Warning – WEATHER GUARD 239 User Manual

Page 2

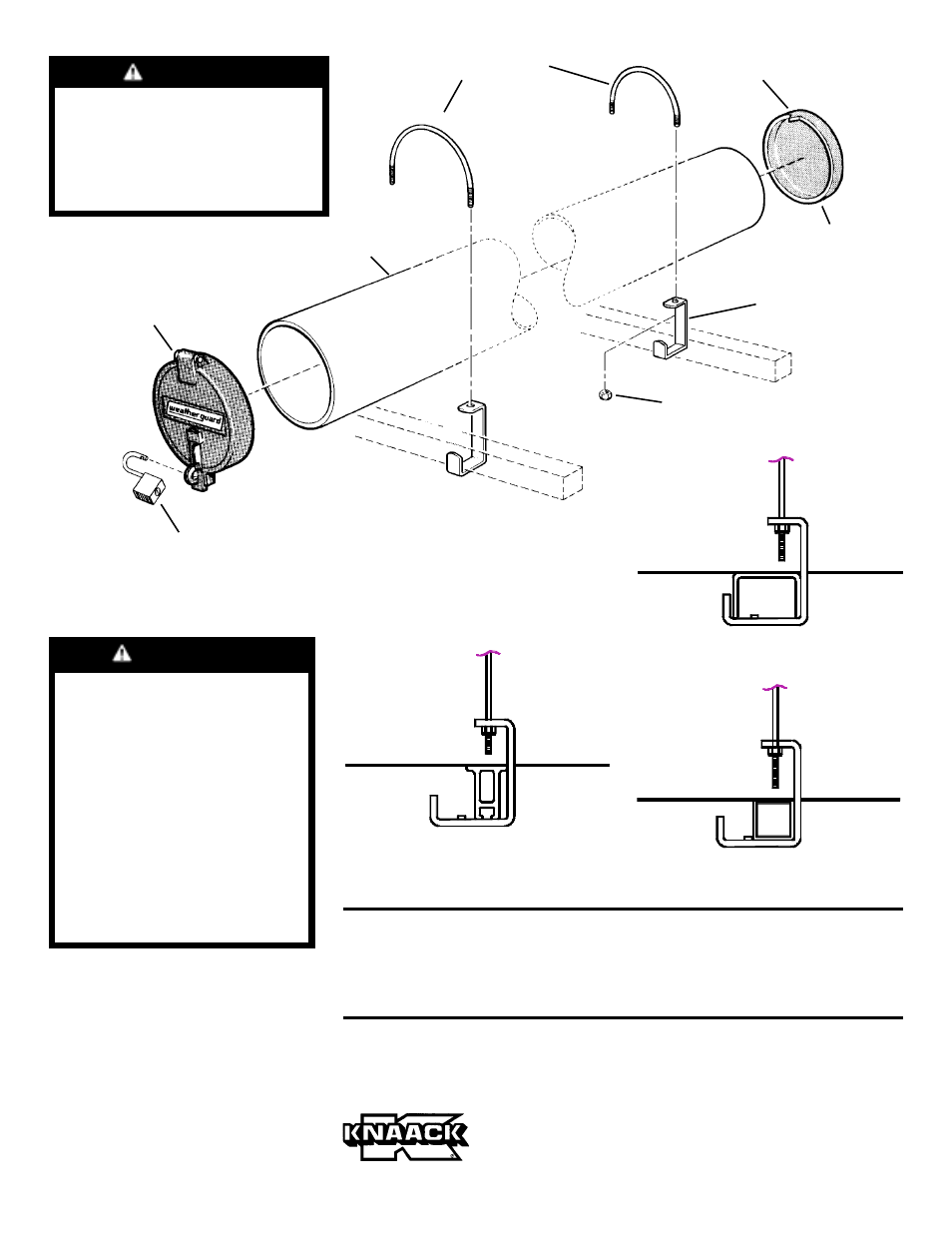

7. Place the Conduit Carrier in position

on your ladder rack. Install the "U"

Clamps and Clamp Brackets (

see Fig-

ure 1.). (See Figures 2a, 2b and 2c for

installation of "U" Clamps and Clamp

Brackets for your crossmember). Be-

fore tightening the nuts, make sure the

conduit carrier is correctly positioned

and the rear door latch is pointing

down as shown in the illustration.

WARNING

Rear end cap door must be pad-

locked during transit to prevent

accidental spillage of contents,

which could cause serious per-

sonal injury or property damage.

If you have any questions, please give us a call. Call Toll Free 1-800-456-7865

Weather Guard® products are protected by one or more of the following patents or trademarks:

U.S. - 842268, 1661625, 1663369; Canada - 282725; U.K. - 1400720; other patents pending.

KNAACK MANUFACTURING COMPANY

420 E. TERRA COTTA AVENUE

CRYSTAL LAKE, ILLINOIS, 60014 - 815-459-6020

© 1993 Knaack Manufacturing Company

- NOTICE -

Any modification or unintended use of this product shall immediately void

all manufacturers warranties. Manufacturer disclaims all liability for injuries

to persons or property resulting from any modification to, or unintended

use of this product.

Rear End Cap

p/n 7073

#12-24 Nylon Lock Nut

(black dichromate)

(4 places)

Clamp Bracket

p/n 20-2390

Front Cap

p/n 21-1015

Triangular

Tab

U-Clamps

p/n 21-1017

(2 places)

PVC Pipe

Padlock

(customer supplied)

Figure 1. Assembly and Installation

on a square shaped crossmember

Figure 2a. Installation on a 211

aluminum crossmember

WARNING

Allow at least 15 minutes for

cement cure time before han-

dling, and we strongly sug-

gest a 24 hour full-cure time

before loading any materials.

If assembled Conduit Carrier

is used before the 24 hour

cure time, the material in the

conduit carrier could push

the end caps out and spillage

of material could occur

causing serious injury to

persons and property.

Figure 2b. Installation on a channel

shaped crossmember

Figure 2c. Installation on a square

shaped crossmember