current for each inverter

model. If the current exceeds the level you specify, the inverter will trip and log an event

(error E05) in the history table. The inverter turns the motor output OFF when tripped.

Separate settings are available for the second motor (if applicable) as shown in the

following table.

“B” Function

Defaults

Func.

Code

Name /

SRW Display

Description

Run

Mode

Edit

-FE

(EU)

-FU

(USA)

Units

Level of electronic thermal

setting

B012

E-THM LVL

001.60A

Set a level between 20% and

100% for the rated inverter

current.

U

A

Level of electronic thermal

setting, 2nd motor

B212

2ETHM LVL

001.60A

Set a level between 20% and

100% for the rated inverter

current.

U

Rated

current for

each inverter

model *1

A

Electronic thermal

characteristic

B013

E-THM CHAR

CRT

Select from three curves, option

codes:

00

}Reduced torque 1

01

}Constant torque

02

}Reduced torque 2

U

01

01

Electronic thermal

characteristic, 2nd motor

B213

2ETHM CHAR

CRT

Select from three curves, option

codes:

00

}Reduced torque 1

01

}Constant torque

02

}Reduced torque 2

U

01

01

WARNING: When parameter B012, level of electronic thermal setting, is set to motor

FLA rating (Full Load Ampere nameplate rating), the inverter provides solid state

motor overload protection at 115% of motor FLA or equivalent. If parameter B012

exceeds the motor FLA rating, the motor may overheat and be damaged. Parameter

B012, level of electronic thermal setting, is a variable parameter.

3

34

Config

uri

ng Driv

e

Parameters

Torque

100%

120

60

20

5

80%

60%

0

Hz

Constant torque

Reduced

torque2

B013 = 01

B013 = 02

Output frequency

Reduced

torque1

B013 = 00

3

−34

&RQ¿JXULQJ'ULYH

Parameters