Warner Electric TG-2000 MagStop Clutch_Brake User Manual

Page 16

16

Warner Electric • 800-825-9050

P-1177 • 819-0457

Electrical Evaluation

Step 1. How to Measure Clutch Coil resistance

(See Figure 5)

1. Turn engine and PTO switch off.

2. Disconnect clutch at clutch connector.

3. Select meter setting for ohm reading.

4. Connect meter leads to clutch.

5. Check meter reading and refer to the chart

below for correct clutch resistance reading.

(values are @ 68°F.)

If reading falls in acceptable range proceed

to step 2, if not replace the clutch.

Figure 5

Resistance Measurement

Table 1

Resistance

Torque

at 70˚ F

Model

(ft.-lb.) Nom. Nm

(ohms) ±5%

MS-60

60

81

7.18

MS-80

80

108

3.68

TG2K-125

125

169

2.84

CMS-150

150

203

2.47

CMS-175

175

237

2.30

CMS-200

200

271

1.84

Note: If bench tested with 12 volts applied,

armature may not pull away from brakepoles.

Rotational motion is required to engage clutch.

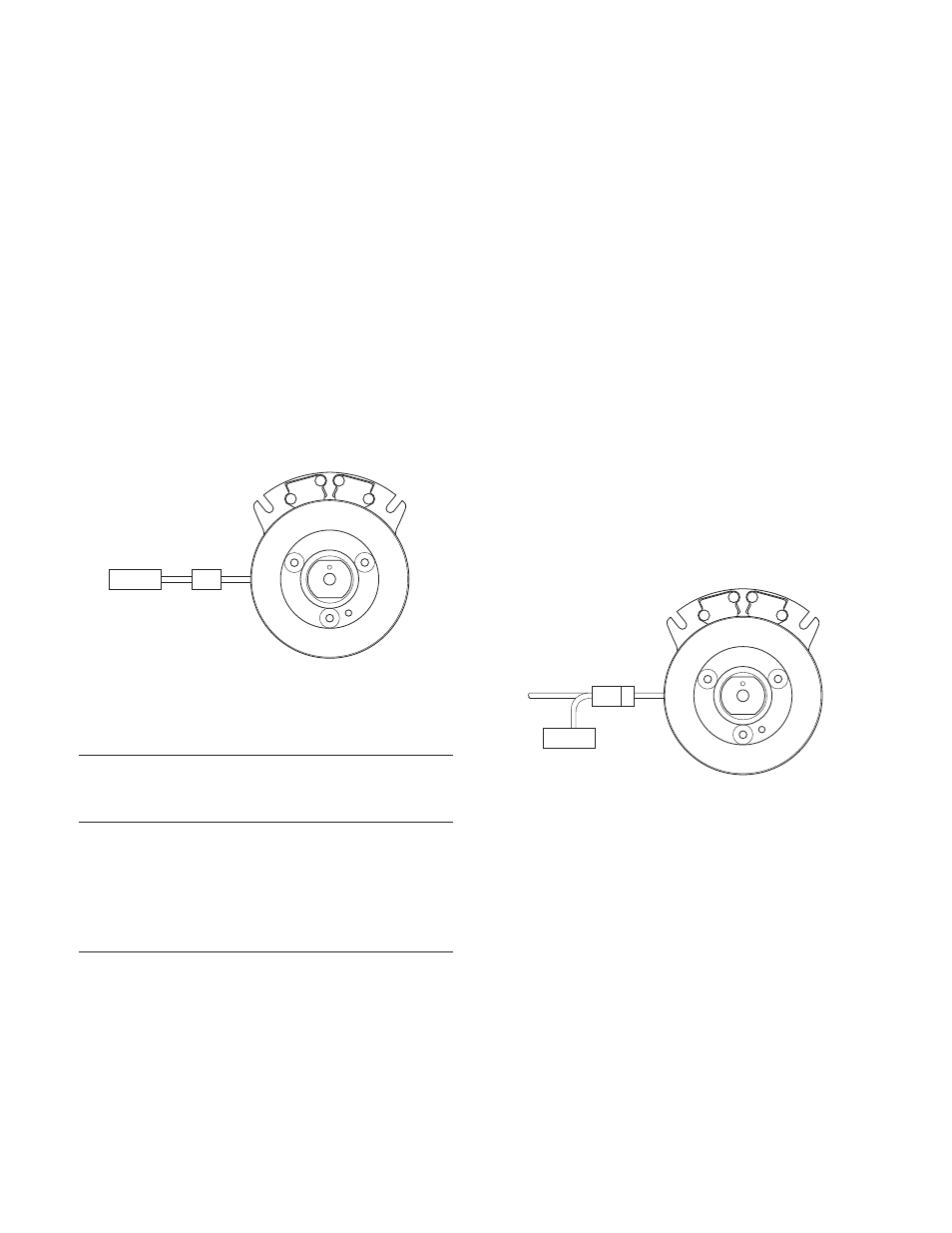

Figure 6

Voltage Measurement

Meter

Meter

Step 2. Measure the supply voltage at the clutch

(See Figure 6)

1. Turn engine off.

2. Connect meter leads at the clutch connector.

3. Select meter setting for voltage reading.

4. Make sure wires will not become entangled

in rotating components of clutch.

5. Start engine and engage PTO switch.

6. Measure voltage across the leads at

the connectors.

7. Voltage should be 12-14 volts DC. If clutch

still fails to operate, replace clutch.

8. If voltage is not within 12-14 volt range

consult EOM’s service manual.