Troubleshooting - electrical, Troubleshooting - mechanical, Electrical coil data – Warner Electric Gen 2 Clutch_Electrically Released Brake UniModule UM-50FBC, UM-100FBC, UM-180FBC User Manual

Page 7

of the power supply to the positive (red)

lead of the brake and the negative lead of

the power supply to the negative (black)

lead of the brake.

2. Connect a volt-meter to measure the

voltage applied across the brake.

3. Adjust the power supply to its lowest

possible output, and then energize the

power supply to apply power to the brake

only.

4. Starting from the low voltage point, slowly

increase the applied voltage while visually

watching the brake armature through one

of the vent slots and fan slot on either side

of the module until the brake armature

disengages from the brake magnet. Note

and record this voltage reading.

5. Add twenty (20) volts for a 90 volt brake

and five (5) volts for a 24 volt brake to this

reading and set the supply to this level.

This will be the proper release voltage for

your setup.

6. With the brake energized, spin the output

shaft by hand to insure that it turns freely.

If a scraping sound is noted when the

output shaft is spun, it means an

armature is dragging slightly. This needs to

be corrected by repeating brake release

adjustment steps 1-5 above and/or

performing armature airgap adjustment as

described in the Troubleshooting –

Mechanical section of this instruction.

Troubleshooting - Electrical

If a UniModule is not functioning properly it is

best to check for these problems before

replacing it.

A standard UniModule FBC clutch/brake

requires DC power to function. If power is not

reaching the clutch or brake, the clutch will

not engage and the brake will not disengage.

A good practice to follow is to check for

power at the lead wires to the clutch or brake

using a voltmeter.

• If power is present in the proper voltage

and current, then skip ahead to the

Mechanical Troubleshooting section.

• If power is not present, inspect the lead

wires for breaks or cuts.

• If the wires are intact, the problem may

be with the power supply or the switch.

• Using a voltmeter, check to see that

voltage is leaving the power supply and

that the switch is sending power to the

clutch or brake.

• Finally, if there is no power leaving the

switch or power supply, check the

incoming AC power to ensure that it is

reaching the power supply.

Troubleshooting - Mechanical

Both clutch and FB brake armatures are

equipped with an Autogap

TM

assembly that

maintains the proper airgap between friction

faces through the life of the product. Each

UniModule is airgap adjusted and pre-

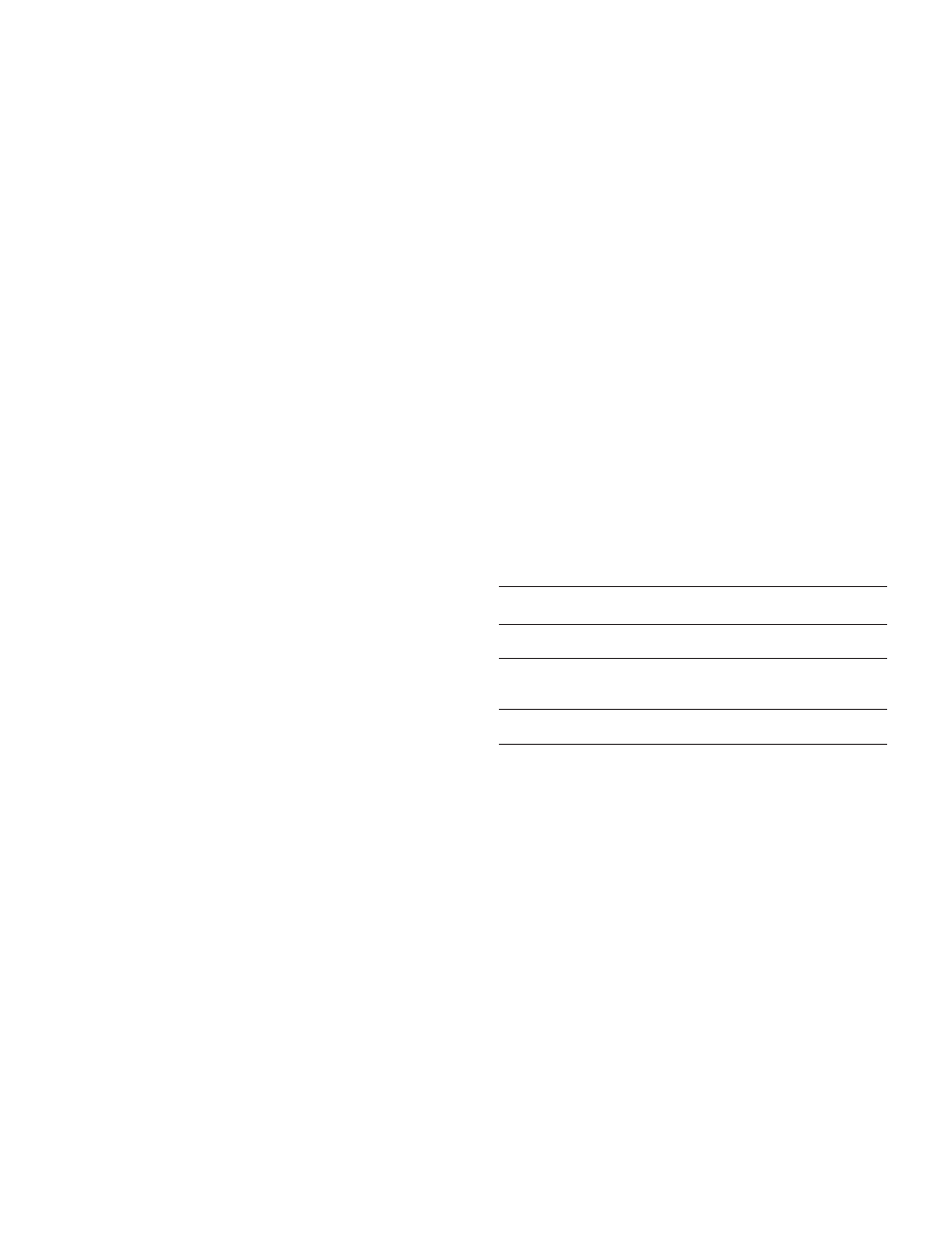

Electrical Coil Data

Clutch

Brake

Clutch

Brake

Voltage–D.C.

90

90

24

24

Resistance

UM-50

452

429

31.8

28.8

(OHMS)

UM-100/180

392

308

26.7

21.7

Current

UM-50

.20

.21

.76

.83

(Ampheres)

UM-100/180

.23

.29

.90

1.1

Power

UM-50

18

19

19

20

(WATTS)

UM-100/180

21

27

22

27

Coil Build Up UM-50

52

40

52

40

Warner Electric • 800-825-9050

P-273-9 • 819-0530

7