Mounting anti-rotation, See anti-roatation examples on pages 8-14 – Warner Electric TG-2000 MagStop Clutch_Brake User Manual

Page 6

6

Warner Electric • 800-825-9050

P-1177 • 819-0457

If the field is bolted rigidly

or if its axial movement is restricted, the

bearing in the field assembly will be

improperly loaded and may fail. Use only

factory installed anti-rotation device.

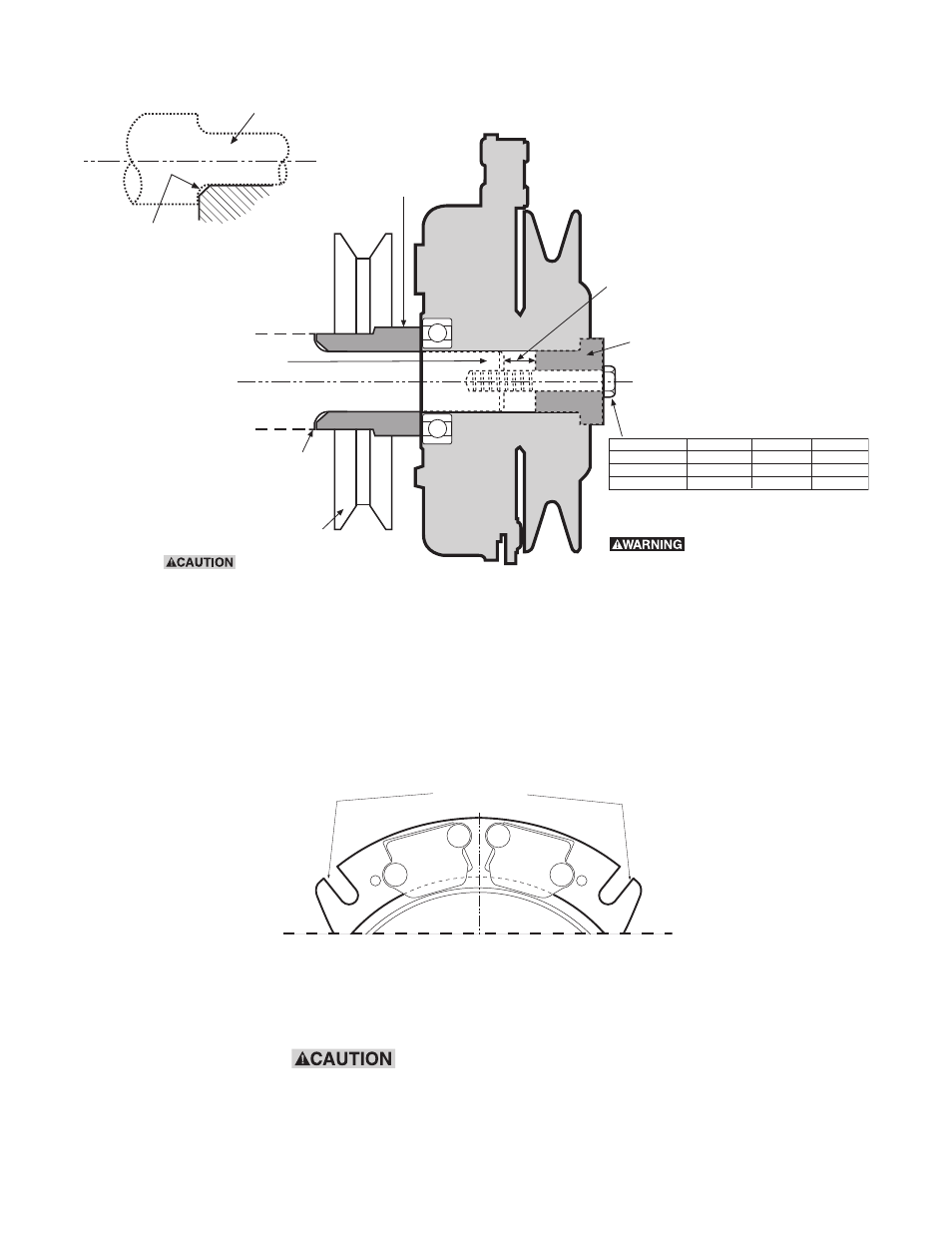

Figure 3

Typical Engine Installation with Ground Drive Pulley

Figure 4

Shaft

Shoulder

Ground

Drive

Pulley

Shaft end and

D-drive

spacer must

not touch

D-drive Spacer

Engine Shaft

Failure to torque bolt

to requirements will

degrade clamping and

can allow the clutch to

separate from the

shaft, causing risk of

personal injury.

Thread size

Torque ft.lb. Torque N-m

3/8-24" UNF

40-45 ft.lb. 54-61 N-m

7/16-20" UNF

50-55 ft.lb. 67-75 N-m

M 10 X 1.50

40-45 ft.lb. 54-61 N-m

Ground drive pulley or spacer

must be chamfered to clear this

radius on the engine shaft

shoulder.

Shaft

Ground Drive Spacer

(or spacer if no ground

round

drive used)

Always bottom the clutch against a

flat surface; never against radius.

Note:

Must have faces parallel to each other

(within .003") and be perpendicular

to the bore.

Note: All values are for dry (unlubricated) plated bolts,

please consult fastener manufacturer if any type of locking

element (thread lock compound, patch etc.) is to be used.

Grade Class

Grade 8

Grade 5 or 8

Grade 10.9

Anti-rotation Slots

Mounting

Anti-Rotation

See Anti-Roatation Examples on pages 8-14